- Eng

- Deu

- Fra

The Essential Guide to Understanding Oil Vacuum Pumps and Their Applications in Industry

In the evolving landscape of industrial applications, oil vacuum pumps have emerged as fundamental tools that enhance operational efficiency and reliability. According to a recent market report by Grand View Research, the global oil vacuum pump market is projected to reach USD 3.56 billion by 2025, indicating a compound annual growth rate (CAGR) of 5.8%. These pumps play a crucial role across various sectors, including automotive, manufacturing, and food processing, where the need for reliable vacuum solutions is paramount. This guide aims to provide a comprehensive understanding of oil vacuum pumps, detailing their mechanisms, benefits, and practical applications. By exploring the diverse functionalities and advancements in oil vacuum pump technology, industry professionals can make informed decisions to optimize their processes and maintain competitiveness in today's demanding market.

Understanding the Basics: What is an Oil Vacuum Pump?

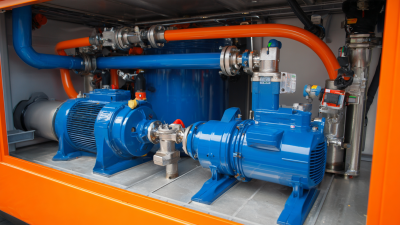

Oil vacuum pumps are critical components in numerous industrial applications, providing essential functionalities from maintaining product purity to enhancing process efficiency. An oil vacuum pump operates by using a liquid seal created by oil within the pump chambers, effectively preventing air and contaminants from entering the system. This technology is essential in applications like chemical processing, pharmaceuticals, and food packaging, where a reliable vacuum environment is paramount.

Recent industry statistics indicate a growing demand for oil vacuum pumps, driven by the expanding chemical and pharmaceutical sectors. The global market for vacuum pumps is projected to witness significant growth, with emerging demands noted in sectors focusing on automation and sustainable practices. According to a report by Industry Research Biz, the market is expected to grow steadily, with specific forecasts indicating an increase in oil-sealed vacuum technology adoption due to its reliability and efficiency in handling volatile substances and temperatures. The ongoing evolution of smart vacuum solutions is also paving the way for more innovative applications, indicating a shift towards integrated systems that improve performance and reduce operational costs.

Key Features to Look For When Choosing an Oil Vacuum Pump

When selecting an oil vacuum pump for industrial applications, several key features should be prioritized to ensure optimal performance and longevity. First and foremost, consider the pump’s capacity and efficiency. A pump that can handle the required volume without excessive energy consumption will not only save costs but also enhance productivity. Look for models that provide specifications on their ultimate pressure levels and flow rates, as these figures will directly influence the effectiveness of the pump in various tasks.

Another crucial feature is the construction material and design. An oil vacuum pump made from durable materials can withstand harsh industrial conditions and resist wear and tear. It's also essential to assess the ease of maintenance; pumps that are designed for straightforward servicing can significantly reduce downtime. Additionally, noise level can be an important consideration, especially in environments where sound pollution needs to be minimized. By focusing on these essential features, you can choose an oil vacuum pump that meets both operational requirements and industry standards.

Top 5 Industrial Applications of Oil Vacuum Pumps You Should Know

Oil vacuum pumps play a critical role across various industrial sectors, with unique applications that enhance operational efficiency. One of the most significant applications is in the semiconductor industry, where the demand for a controlled vacuum environment is paramount for manufacturing processes. Oil vacuum pumps create the necessary vacuum conditions that facilitate the production of high-quality semiconductor devices, thereby supporting the industry's growth.

Additionally, oil vacuum pumps are indispensable in the pharmaceutical sector, where they are used in processes like freeze drying and distillation. The ability to maintain a vacuum during these processes ensures the stability and effectiveness of sensitive compounds. Another crucial application lies in the chemical industry, where vacuum pumps are employed in the handling of volatile substances, preventing contamination and ensuring safety. As industries continue to innovate and expand, the importance of oil vacuum pumps remains unwavering, reflecting a trend towards increased domestic production capabilities in the vacuum pump market.

The Essential Guide to Understanding Oil Vacuum Pumps and Their Applications in Industry - Top 5 Industrial Applications of Oil Vacuum Pumps You Should Know

| Application | Description | Benefits | Common Industries |

|---|---|---|---|

| Food Processing | Used for packaging and preserving food items by creating vacuum conditions. | Extended shelf life, reduction of spoilage, improved taste. | Food and Beverage |

| Pharmaceuticals | Used in the manufacturing process to create a contaminant-free environment. | Enhanced product safety, consistent quality, compliance with regulations. | Pharmaceutical and Biotech |

| Electronics | Deployed in the manufacturing of electronic components to create vacuum packaging. | Prevention of oxidation, prolonged lifespan of components. | Electronics and Manufacturing |

| Chemical Processing | Utilized for solvent distillation and extraction processes. | Increased efficiency, reduced energy consumption, higher purity of products. | Chemical and Petrochemical |

| Metal Processing | Used in vacuum casting processes for high-quality metal products. | Improved material properties, reduced defects in casting. | Manufacturing and Metalworking |

Maintenance Tips for Extending the Lifespan of Oil Vacuum Pumps

Oil vacuum pumps play a crucial role in various industrial applications, from food processing to pharmaceuticals, ensuring that systems operate smoothly by removing air and other gases. However, like any mechanical equipment, their performance can decline over time if not properly maintained. According to a recent report from the International Society of Vacuum Technology, routine maintenance can extend a pump's lifespan by up to 50%, enhancing efficiency and reducing operational costs.

To keep oil vacuum pumps functioning optimally, consider these essential maintenance tips. First, regularly check and replace oil filters to prevent contamination and ensure effective lubrication. A study by the Vacuum Pump Manufacturer’s Association indicates that clean oil can contribute to a 15% increase in efficiency. Additionally, monitoring the pump's operating temperature is vital; keeping it within the manufacturer’s recommended range prevents overheating, which can shorten the pump's life significantly.

Another valuable tip is to conduct periodic inspections for leaks and wear. Utilizing vibration analysis can help identify underlying issues before they escalate, ensuring early intervention. Research shows that proactive maintenance not only improves reliability but also adds longevity to the equipment, translating into substantial savings for businesses in the long term.

Common Issues and Troubleshooting Techniques for Oil Vacuum Pumps

When dealing with oil vacuum pumps in industrial applications, a variety of common issues may arise that can significantly impair system performance. One prevalent problem is air entrainment, which occurs when air mixes with oil, compromising the vacuum efficiency. Studies suggest that nearly 80% of vacuum pump failures can be traced back to improper maintenance and air leaks in the system. Ensuring proper sealing and examining all connections can mitigate this issue.

Another critical concern involves pump overheating and subsequent oil breakdown. Continuous operation beyond the recommended temperature range can lead to diminished viscosity and evaporative losses. Regular monitoring and scheduled maintenance can help identify abnormal temperature fluctuations before they escalate into more significant issues. Additionally, a recent recall involving vacuum pumps revealed that out of 3.8 million units inspected, 15% showed insufficient vacuum power, highlighting the importance of rigorous testing and troubleshooting protocols in preventing operational failures.

By focusing on these common challenges and implementing proven troubleshooting techniques, industries can effectively enhance the reliability and lifespan of their oil vacuum pumps, ensuring optimal performance in various applications.

The Essential Guide to Understanding Oil Vacuum Pumps

This bar chart displays the efficiency of various oil vacuum pumps commonly used in industry. Understanding the efficiency of these pumps can help in troubleshooting and improving operational performance.