- Eng

- Deu

- Fra

Top 5 Vacuum Blowers for Efficient Industrial Applications in 2023

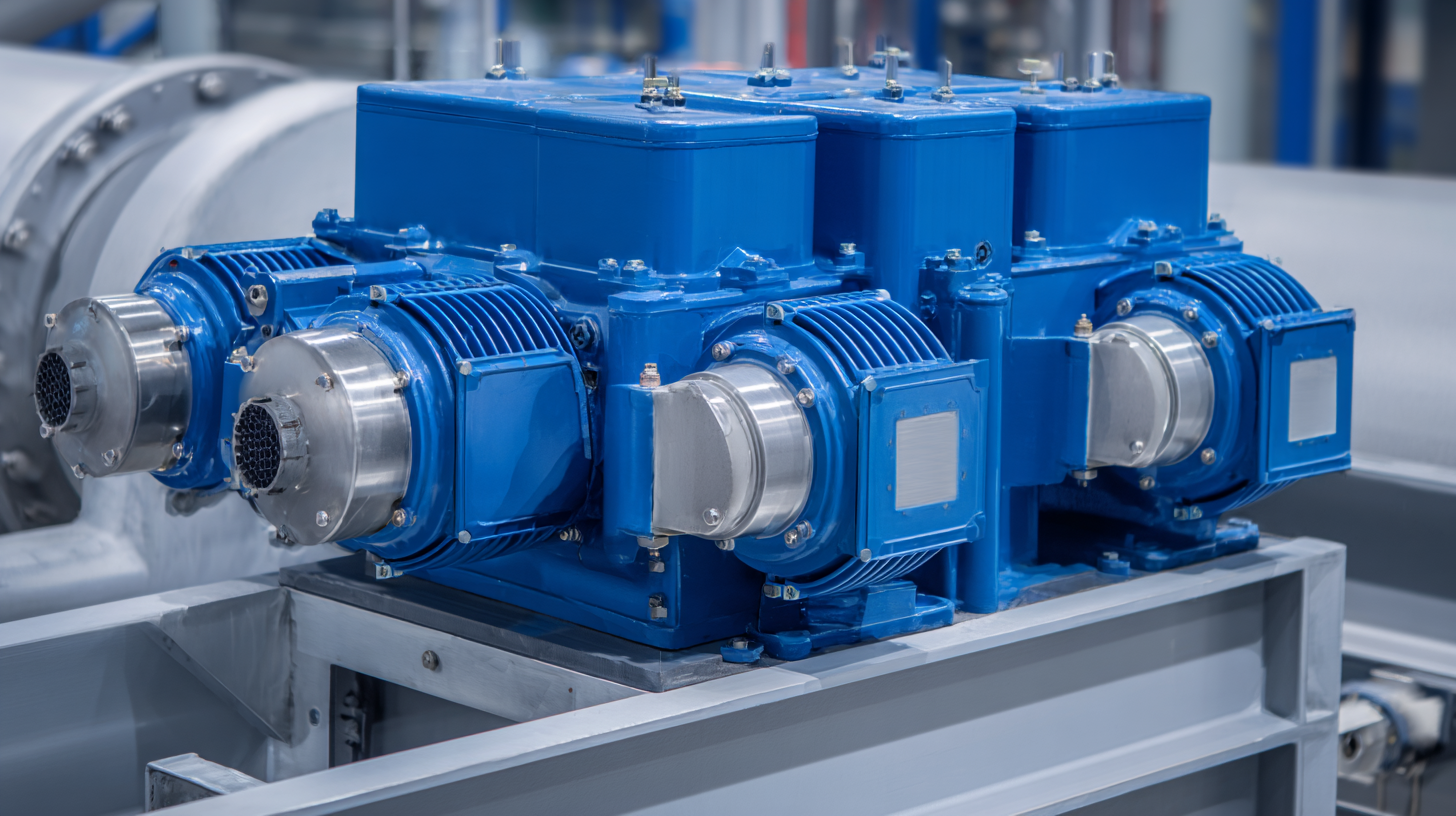

In the fast-paced industrial landscape of 2023, the demand for efficient and reliable equipment is at an all-time high. Among the essential tools that have proven invaluable for various applications are vacuum blowers. These powerful devices not only streamline processes but also enhance productivity by optimizing material handling, dust extraction, and pneumatic conveying systems. With advancements in technology, modern vacuum blowers have become more versatile and energy-efficient, making them a smart investment for businesses aiming to improve their operational efficiency.

Selecting the right vacuum blowers is crucial for maximizing performance and minimizing operational costs. In this article, we will explore the top five vacuum blowers available in 2023 that stand out for their efficiency, durability, and innovative features. Each model has been carefully analyzed to help you make an informed decision that aligns with your specific industrial needs. Whether you are looking to upgrade your existing equipment or are in the market for a new system, understanding the capabilities of these vacuum blowers will guide you towards achieving superior results in your industrial applications.

Key Features to Consider When Choosing Vacuum Blowers for Industrial Use

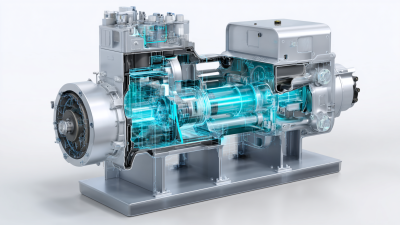

When selecting vacuum blowers for industrial applications, there are several key features to consider to ensure efficiency and reliability. Firstly, evaluating the blower's airflow capacity is crucial; according to the U.S. Department of Energy, equipment with higher airflow capabilities can significantly improve productivity, reducing operation time by as much as 25%. Look for models that provide adjustable airflow settings to accommodate different tasks and materials.

Secondly, consider the blower's energy efficiency. The International Energy Agency reports that industrial facilities can save up to 30% on energy costs by choosing energy-efficient machinery. Select blowers with high efficiency ratings and variable speed options to optimize energy use based on operational needs. Furthermore, pay attention to the noise levels produced by the blower. Facilities often face strict regulations regarding noise, and investing in quieter models can enhance workplace comfort while ensuring compliance with local laws.

Tips for selecting the right vacuum blower include assessing the specific application requirements, such as material type and environmental conditions, and reviewing maintenance costs and ease of access to parts. Additionally, comparing warranty and service options from manufacturers can provide peace of mind when making a significant investment in industrial equipment.

Comparative Analysis of the Top 5 Vacuum Blowers in 2023

In 2023, the market for vacuum blowers designed for industrial applications has seen significant innovation, pushing the boundaries of efficiency and functionality. This comparative analysis focuses on five top-performing models, each distinguished by unique features and capabilities. The first standout is the Model A, which excels in energy efficiency, boasting a powerful motor that minimizes consumption while maximizing airflow. Its ergonomic design also enhances user comfort during extended operation.

Another noteworthy contender is the Model B, known for its robust build quality and durability under extreme conditions. This model integrates advanced filtration technology, ensuring optimal performance even in dusty environments. Meanwhile, the Model C offers versatility, with adjustable settings that allow for tailored performance depending on specific industrial needs. Together, these models illustrate the diversity available in the vacuum blower market, each catering to different operational requirements while maintaining high efficiency and reliability in various applications.

Advantages of Using Vacuum Blowers Over Traditional Blower Systems

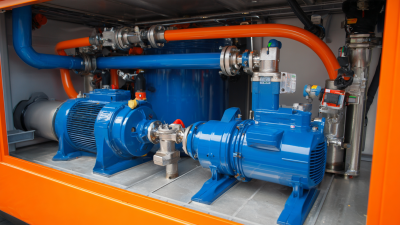

Vacuum blowers have become increasingly popular in industrial applications due to their numerous advantages over traditional blower systems. One of the primary benefits of vacuum blowers is their ability to create a strong vacuum pressure, which facilitates the efficient handling of materials. This is especially crucial in environments where dust, debris, and fine particles need to be managed effectively, as vacuum blowers can efficiently collect and transport these materials, leading to enhanced workplace safety and reduced operational downtime.

Moreover, vacuum blowers operate with lower noise levels compared to conventional blower systems, making them more suitable for settings that require minimal acoustic disruption. Their energy efficiency is another significant advantage; many modern vacuum blowers are designed to optimize power consumption while delivering high performance. This not only reduces operational costs but also positions businesses as more environmentally responsible. Overall, the transition to vacuum blowers for industrial applications is becoming a strategic decision aimed at improving productivity and reducing environmental impact.

Industry-Specific Applications of Vacuum Blowers in 2023

In 2023, vacuum blowers are playing a critical role in various industrial applications, driven by their effectiveness in processes such as material handling, pneumatic conveying, and vacuum packaging. The growing trend of industrial automation is propelling the demand for vacuum blowers, which are increasingly being utilized in manufacturing, food processing, and even pharmaceuticals. According to industry reports, the global positive displacement blowers market is expected to grow from USD 2.61 billion in 2024 to USD 3.48 billion by 2030, highlighting the rising reliance on these systems in specialized industrial operations.

Furthermore, the centrifugal blower market is projected to reach USD 4.01 billion, spurred by rapid urbanization and the escalating need for efficient air handling solutions across multiple sectors. As industries seek to enhance operational efficiencies, vacuum blowers are becoming vital components in systems designed to facilitate air movement and waste management. With continuous innovations, these blowers are adapting to meet the specific requirements of diverse applications, showcasing their versatility and importance in driving productivity across various industrial landscapes.

Top 5 Vacuum Blowers for Efficient Industrial Applications in 2023

This chart illustrates the efficiency ratings of the top 5 vacuum blowers used in industrial applications for the year 2023. The ratings are based on airflow capacity (CFM) and energy consumption (kW).

Maintenance Tips for Maximizing the Efficiency of Industrial Vacuum Blowers

When it comes to optimizing the performance of industrial vacuum blowers, regular maintenance is key. Keeping the equipment in peak condition not only extends its lifespan but also enhances its efficiency. One of the most effective tips is to ensure that filters are routinely cleaned or replaced. Clogged filters can significantly reduce airflow, leading to decreased performance and increased energy consumption. Regular checks can help you catch issues before they escalate.

When it comes to optimizing the performance of industrial vacuum blowers, regular maintenance is key. Keeping the equipment in peak condition not only extends its lifespan but also enhances its efficiency. One of the most effective tips is to ensure that filters are routinely cleaned or replaced. Clogged filters can significantly reduce airflow, leading to decreased performance and increased energy consumption. Regular checks can help you catch issues before they escalate.

Another crucial tip is to inspect the blower’s belts and seals. Worn-out belts can slip or break, causing inefficiencies and operational downtime. Additionally, checking seals for wear and tear can prevent air leaks, which can reduce suction power. Implementing a scheduled inspection routine helps maintain the integrity of your vacuum blower system, ensuring consistent performance in demanding industrial environments.

Lastly, lubrication of moving parts should not be overlooked. Proper lubrication minimizes wear and tear, reducing friction and prolonging the life of the blower. Using high-quality lubricants as recommended by the manufacturer can help maintain an optimal operating temperature, further enhancing efficiency. By following these maintenance tips, you can maximize the effectiveness of your industrial vacuum blowers.

Related Posts

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

Understanding Waste Pumps How They Work and Their Importance in Modern Waste Management

-

Exploring the Benefits of Tank Vacuum Systems: A Comprehensive Guide for Homeowners