- Eng

- Deu

- Fra

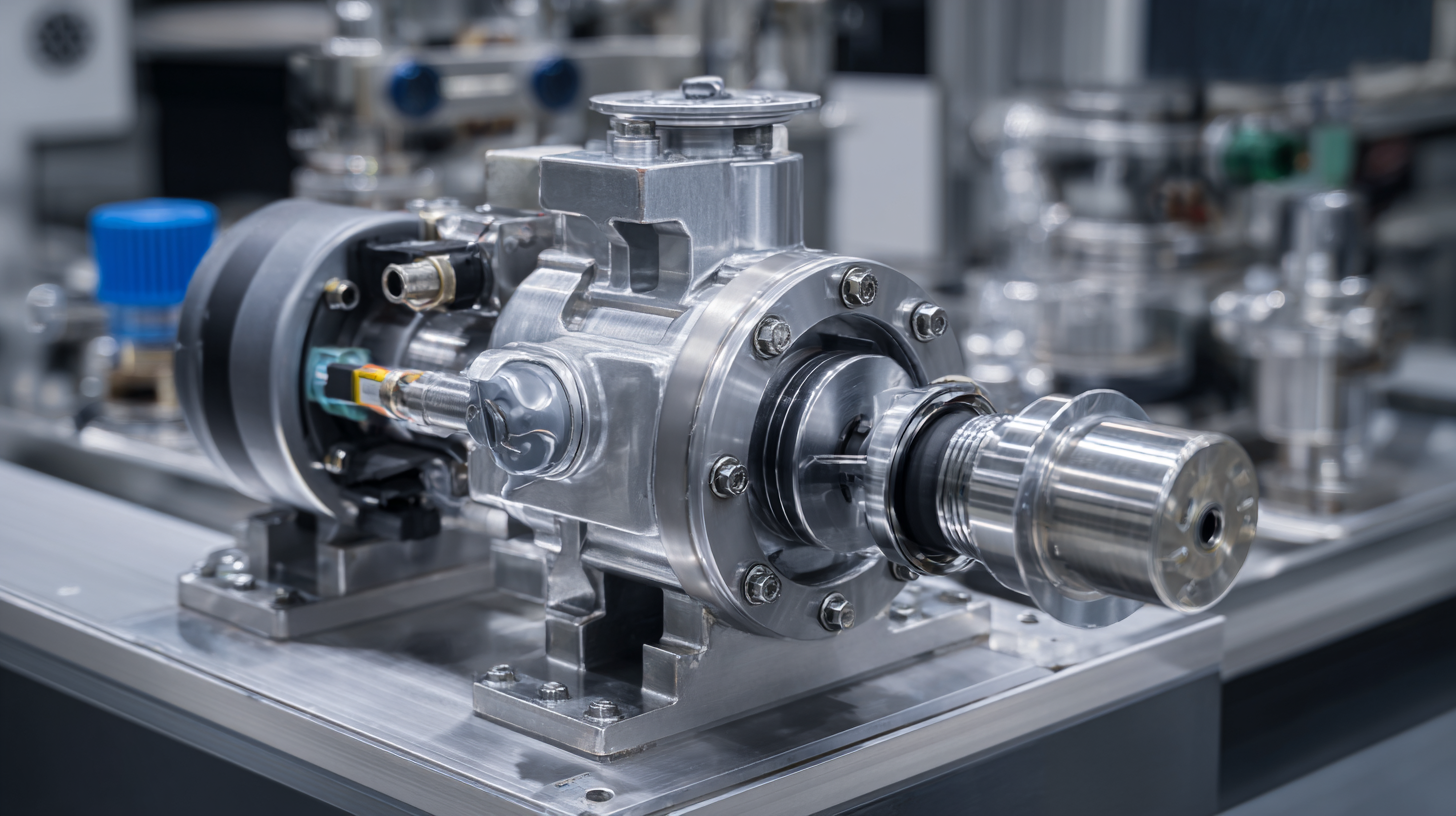

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

In the realm of industrial applications, the rotary vane vacuum pump stands out as a crucial component for various processes, due to its efficiency and reliability. According to a recent report by Research and Markets, the global vacuum pump market is projected to reach $4.9 billion by 2026, with rotary vane vacuum pumps expected to play a significant role in this growth, primarily driven by their effectiveness in creating low-pressure environments essential for applications ranging from food packaging to chemical processing.

The simplicity of the rotary design, combined with its ability to handle both gases and vapors, makes it a preferred choice among industries gravitating towards automation and energy efficiency. As companies strive for optimized operations, understanding the science behind the rotary vane vacuum pump not only empowers engineers and technicians but also maximizes the potential for productivity and sustainability within industrial ecosystems.

In the realm of industrial applications, the rotary vane vacuum pump stands out as a crucial component for various processes, due to its efficiency and reliability. According to a recent report by Research and Markets, the global vacuum pump market is projected to reach $4.9 billion by 2026, with rotary vane vacuum pumps expected to play a significant role in this growth, primarily driven by their effectiveness in creating low-pressure environments essential for applications ranging from food packaging to chemical processing.

The simplicity of the rotary design, combined with its ability to handle both gases and vapors, makes it a preferred choice among industries gravitating towards automation and energy efficiency. As companies strive for optimized operations, understanding the science behind the rotary vane vacuum pump not only empowers engineers and technicians but also maximizes the potential for productivity and sustainability within industrial ecosystems.

Fundamentals of Rotary Vane Vacuum Pump Operation in Industry

Rotary vane vacuum pumps are essential in various industrial applications due to their efficiency and reliability. The fundamental operation of these pumps involves the rotation of vanes within a cylindrical chamber, creating a series of expanding and contracting volumes. As the vanes rotate, they trap air or gases, effectively creating a vacuum. The simplicity of this mechanism allows for consistent performance even under varying operational conditions.

Rotary vane vacuum pumps are essential in various industrial applications due to their efficiency and reliability. The fundamental operation of these pumps involves the rotation of vanes within a cylindrical chamber, creating a series of expanding and contracting volumes. As the vanes rotate, they trap air or gases, effectively creating a vacuum. The simplicity of this mechanism allows for consistent performance even under varying operational conditions.

Tips: Regular maintenance is crucial for optimizing the performance of rotary vane vacuum pumps. Ensure that the oil levels are checked frequently, as insufficient oil can lead to increased wear and reduced efficiency. Additionally, periodic inspection of the vanes is necessary to prevent any potential failures or drop in vacuum levels.

In industrial settings, understanding the nuances of rotary vane vacuum pumps can lead to significant improvements in productivity. These pumps are particularly advantageous in applications such as pharmaceutical manufacturing and food packaging, where maintaining a specific vacuum level is critical. Proper integration and operational strategies enhance their performance, making them a preferred choice for many industries.

Tips: When selecting a rotary vane vacuum pump for your application, consider the required vacuum level and flow rate to ensure compatibility with your processes. Implementing a monitoring system can also help in detecting performance issues early on, thus avoiding unplanned downtime.

Key Advantages of Rotary Vane Vacuum Pumps Over Alternatives

Rotary vane vacuum pumps have gained significant traction in various industrial applications due to their unique advantages over alternative vacuum technologies. One of the key benefits is their ability to provide a high level of vacuum at relatively low operational costs. According to a report by the Global Vacuum Pump Market, rotary vane vacuum pumps are estimated to account for around 25% of the overall vacuum pump market share in 2022, indicating their wide acceptance in sectors such as food packaging, pharmaceuticals, and electronics manufacturing.

Additionally, rotary vane vacuum pumps are known for their reliability and ease of maintenance. They can operate continuously for extended periods without significant performance degradation, which is crucial in industrial settings where downtime can translate to substantial revenue losses. Research shows that these pumps can maintain consistent performance levels with minimal energy consumption—approximately 20-30% less than comparable oil-sealed pumps—making them not only a cost-effective choice but also an environmentally friendly option that adheres to modern sustainability practices.

In terms of versatility, rotary vane vacuum pumps are capable of handling a wide range of applications, from low to high vacuum levels. This adaptability, combined with their compact design, allows for easy integration into existing systems, attracting industries that require flexible and efficient vacuum solutions. As industries move towards more efficient and reliable technologies, the role of rotary vane vacuum pumps becomes increasingly vital.

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications - Key Advantages of Rotary Vane Vacuum Pumps Over Alternatives

| Dimension | Rotary Vane Vacuum Pumps | Alternative Technologies |

|---|---|---|

| Efficiency | 70-90% | 50-80% |

| Maintenance Frequency | Low (annual maintenance) | Moderate (semi-annual maintenance) |

| Noise Level | Quiet (50-70 dB) | Loud (70-90 dB) |

| Initial Cost | Moderate | Low to Moderate |

| Operating Temperature Range | -20°C to 60°C | -10°C to 50°C |

| Applications | Food processing, packaging, and chemical industries | General industrial and automotive applications |

| Lifespan | Up to 15 years | 5-10 years |

Application-Specific Uses of Rotary Vane Vacuum Pumps in Various Industries

Rotary vane vacuum pumps are widely used across various industries due to their reliability and efficiency in creating a vacuum. In the packaging industry, these pumps play a critical role in ensuring that products are sealed tightly, preventing contamination and prolonging shelf life. By removing air from packaging, rotary vane vacuum pumps help maintain product integrity, making them essential for food preservation and pharmaceuticals, where sterility is paramount.

In the automotive sector, rotary vane vacuum pumps are utilized for tasks such as brake boosters and emissions control. Their ability to generate a strong vacuum allows for effective operation of safety features and contributes to achieving stringent emission standards. Additionally, these pumps are employed in the manufacturing of electronic components, where cleanroom environments are necessary. The efficient vacuum generation helps remove particulates and moisture, ensuring high-quality production and reliability in final products. Each application highlights the versatility and efficiency of rotary vane vacuum pumps in meeting specific industrial requirements.

Maintenance Best Practices for Optimizing Rotary Vane Pump Performance

To ensure optimal performance of rotary vane vacuum pumps in industrial applications, regular maintenance is critical. One of the best practices is to perform routine inspections and replace worn-out vanes promptly. The vanes are crucial for creating the vacuum pressure, and any deterioration can significantly impact efficiency. Monitoring the lubricant levels and replacing it as per the manufacturer's guidelines will also prevent overheating and wear, thus extending the pump's lifespan.

Another crucial aspect of maintenance is ensuring that the intake filters are clean and free from debris. Clogged filters can lead to increased strain on the pump and reduce suction efficiency. Additionally, scheduling periodic system checks to examine seals, gaskets, and other components will help identify potential issues before they escalate. Training operators on how to detect unusual noises or performance dips can further enhance the reliability of rotary vane pumps, ensuring that they operate smoothly and efficiently in demanding industrial settings.

Rotary Vane Vacuum Pumps Performance Analysis

This chart illustrates the maintenance frequency and efficiency level of rotary vane vacuum pumps in industrial applications. The data reflects average performance metrics based on operational guidelines and best practices.

Future Trends and Innovations in Rotary Vane Vacuum Pump Technology

The evolving landscape of rotary vane vacuum pump technology is characterized by innovative designs that enhance efficiency and reliability in industrial applications. Future trends indicate a shift towards smart vacuum systems that incorporate IoT (Internet of Things) capabilities, enabling real-time monitoring and remote control. These advancements will allow for predictive maintenance, reducing downtime and operational costs significantly. By harnessing data analytics, manufacturers can optimize performance and extend the lifespan of their equipment.

In addition to smart technology, developments in materials science are driving innovation in rotary vane pumps. The use of advanced composites and coatings can reduce wear and tear, leading to longer service intervals and better performance under demanding conditions. This shift not only increases the operational efficiency of vacuum systems but also contributes to sustainability, as improved durability means less frequent replacements and reduced material waste. As industries continue to seek more efficient and environmentally friendly solutions, rotary vane vacuum pump technology is poised to play a pivotal role in shaping the future of industrial processes.