- Eng

- Deu

- Fra

Top Vane Pump Types for Efficient Fluid Management Solutions?

Efficient fluid management is crucial in various industries. One key component in this process is the vane pump. Vane pumps are known for their reliability and versatility. They are used in applications like hydraulic systems and fuel transfer.

Different vane pump types offer unique advantages. Some pumps excel in high-viscosity fluids. Others provide precise flow control. However, selecting the right type can be challenging. It requires understanding specific operational needs. Vane pumps also come with certain limitations that need consideration. Users might face issues like sensitivity to wear.

Exploring the various vane pump types helps in making informed decisions. The goal is to enhance efficiency and performance. Understanding these pumps can lead to better fluid management solutions. Ultimately, finding the right vane pump is a balance of benefits and challenges.

Types of Vane Pumps and Their Applications

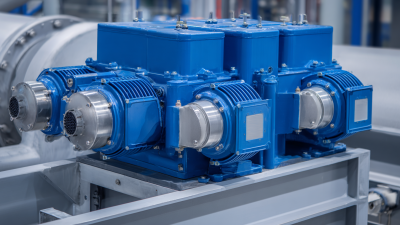

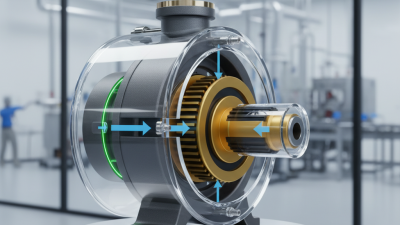

Vane pumps are essential in various industries for fluid management. They are known for their reliability and efficiency. Common types include rotary vane pumps and sliding vane pumps. Each type serves different applications. For example, rotary vane pumps are often used in hydraulic systems, while sliding vane pumps excel in transferring volatile liquids.

A study by the Hydraulic Institute shows that vane pumps account for about 15% of the global pump market. Their operational efficiency can exceed 90%. However, many users overlook maintenance, which impacts performance. Regular checks can help prolong their lifespan. For example, monitoring the wear on vanes can prevent costly downtime.

Different industries utilize vane pumps uniquely. In the oil and gas sector, these pumps handle high-viscosity fluids. In pharmaceuticals, they transfer sensitive materials. Despite their advantages, inconsistencies in fluid delivery can arise. Addressing these issues often requires a deeper understanding of flow dynamics. Proper selection and application are crucial for optimizing performance. Users must reflect on their specific needs before choosing a pump type.

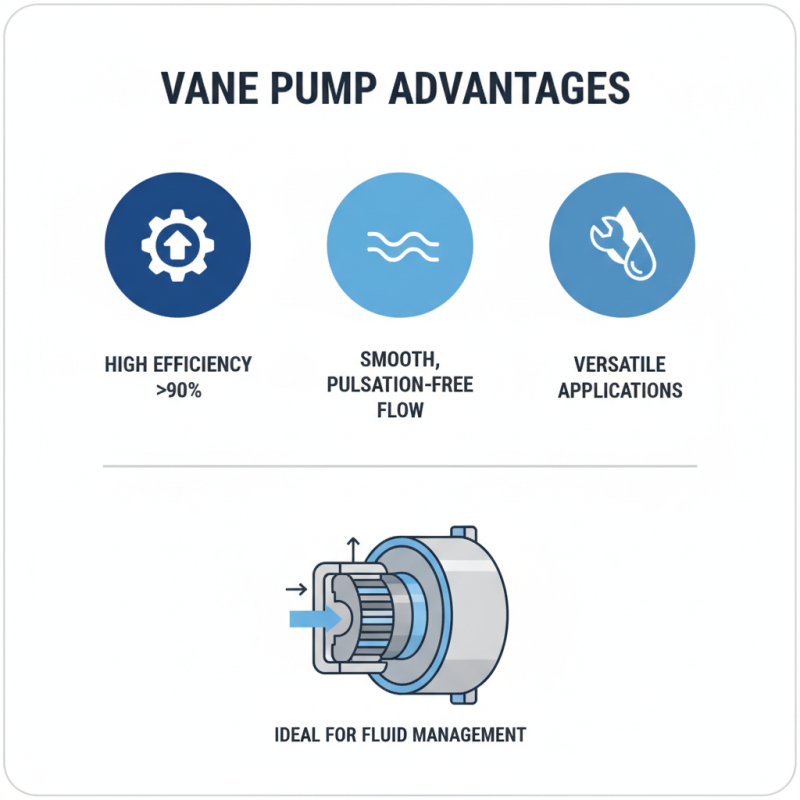

Advantages of Vane Pumps for Fluid Management

Vane pumps offer significant advantages in fluid management systems. According to recent industry publications, vane pumps can achieve efficiencies of over 90%. This high-performance capability makes them ideal for various applications. Their design allows for smooth, pulsation-free fluid flow, which is a crucial feature for sensitive processes.

One major benefit of vane pumps is their versatility. These pumps handle different liquids, including those with varying viscosities. This adaptability means fewer pumps are needed for diverse tasks, potentially lowering operational costs. However, it is essential to consider the maintenance needs, as improper care can lead to efficiency losses.

Tips: Regular inspection is vital. Schedule routine checks to avoid unexpected breakdowns. Additionally, consider environmental factors that might affect pump performance. Keeping pumps in optimal conditions can extend their lifespan significantly. Remember, even the best technology requires thoughtful management to operate efficiently.

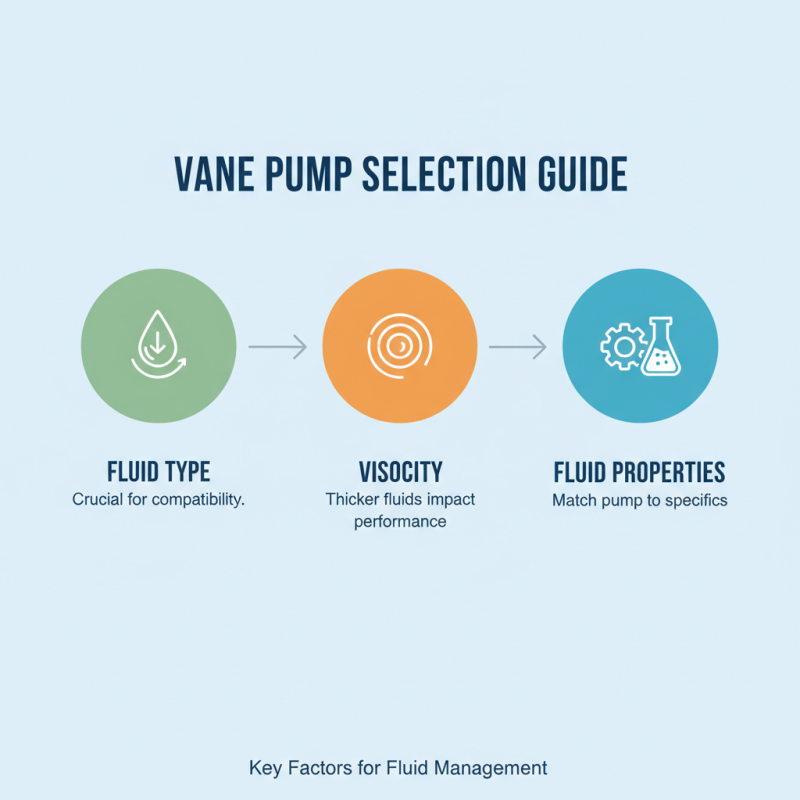

Factors to Consider When Selecting a Vane Pump

When selecting a vane pump for fluid management, several factors come into play. The type of fluid is crucial. Some fluids are thicker than others. Viscosity affects pump performance significantly. A pump that works well with water may struggle with oil. Always consider the specific fluid properties.

Another essential factor is the required flow rate. Pumps deliver different flow rates based on their design. If the flow rate is too low, system efficiency decreases. Too high a flow rate can lead to operational issues. Knowing your system's needs is vital for optimal performance.

**Tips:** Evaluate compatibility with fluids. Check if your chosen pump can handle the specific conditions. Look into installation space. Pumps need adequate room for maintenance and operation. Sometimes, systems become too complicated and lead to inefficiency. Think about simplicity in your design. It may reduce future headaches.

Maintenance Practices for Optimal Vane Pump Performance

Maintaining vane pumps is crucial for optimal performance. Regular inspections can prevent unexpected failures. Check for signs of wear, such as strange noises or vibration. These indicators often signal that something isn't right.

Fluid cleanliness plays a significant role in the longevity of your pump. Contaminants can lead to efficiency loss. Consider installing filters to protect your vane pump. Change lubricants as needed to ensure smooth operation. Overlubrication, however, can lead to issues too.

Training operators is essential. A knowledgeable team can spot potential problems early. Encourage them to report any irregularities. Documentation of maintenance practices helps track the pump's history. This can lead to better decision-making in repairs or replacements. If overlooked, these aspects can compromise pump reliability. Always be ready to learn from past mistakes.

Top Vane Pump Types for Efficient Fluid Management Solutions

| Vane Pump Type | Flow Rate (L/min) | Pressure Range (bar) | Applications | Maintenance Frequency (Months) |

|---|---|---|---|---|

| Single Vane Pump | 50 | 3-5 | Agricultural, Industrial | 6 |

| Dual Vane Pump | 100 | 5-8 | Pharmaceutical, Food Processing | 12 |

| Rotary Vane Pump | 150 | 2-10 | Chemical Transfer, Fuel Delivery | 8 |

| Variable Displacement Vane Pump | 200 | 5-15 | Hydraulic Systems, Automotive | 24 |

Future Trends in Vane Pump Technology and Efficiency

The future of vane pump technology is evolving rapidly. Innovations focus on enhancing efficiency and adaptability in various applications. Manufacturers are turning to advanced materials. These can withstand extreme temperatures and pressures. Hybrid designs are also emerging. They combine features of traditional vane pumps with modern technologies.

Current trends suggest a shift toward energy-saving solutions. Vane pumps with adjustable displacement offer great potential. They can optimize performance in real-time, based on operational needs. Smart technology integration is increasingly common. Data-driven analysis allows operators to monitor performance closely. This proactive approach can minimize downtime.

Yet, the industry faces challenges. Not all new technologies are proven. Some systems may require more maintenance than expected. Adopting new methods can be a steep learning curve. Companies must weigh the benefits and drawbacks. Continuous improvement is essential for future success.

Related Posts

-

What are the Benefits of Using Rotary Pumps in Various Industries?

-

10 Essential Tips for Choosing the Right Vacuum Oil for Your Equipment

-

Top 5 Vacuum Blowers for Efficient Industrial Applications in 2023

-

Top 10 Benefits of Using Rotary Vane Vacuum Pumps for Your Applications

-

Best Septic Vacuum Pump for Your Needs in 2026?

-

2026 Best Rotary Vane Vacuum Pump Options for Every Need?