- Eng

- Deu

- Fra

Top 10 Vacuum Blower Pumps for Efficient Performance in Various Applications?

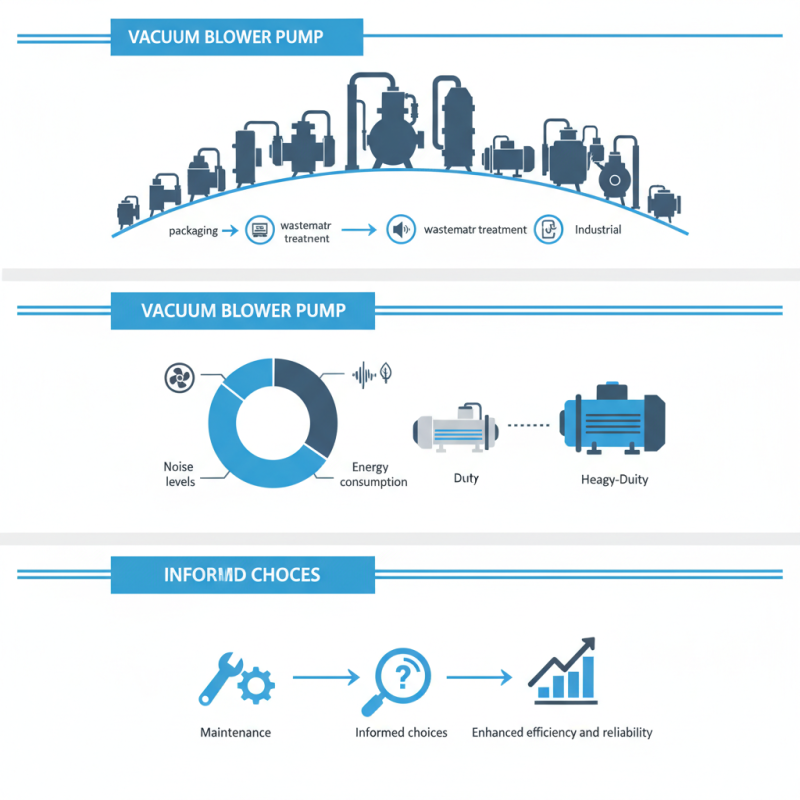

In today's industrial landscape, efficiency is key, particularly when it comes to vacuum blower pumps. These devices play a crucial role in various applications, from packaging to wastewater treatment. According to Dr. Sarah Thompson, an industry expert in vacuum systems, "Choosing the right vacuum blower pump can significantly enhance operational efficiency and reliability."

Effective performance hinges on selecting the appropriate model for specific needs. Factors such as cfm ratings, noise levels, and energy consumption should be considered. Not every vacuum blower pump can excel in every situation. For instance, a pump designed for light-duty tasks may not handle heavier workloads effectively. Understanding the unique requirements of each application is essential.

Despite advancements in technology, challenges remain. Users often underestimate maintenance needs or fail to adjust settings for new tasks. This oversight can lead to inefficiencies. Addressing these concerns will help maximize the potential of vacuum blower pumps. As industries strive for better performance, informed choices become more important than ever.

Understanding Vacuum Blower Pumps: Definition and Functionality

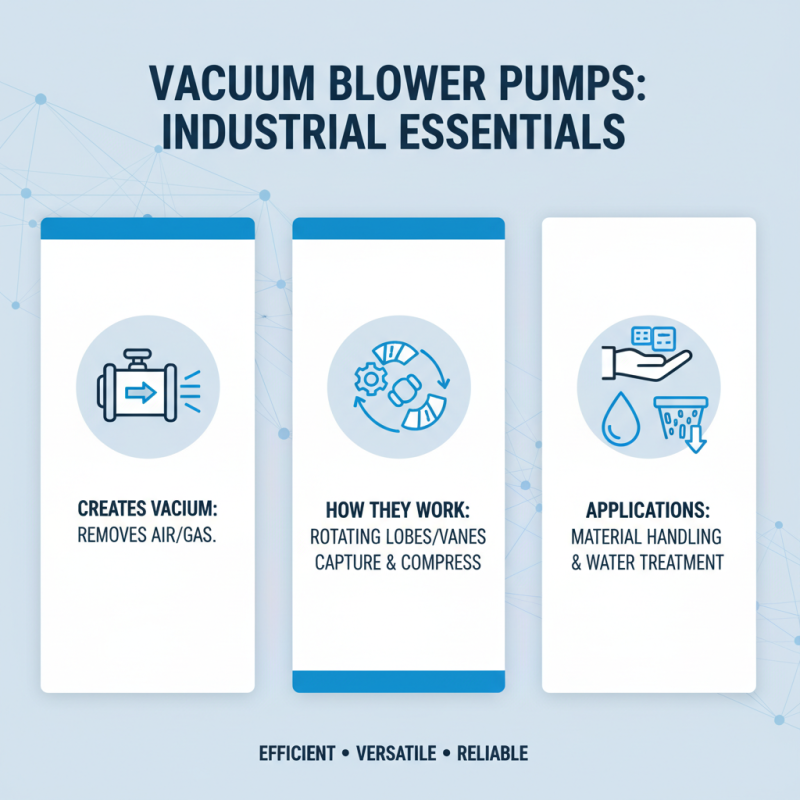

Vacuum blower pumps are essential devices used in various industries. They create a vacuum by removing air or gas from a specific space. This action allows for different applications, from material handling to water treatment. The functionality of these pumps hinges on their design and mechanism. They often feature rotating lobes or vanes that capture and compress air. This process generates a low-pressure zone, facilitating efficient operations.

In practical terms, vacuum blower pumps can aid in dust extraction. They efficiently remove waste particles from environments. They also play a vital role in pneumatic conveying systems. This application ensures that materials are transported smoothly through pipelines. However, their effectiveness can wane if not properly maintained. Clogged filters and worn parts can hinder performance, leading to inefficiencies.

Understanding their operation often requires technical knowledge. Simple troubleshooting can sometimes resolve issues. For instance, checking seals could prevent air leaks, improving efficiency. Users should regularly inspect these devices to ensure optimal function. Neglecting maintenance can lead to larger problems down the line. Therefore, a proactive approach is necessary for their longevity and reliability.

Key Features to Consider When Selecting Vacuum Blower Pumps

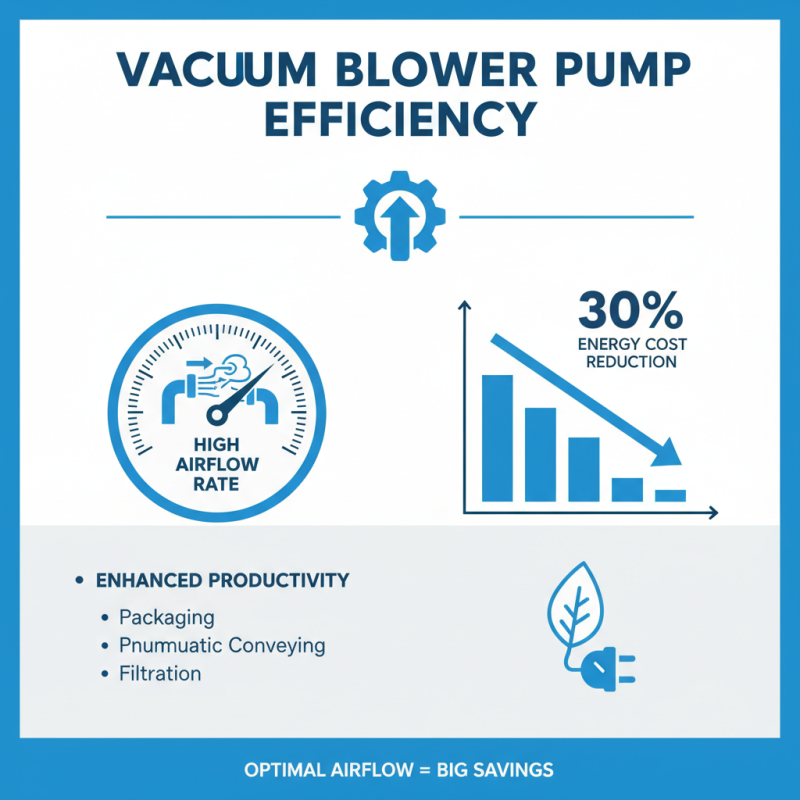

When choosing vacuum blower pumps, efficiency is paramount. Look for pumps that provide a high airflow rate to ensure effective performance. An optimal airflow can significantly enhance the productivity of various applications such as packaging, pneumatic conveying, and filtration processes. According to industry reports, systems that utilize high-efficiency vacuum pumps often see a reduction in energy costs by up to 30%.

Moreover, consider the noise levels of the pump. Some applications may require quieter operation, especially in environments sensitive to sound. For instance, pumps with noise ratings below 70 decibels are ideal for residential or office settings. Durability is also essential. Pumps made from corrosion-resistant materials tend to last longer, even in challenging environments.

However, selecting the right vacuum blower pump is not just about specifications. It is crucial to reflect on the specific needs of the application. A mismatch can lead to inefficiencies and potential downtime. Additional features, like built-in filters and adjustable speed settings, can offer better control. Ultimately, each application may require a unique approach, so thorough research and reflection upon operational needs can lead to better results.

Top 10 Vacuum Blower Pumps for Diverse Applications

Vacuum blower pumps serve a vital role in various industries. They are used in applications such as packaging, food processing, and environmental management. These pumps create a vacuum, which is essential for removing air from a system, thereby enhancing efficiency. According to industry reports, the global market for vacuum pumps is expected to reach a significant value, reflecting their growing importance.

Different applications require varying vacuum levels. For instance, the food industry often uses these pumps to extend shelf life by removing air from packaging. This is crucial for maintaining product quality. In contrast, in environmental industries, these pumps help in waste management by creating a vacuum to transport materials effectively. However, achieving the perfect balance in performance can be a challenge, especially when applications demand high efficiency.

Efficiency ratings for these pumps vary significantly. Some reports suggest that certain models achieve up to 90% efficiency. However, not all pumps meet this standard. Users must carefully evaluate their needs before selecting a pump. The cost of operation also plays a key role in decision-making. High-efficiency models may have higher initial costs but provide savings in energy over time. Nonetheless, understanding each application's unique requirements is essential for optimal use.

Comparison of Performance and Efficiency of Leading Models

When evaluating vacuum blower pumps, performance and efficiency are key factors. Various models boast different specifications that suit specific applications. For instance, a recent industry report indicates that efficient models can achieve operational efficiencies exceeding 90%. This is crucial for industries relying on continuous operation, as downtime may lead to substantial losses.

One notable aspect is the peak airflow rate. Models offering airflow rates upwards of 300 CFM can greatly benefit industrial settings. However, some pumps struggle with noise levels, which can emanate from vibrations or mechanical friction. Noise reduction should also be a focus area in future designs.

Maintenance requirements vary significantly among models. Some designs necessitate more frequent checks, impacting operational uptime. The wear on components can lead to reduced efficiency. In fact, studies suggest that after a year of use, efficiency can decline by 10% if not properly maintained. This highlights the importance of regular servicing. Choosing a pump with an extended maintenance interval could mitigate some of these common concerns.

Top 10 Vacuum Blower Pumps for Efficient Performance in Various Applications

| Model | Max Flow Rate (CFM) | Max Vacuum (inHg) | Power Consumption (W) | Noise Level (dB) | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | 150 | 25 | 500 | 75 | 30 |

| Model B | 200 | 30 | 600 | 80 | 32 |

| Model C | 120 | 20 | 450 | 70 | 28 |

| Model D | 180 | 28 | 550 | 72 | 29 |

| Model E | 160 | 22 | 480 | 68 | 31 |

| Model F | 175 | 26 | 520 | 78 | 33 |

| Model G | 140 | 24 | 460 | 67 | 25 |

| Model H | 210 | 32 | 650 | 85 | 34 |

| Model I | 130 | 21 | 490 | 69 | 27 |

| Model J | 155 | 27 | 550 | 74 | 29 |

Maintenance and Care Tips for Optimal Vacuum Blower Pump Performance

To ensure optimal performance of vacuum blower pumps, regular maintenance is crucial. Begin by checking the pump's oil level frequently. Low oil can cause overheating and damage. Clean the air filters regularly, as dust buildup can hinder airflow. Blocked filters lead to inefficient operation and higher energy costs.

Inspect the pump for any leaks. Seals can wear out over time, allowing air to escape. Monitor the pump’s noise levels, as unusual sounds may indicate mechanical issues. Make adjustments or repairs to prevent further damage. Don't forget to maintain the hoses and connections. Frayed hoses can reduce suction efficiency.

Lastly, keep an eye on operating temperatures. If the pump runs too hot, it may be time to consider replacing components. Many overlook basic check-ups, but it only takes a moment to ensure everything is in top shape. Regular upkeep not only prolongs the life of the pump but also enhances its overall productivity. Reflect on these points during your routine checks.

Top 10 Vacuum Blower Pumps Performance Comparison

Related Posts

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

How to Choose the Right Oil Vacuum Pump for Your Needs in 2025

-

How to Choose the Right Vacuum Blower Pump for Your Needs?

-

2026 Best Rotary Vane Vacuum Pump Options for Every Need?

-

The Essential Guide to Understanding Oil Vacuum Pumps and Their Applications in Industry