- Eng

- Deu

- Fra

2026 Top Vacuum Pump Oil Types for Optimal Performance?

In the evolving landscape of industrial production, the role of vacuum pump oil is critical for maintaining optimal equipment performance. According to a 2023 report by the International Vacuum Technology Association, the global demand for vacuum pump oil grew by 15% over the past year. This data highlights the significance of selecting the right oil type to ensure the longevity of vacuum pumps.

Dr. Emily Carter, a leading expert in vacuum technology, emphasizes the importance of choosing the right oil: “The efficiency of vacuum systems heavily relies on the quality of the vacuum pump oil used.” This insight underscores the necessity for industries to be informed about the various types of vacuum pump oils available. Different applications require specific formulations to prevent mechanical wear and to enhance operational efficiency.

Several factors influence the performance of vacuum pump oil, such as viscosity, thermal stability, and lubrication properties. However, not all oils are created equal. Industries often face challenges in selecting the ideal product that meets their specific needs. Mistakenly opting for the wrong type can lead to increased downtime and operational costs. Understanding the nuances of vacuum pump oil types is crucial for maximizing performance in any vacuum system.

Overview of Vacuum Pump Oils and Their Importance in Performance

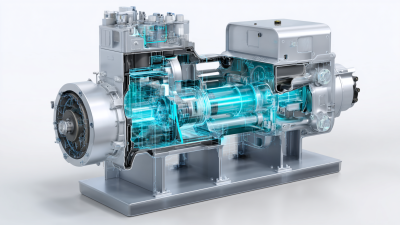

Vacuum pump oils play a critical role in the efficiency and longevity of vacuum pumps. The right oil enhances lubricity and minimizes wear on moving parts. Various oil types exist, including mineral oils, synthetic oils, and bio-based options. Each of these types has distinct properties that affect their performance under specific operating conditions.

Selecting the appropriate vacuum pump oil requires consideration of factors like temperature and application. For instance, some oils perform poorly in extreme temperatures. This can lead to reduced effectiveness and even damage to the pump. Not all oils are compatible with every pump type. Users may find themselves using oils that do not fully meet their needs, which is a common oversight.

Regular maintenance is essential for optimal performance. Changing oils at recommended intervals can prevent buildup and degradation. However, many overlook this basic task. Neglecting proper oil maintenance can result in decreased vacuum levels and increased energy consumption. Ultimately, the choice of vacuum pump oil significantly impacts the overall efficiency of the system. Awareness and careful selection can elevate performance standards.

Types of Vacuum Pump Oils: Mineral, Synthetic, and Biodegradable Options

When choosing vacuum pump oils, three main types stand out: mineral, synthetic, and biodegradable. Each has unique characteristics that impact performance. Mineral oils are traditional choices. They often come from refined petroleum. This option is usually affordable and effective for basic applications. However, mineral oils may not perform well in high temperatures. They can generate more carbon deposits, which might require frequent maintenance.

Synthetic oils offer a different solution. These oils are engineered for specific requirements. They resist thermal degradation and provide better lubrication. Users often report fewer breakdowns with synthetic options. However, they can be more expensive. This might not sit well with every budget decision.

Biodegradable oils have gained attention recently. They are made from renewable resources. This makes them appealing for environmentally conscious applications. However, performance can vary widely among products. Some users find they need more frequent changes. In some instances, this can lead to cost paradoxes. Balancing efficacy and environmental impact remains a challenge. Understanding these options is crucial for optimal pump performance.

Key Properties to Consider When Choosing Vacuum Pump Oil

When choosing vacuum pump oil, consider the viscosity. It affects the oil's ability to perform under different temperatures. A viscosity that is too high can cause excessive wear. Conversely, too low a viscosity may lead to inadequate lubrication. Look for oils that maintain their viscosity over a wide temperature range. This is crucial for optimal pump performance.

Additionally, evaluate the thermal stability of the oil. High-quality oils withstand heat and resist breakdown. Some oils may degrade quickly under extreme conditions. This can cause harmful deposits within the pump. Regular checks on oil condition are advisable. It’s easy to overlook this aspect, yet it plays a vital role in overall pump efficiency.

Lastly, consider the compatibility with materials in your vacuum system. Some oils can react negatively with seals and gaskets. This can lead to leaks and costly repairs. Always consult compatibility guides. The right oil reduces future headaches and maintenance costs. Pay attention to the details; they make a difference in performance.

2026 Top Vacuum Pump Oil Types for Optimal Performance

This chart compares various types of vacuum pump oils based on their viscosity at 40°C and flash point temperature. Choosing the right vacuum pump oil is crucial for optimal performance.

Comparison of Top Vacuum Pump Oil Brands for 2026

When choosing vacuum pump oils for optimal performance, the market offers a wide range of options. Different oils serve distinct needs. For instance, some oils are specially formulated for high-temperature environments. They maintain viscosity even under stress. Others focus on low volatility, minimizing vapor loss during operation. This can greatly affect pump efficiency and lifespan.

A comparison of leading brands reveals varying formulations and additive technologies. Some brands emphasize advanced lubricity. This protects delicate pump components. Others highlight environmental friendliness. They use biodegradable ingredients, reducing ecological impact. However, not all oils perform equally. Some users report that certain products leave residues. This can lead to maintenance challenges.

Evaluating oil performance often requires hands-on testing. The wrong choice may affect the pump's operational efficiency. Not every shop has the correct tools to assess oil quality. Users should actively seek reviews and experiences shared by others. This can guide decisions and prevent costly mistakes. The goal is to maximize the vacuum pump's lifespan with the right oil. As performance characteristics are context-specific, continuous reflection on choices is necessary.

Maintenance Tips for Extending the Life of Your Vacuum Pump Oil

Maintaining vacuum pump oil is crucial for its longevity and performance. Regularly check oil levels. Low oil can lead to pump damage. Replace oil based on the manufacturer’s guidelines. Viscosity changes over time can affect pump efficiency.

Keep the oil clean. Contaminants can harm the vacuum system. Use dedicated filters to prevent impurities. Seal the pump correctly to minimize exposure to dirt. Weekly inspections can help catch any issues early.

Proper storage of oil is also important. Store it in a cool, dry place. Extreme temperatures can alter its properties. However, it’s easy to forget these storage tips. Skipping them can lead to costly pump failures. Always be mindful of your practices. Small actions make a big difference in performance.

Related Posts

-

What is Vacuum Pump Oil? Understanding Its Types, Uses, and Importance in Industrial Applications

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

Understanding the Efficiency and Applications of Rotary Vane Vacuum Pumps in Modern Industries

-

Why Oil Pumps Are Essential for Efficient Fluid Management in Industrial Applications

-

How to Choose the Right Oil Pumps for Your Needs?

-

How to Choose the Right Oil Pumps for Your Needs?