- Eng

- Deu

- Fra

Exploring Vacuum Oil: Key Benefits and Industry Trends Influencing Machinery Performance

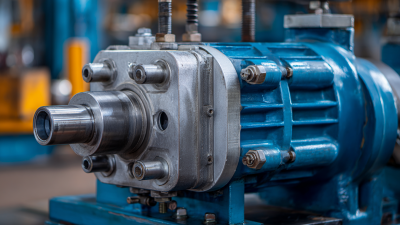

In the world of industrial machinery, the importance of lubrication cannot be overstated, and one crucial product emerging at the forefront is vacuum oil. This specialized lubricant is designed to create an optimal operating environment, enhancing the efficiency and longevity of various machines. As industries continuously seek ways to improve machinery performance, understanding the key benefits and evolving trends related to vacuum oil becomes essential. The unique properties of vacuum oil not only facilitate superior lubrication under extreme conditions but also contribute to reduced maintenance costs and increased productivity. As manufacturers face growing pressures to enhance performance while adhering to sustainability standards, the adoption of advanced lubrication solutions, such as vacuum oil, is gaining momentum. This article explores the multifaceted advantages of vacuum oil and delves into the current industry trends impacting its application, providing insights into why this innovative lubricant is becoming a preferred choice for modern machinery operations.

Understanding Vacuum Oil: Its Role in Enhancing Machinery Efficiency

Vacuum oil plays a crucial role in enhancing machinery efficiency across various industries. By creating a low-viscosity environment, vacuum oils reduce friction and wear, thereby extending the lifespan of machinery components. According to a report by the National Lubricating Grease Institute, optimal lubrication can improve equipment life by up to 50%, which is significant for industries reliant on high-performance machinery. Additionally, vacuum oils' ability to withstand high temperatures means they maintain stability and performance under demanding conditions, a characteristic that is particularly critical in sectors such as manufacturing and automotive.

Moreover, the increasing demand for energy-efficient solutions is driving the growth of vacuum oil usage. Data from a recent market analysis shows that the demand for high-quality vacuum oils has risen by 20% annually, as companies seek to minimize energy consumption and reduce operational costs. This trend aligns with the broader industry movement towards sustainability, where enhanced machinery efficiency not only translates to economic benefits but also contributes to lower carbon footprints. As technological advancements continue to emerge, understanding the role of vacuum oil in improving machinery performance will remain essential for businesses aiming to stay competitive in their sectors.

Key Benefits of Using Vacuum Oil in Various Industrial Applications

Vacuum oil plays a pivotal role in enhancing machinery performance across various industrial applications. Its low volatility and excellent thermal stability make it particularly effective for high-temperature environments. According to a recent report from the Machinery Lubrication Association, vacuum oil can extend equipment lifespan by 25% when compared to conventional oils, significantly reducing maintenance costs and downtime. This characteristic is essential in sectors such as manufacturing and energy, where operational efficiency is critical.

Moreover, the lubricating properties of vacuum oil contribute to improved efficiency in process equipment. A study by the International Journal of Industrial Lubrication found that using vacuum oil leads to a 15% reduction in energy consumption in hydraulic systems due to its superior ability to reduce friction. This not only lowers operational costs but also supports sustainability initiatives by minimizing energy waste. As industries continue to embrace advanced lubricants, vacuum oil is garnering attention for its ability to meet the evolving demands of high-performance machinery.

Key Benefits of Using Vacuum Oil in Various Industrial Applications

Recent Industry Trends Shaping the Future of Vacuum Oil Usage

Recent trends in the vacuum oil industry are significantly impacting machinery performance and operational efficiency across various sectors. A report from MarketsandMarkets indicates that the global vacuum oil market is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2028, driven by increasing demand for efficient energy solutions and innovations in lubricants. This growth is particularly prominent in industries such as automotive and manufacturing, where the need for high-performance machinery is crucial for productivity.

Furthermore, advancements in technology have led to the development of synthetic vacuum oils, which offer superior thermal stability and extended service life compared to conventional oils. For instance, a study by Technavio highlights that the adoption of synthetic vacuum oils is expected to rise by 20% in the next five years, as businesses seek to optimize maintenance schedules and reduce downtime. These trends reflect a broader shift towards sustainability and efficiency, as companies recognize the long-term cost benefits and environmental advantages of investing in high-quality vacuum oils.

Tips for Selecting the Right Vacuum Oil for Your Machinery Needs

When selecting the right vacuum oil for your machinery, it is essential to consider several critical factors that directly influence performance and longevity. A comprehensive analysis by the International Journal of Manufacturing Technology shows that using high-quality vacuum oils can reduce machinery wear by up to 30%, thereby improving overall efficiency. It is important to match the oil viscosity grade with your machinery's specifications, as improper viscosity can lead to inadequate lubrication, resulting in increased downtime and maintenance costs.

Additionally, operators should evaluate the oil's resistance to thermal degradation and chemical stability. Reports indicate that oils with superior thermal stability can maintain performance levels even at temperatures exceeding 200°C. Furthermore, selecting oils with lower susceptibility to oxidation extends the maintenance intervals, reducing operational disruptions. When choosing vacuum oil, considering these properties alongside the specific operational conditions of your machinery can ultimately lead to enhanced productivity and cost-effectiveness.

Best Practices for Maintaining and Optimizing Vacuum Oil Performance

When it comes to maintaining and optimizing vacuum oil performance, adhering to best practices is crucial for machinery longevity and efficiency. One fundamental practice is regular oil analysis. This involves monitoring the oil's viscosity, contaminants, and overall condition, which can help anticipate potential issues before they escalate. By proactively managing oil quality, operators can ensure smooth operational processes and reduce unexpected downtime.

**Tip:** Implement a scheduled routine for oil sampling and testing. Regular assessments can inform decisions on oil replacement and help maintain optimal performance levels.

Another key aspect is proper filtration. Ensuring that your vacuum oil is free from impurities can dramatically enhance its performance. Utilizing high-quality filters and routinely checking for clogs can prevent damage to machinery and prolong the life of the oil. Keeping the oil clean directly correlates with the efficiency of the machinery and the consistency of operations.

**Tip:** Invest in advanced filtration systems designed for your specific machinery needs. These systems can significantly reduce contaminants and improve overall oil performance, leading to better reliability in production processes.

Exploring Vacuum Oil: Key Benefits and Industry Trends Influencing Machinery Performance - Best Practices for Maintaining and Optimizing Vacuum Oil Performance

| Dimension | Description | Industry Trend | Best Practice |

|---|---|---|---|

| Thermal Stability | Resistance to thermal degradation, ensuring optimal performance. | Growing demand for high-temperature applications. | Regular testing of thermal properties. |

| Viscosity | Optimal flow characteristics for machinery operation. | Trend towards lower viscosity oils for efficiency. | Monitor viscosity regularly to maintain performance. |

| Oxidation Resistance | Prevention of oil degradation during use. | Increase in environmentally friendly oils. | Implement oil filtration systems to prolong life. |

| Demulsibility | Ability to separate from water, essential for machinery. | Focus on moisture management in oils. | Conduct regular checks for moisture content. |

| Additives | Enhancers for performance and protection of machinery. | Trend toward specialty additives for specific applications. | Select oils with the right additives for the application. |

Related Posts

-

Unlocking the Secrets: How Vacuum Oil Enhances Industrial Efficiency and Equipment Longevity

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

Understanding the Efficiency and Applications of Rotary Vane Vacuum Pumps in Modern Industries

-

Understanding Waste Pumps How They Work and Their Importance in Modern Waste Management

-

The Essential Guide to Understanding Oil Vacuum Pumps and Their Applications in Industry

-

Understanding the Future of Energy: How Oil Pumps Power the Transition to Renewable Resources