- Eng

- Deu

- Fra

2025 Top Vacuum Oil Types: Key Benefits and Uses You Should Know

In the rapidly evolving industrial landscape, understanding the critical role of vacuum oil is paramount for companies aiming to enhance their operational efficiency. As an essential component in various processes, vacuum oil not only ensures the longevity of equipment but also optimizes performance under high-degree vacuum conditions. Renowned industry expert Dr. Emily Carter emphasizes the significance of this substance, stating, "The right type of vacuum oil can dramatically improve system reliability and reduce maintenance costs."

In 2025, the variety of vacuum oil types available on the market offers unique benefits tailored to diverse applications. From high-temperature operations to specialized processes in laboratories, the right vacuum oil can serve as a game-changer. Understanding these key benefits and their uses is crucial for professionals seeking to make informed decisions that affect performance and efficiency. As we delve into the top types of vacuum oil, we will explore their distinctive characteristics, advantages, and how they integrate into modern industrial applications.

2025 Overview of Vacuum Oil Types and Their Importance

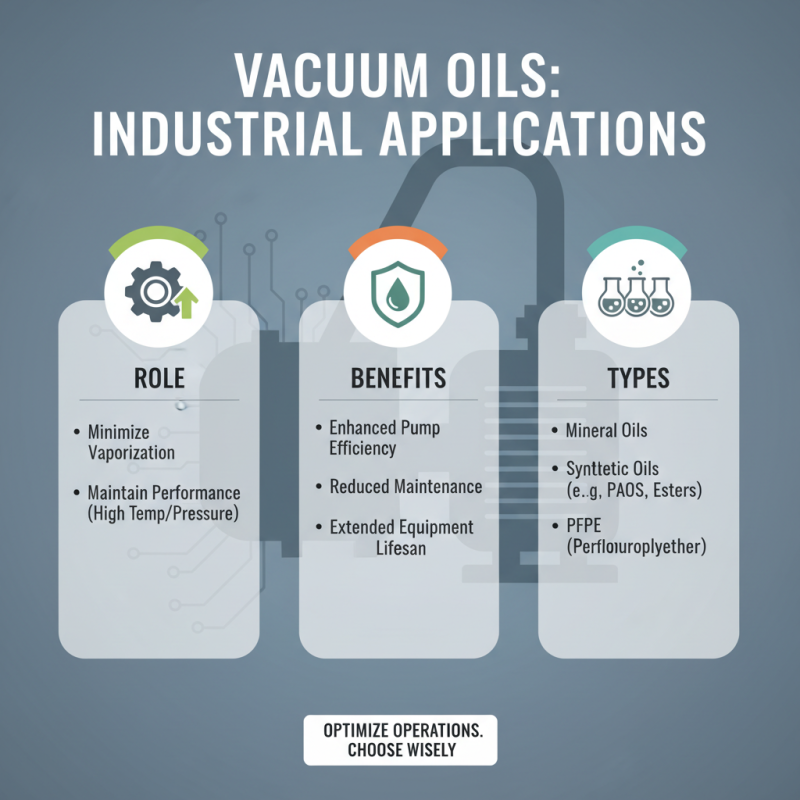

Vacuum oils play a crucial role in various industrial applications, particularly in processes that require a controlled vacuum environment. These specialized oils are designed to minimize vaporization and maintain their performance under high temperatures and pressures. As industries evolve, understanding the different types of vacuum oils available is essential for optimizing operations. The right type of vacuum oil can enhance the efficiency of pumps, reduce maintenance costs, and extend equipment lifespan.

The significance of vacuum oils extends beyond mere lubrication; they also contribute to the overall safety and reliability of industrial operations. By providing consistent performance, these oils help prevent equipment failure and reduce the risk of contamination in sensitive processes. Additionally, selecting the appropriate vacuum oil can significantly impact energy consumption, influencing both operational costs and environmental sustainability. As we explore the landscape of vacuum oils in 2025, it becomes evident that their attributes—such as thermal stability, low vapor pressure, and chemical inertness—are vital for ensuring smooth and efficient industrial processes.

Key Benefits of Vacuum Oils in Industrial Applications

Vacuum oils play a crucial role in various industrial applications due to their unique properties that enhance operational efficiency. These oils are designed to maintain an optimal vacuum environment, which is essential in processes like distillation, evaporation, and drying. One of the key benefits of vacuum oils is their superior thermal stability. They can withstand high temperatures without breaking down, ensuring that the systems operate smoothly and reducing the need for frequent oil changes or maintenance.

Another significant advantage of vacuum oils is their low vapor pressure. This characteristic minimizes the loss of oil and maintains the desired vacuum level over time, preventing contamination within the system. Additionally, vacuum oils exhibit excellent lubrication properties, which decrease friction and wear on mechanical components, contributing to longer equipment life and reduced downtime. Their ability to provide a reliable barrier against moisture also protects the equipment from corrosion, further enhancing system reliability in demanding industrial settings.

Major Types of Vacuum Oils and Their Unique Properties

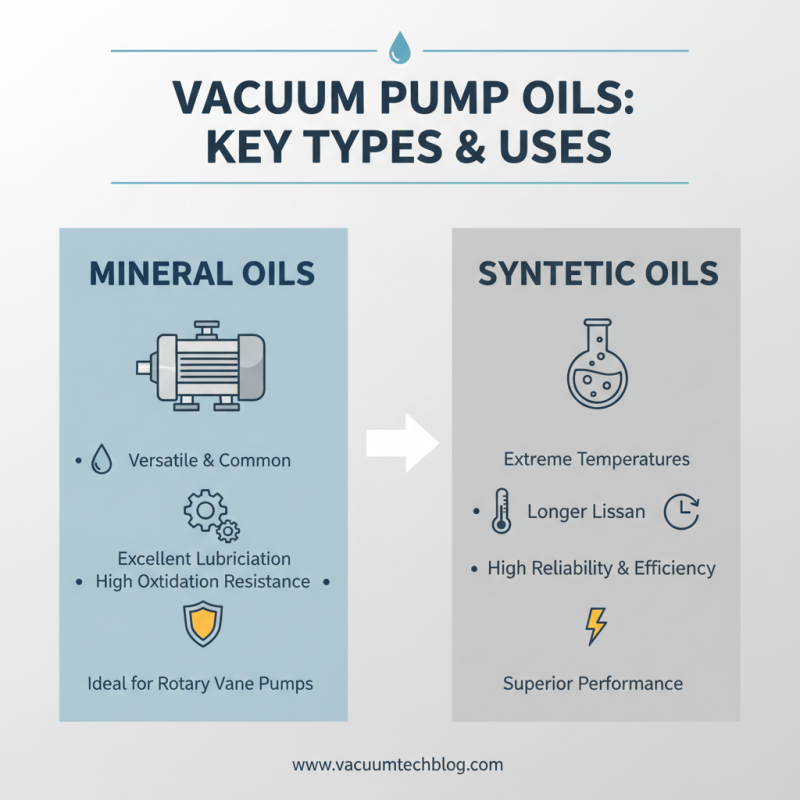

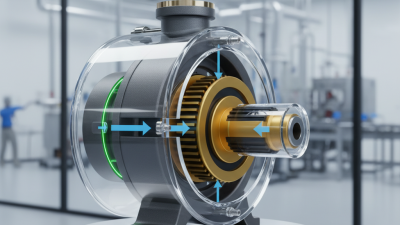

When it comes to vacuum oil, there are several types that stand out due to their unique properties and applications. Mineral oils, for example, are highly versatile and are commonly used in rotary vacuum pumps. These oils provide excellent lubrication and have a high resistance to oxidation, making them ideal for prolonged use. Another notable type is synthetic vacuum oils, which offer superior performance in extreme temperatures and can last significantly longer than their mineral counterparts. These oils are particularly beneficial in applications requiring high reliability and efficiency.

Tips: When selecting a vacuum oil, consider the operating temperature range of your machinery. Using an oil with the appropriate viscosity can significantly enhance performance and extend the lifespan of your equipment.

Additionally, there are special-purpose vacuum oils formulated to meet specific industrial needs. For instance, some oils are designed to minimize foaming or improve energy efficiency, while others may include additives to prevent corrosion. Understanding the specific requirements of your application is crucial for making the right choice, as this can lead to improved operational performance and maintenance savings in the long run.

Tips: Regularly monitor oil condition and replace it as needed to prevent contaminants from damaging your vacuum system. Implementing a routine maintenance schedule can vastly improve the reliability of your equipment.

Common Uses of Vacuum Oils in Various Industries

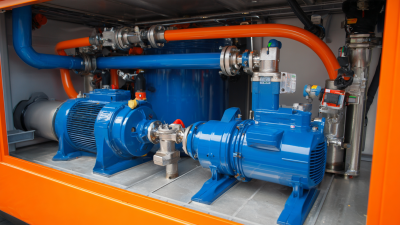

Vacuum oils play a critical role in various industries, facilitating numerous processes that require a stable and efficient performance. In the manufacturing sector, these oils are commonly used in vacuum pumps, which are essential for creating low-pressure environments. This capability is particularly important in industries such as food packaging, pharmaceuticals, and electronics, where maintaining a vacuum can help preserve product integrity and enhance production efficiency. The smooth operation provided by vacuum oils not only minimizes wear and tear on equipment but also optimizes system performance.

In the chemical processing industry, vacuum oils are utilized to improve distillation and extraction processes. By creating a vacuum environment, these oils help to lower boiling points, allowing for more efficient separation of components in complex mixtures. This is especially beneficial in industries dealing with solvents and volatile compounds, where minimizing thermal degradation is crucial. Additionally, vacuum oils are instrumental in various laboratory applications, providing a reliable medium for achieving the necessary vacuum levels required for sensitive experiments and analyses. Their versatility and efficiency make them a critical component in enhancing productivity across multiple sectors.

Future Trends in Vacuum Oil Technology and Sustainability

As the manufacturing and industrial sectors increasingly prioritize efficiency and environmental responsibility, advancements in vacuum oil technology are poised to play a crucial role in promoting sustainability. The shift towards sustainable practices has led to the development of vacuum oils that not only enhance performance but also minimize environmental impact. Innovations such as biodegradable formulations and reduced volatile organic compounds (VOCs) contribute significantly to this transition, ensuring that industries can operate effectively while adhering to stricter environmental regulations.

Future trends in vacuum oil technology are heavily focused on enhancing lubricant longevity and performance. Manufacturers are exploring synthetic and renewable base oils that offer superior thermal stability and oxidation resistance. These advancements allow for longer oil change intervals, reducing waste and the frequency of disposal. Moreover, the incorporation of advanced additives not only improves lubrication efficiency but also helps in reducing equipment wear and energy consumption, thereby contributing to overall sustainability goals. The ongoing research and development in this field promise to deliver vacuum oils that are not only effective but also align with a greener industrial future.

Related Posts

-

Exploring Vacuum Oil: Key Benefits and Industry Trends Influencing Machinery Performance

-

Unlocking the Secrets: How Vacuum Oil Enhances Industrial Efficiency and Equipment Longevity

-

What is Vacuum Oil and How it Benefits Industrial Applications

-

Top 10 Benefits of Using Rotary Vane Vacuum Pumps for Your Applications

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

How to Choose the Right Oil Pumps for Your Industrial Needs