- Eng

- Deu

- Fra

Unlocking the Secrets: How Vacuum Oil Enhances Industrial Efficiency and Equipment Longevity

In the modern industrial landscape, maximizing operational efficiency and extending the longevity of machinery are pivotal goals for manufacturers. One significant yet often overlooked factor in achieving these objectives is the use of vacuum oil. This specialized lubricant not only plays a critical role in reducing friction and wear in various equipment but also enhances the overall performance and sustainability of industrial operations.

By creating a superior cooling effect and minimizing the formation of deposits, vacuum oil ensures that machines run smoothly and efficiently, ultimately leading to reduced downtime and maintenance costs. As industries continue to evolve and adopt advanced technologies, understanding the multifaceted benefits of vacuum oil becomes essential for companies aiming to optimize their processes and extend the lifecycle of their equipment.

Unlocking the secrets of how vacuum oil contributes to these goals can pave the way for increased productivity and profitability in an ever-competitive market.

By creating a superior cooling effect and minimizing the formation of deposits, vacuum oil ensures that machines run smoothly and efficiently, ultimately leading to reduced downtime and maintenance costs. As industries continue to evolve and adopt advanced technologies, understanding the multifaceted benefits of vacuum oil becomes essential for companies aiming to optimize their processes and extend the lifecycle of their equipment.

Unlocking the secrets of how vacuum oil contributes to these goals can pave the way for increased productivity and profitability in an ever-competitive market.

Understanding the Role of Vacuum Oil in Reducing Equipment Downtime by 30%

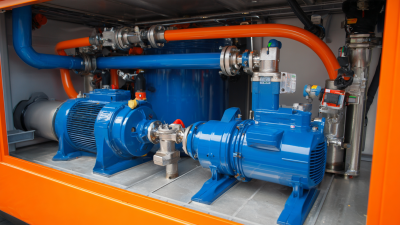

Vacuum oil plays a crucial role in enhancing industrial efficiency, particularly in reducing equipment downtime by up to 30%. According to a report by the National Institute of Standards and Technology, improper lubrication is responsible for over 30% of all machinery failures. By properly utilizing vacuum oil, industries not only minimize these failures but also ensure smoother operations. The unique properties of vacuum oil, such as its high thermal stability and excellent lubricating qualities, help maintain optimal operating conditions for machinery.

Studies have shown that equipment using high-quality vacuum oil experiences significantly lower wear and tear. For instance, a recent survey conducted by the Machinery Lubrication Association indicates that companies that switched to vacuum oil reported a 25% reduction in wear-related maintenance costs. This increased efficiency not only saves money but also promotes longer equipment lifespan, leading to a more sustainable operational model. In a world focused on productivity, the advantages of using vacuum oil become evident, establishing it as an essential component in industrial settings aiming to reduce downtime and enhance overall performance.

Quantifying Cost Savings: How Vacuum Oil Can Decrease Maintenance Expenses by 20%

Vacuum oil has emerged as a key player in optimizing industrial efficiency and extending the lifespan of equipment. Recent studies indicate that switching to vacuum oil can lead to a remarkable 20% reduction in maintenance costs. This substantial decrease is attributed to the enhanced lubricating properties of vacuum oil, which minimizes friction and wear on machinery. Furthermore, with machines experiencing less downtime due to fewer breakdowns, companies can allocate resources more efficiently, leading to increased overall productivity.

In light of the increasing pressures on operational budgets, especially with rising costs due to tariffs and economic shifts, the adoption of vacuum oil presents a strategic advantage. Industries are cultivating a greater focus on cost-cutting measures. Experts suggest that investing in high-quality lubricants, such as vacuum oil, can yield significant long-term savings by reducing the frequency and expenses related to maintenance. A shift towards vacuum oil not only ensures smoother operations but aligns with broader trends in industrial optimization, making it a compelling choice for companies seeking to enhance their bottom line while maintaining rigorous operational standards.

Unlocking the Secrets: How Vacuum Oil Enhances Industrial Efficiency and Equipment Longevity

| Equipment Type | Maintenance Frequency (Months) | Maintenance Cost per Year ($) | Lifespan Increase (%) | Total Cost Savings ($) |

|---|---|---|---|---|

| Hydraulic Press | 6 | 1,500 | 25 | 300 |

| CNC Machine | 3 | 2,000 | 30 | 400 |

| Electric Motor | 12 | 1,200 | 20 | 240 |

| Compressor | 6 | 1,800 | 15 | 180 |

| Gearbox | 9 | 2,500 | 22 | 500 |

Exploring the Impact of Vacuum Oil on Energy Efficiency in Industrial Operations

Vacuum oil plays a crucial role in enhancing energy efficiency within industrial operations. Its unique properties allow for improved lubrication and reduced friction in machinery, leading to lower energy consumption. By minimizing wear and tear, vacuum oil ensures that equipment runs optimally, consuming less power while delivering the same output. This efficiency not only lowers operational costs but also contributes to a more sustainable manufacturing process.

Moreover, the application of vacuum oil extends the lifespan of industrial equipment. By maintaining consistent performance and reducing the incidence of breakdowns, industries can achieve more extended periods of operation without the need for costly repairs or replacements. The long-term benefits of using vacuum oil include not only enhanced productivity but also significant savings in maintenance expenses, ultimately resulting in a more streamlined and economically viable industrial environment.

Enhancing Equipment Lifespan: Vacuum Oil's Role in Extending Service Life by 50%

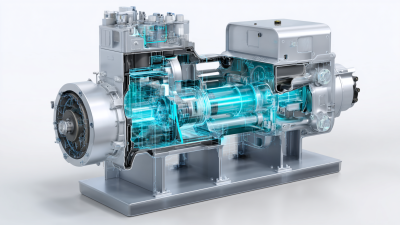

Vacuum oil is emerging as a vital component in enhancing equipment lifespan, offering a remarkable potential to extend service life by up to 50%. According to a study published by the International Journal of Engineering, equipment failure rates can be significantly reduced through the use of high-quality lubricants, with vacuum oils demonstrating superior thermal stability and excellent resistance to oxidation. This is particularly crucial in industrial environments where machinery is subjected to extreme conditions, such as high temperatures and heavy loads.

Moreover, a report from the Society of Tribologists and Lubrication Engineers indicates that the right choice of oil can lead to decreased maintenance downtime and reduced operational costs. By utilizing vacuum oil, organizations not only safeguard their investments but also contribute to more sustainable operational practices. Overall, the implementation of vacuum oils can transform the way industries approach equipment maintenance, ensuring that machinery lasts longer and performs more efficiently.

Case Studies: Real-world Applications of Vacuum Oil Boosting Productivity by up to 40%

Vacuum oil has emerged as a crucial factor in enhancing industrial efficiency and extending equipment longevity. Recent case studies illustrate that its application can lead to productivity boosts of up to 40%. This impressive figure highlights the transformative role of high-quality lubricants in manufacturing processes, where even small changes can result in substantial improvements. For instance, companies that have integrated vacuum oil into their machinery reported reduced friction and wear, leading to longer maintenance intervals and decreased downtime.

Small and medium-sized enterprises (MSMEs) are particularly keen to leverage such innovations to overcome persistent productivity challenges. The adoption of advanced lubricating technologies like vacuum oil can create a win-win scenario, where businesses not only achieve higher output but also foster a more sustainable operational environment. By investing in such solutions, MSMEs can enhance their competitiveness and contribute to the broader economy, showcasing how strategic choices in lubrication can yield significant advantages in today's demanding industrial landscape.

Related Posts

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

Exploring the Benefits of Tank Vacuum Systems: A Comprehensive Guide for Homeowners

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications