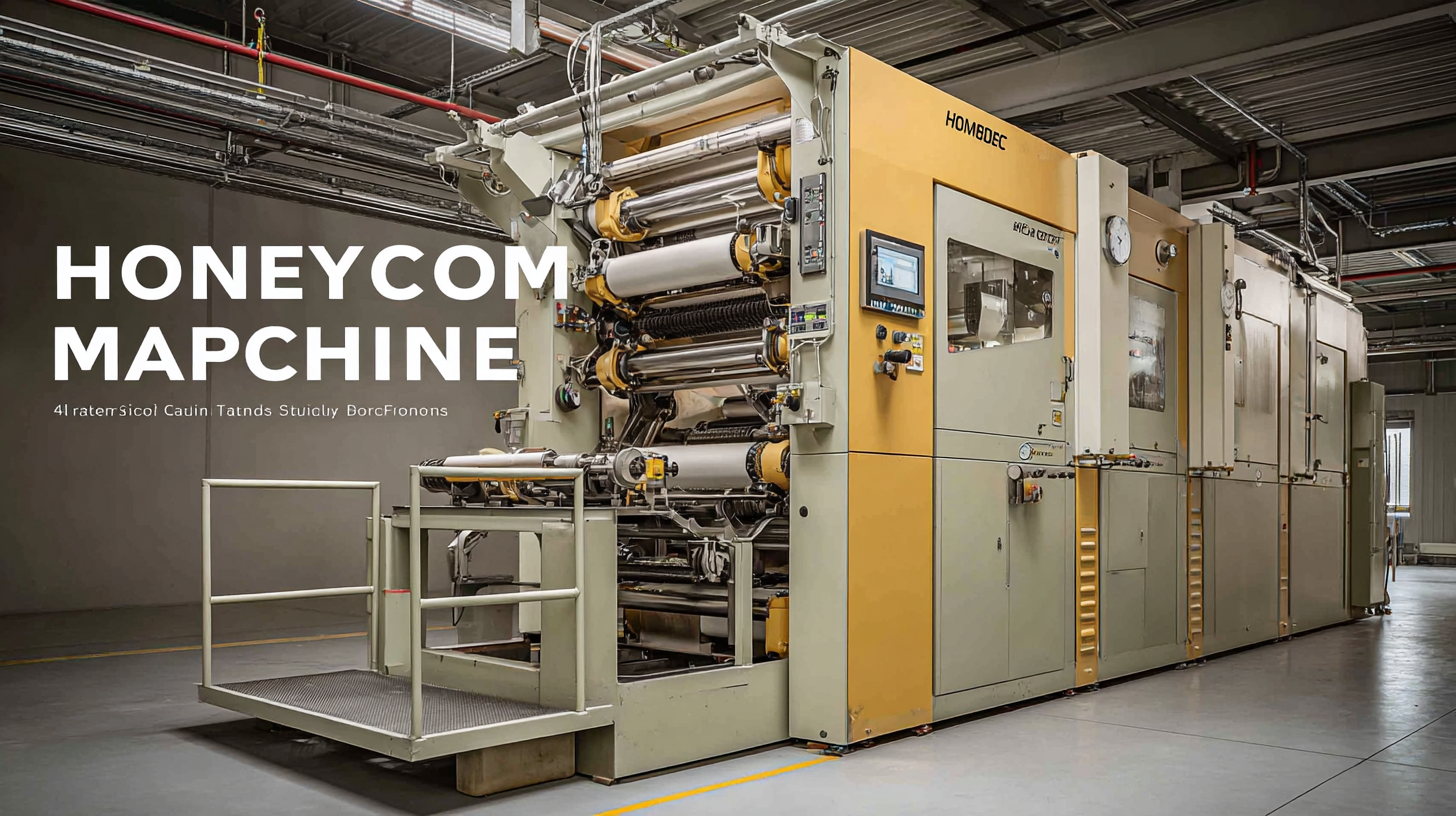

Top Industry Standards and 5 Compelling Reasons to Choose the Best Honeycomb Paper Machine

In recent years, the demand for innovative packaging solutions has surged, with the global protective packaging market expected to reach $60.55 billion by 2026, according to industry reports. This escalating need has propelled the honeycomb paper industry forward, showcasing the versatility and environmental benefits of the Honeycomb Paper Machine. The machine not only caters to the increasing demand for lightweight yet sturdy packaging options but also aligns with sustainable practices by utilizing renewable resources. As countries worldwide strive to reduce plastic usage, honeycomb paper has emerged as a favored alternative, primarily due to its recyclable nature and strong protective qualities.

Furthermore, China’s manufacturing sector has established itself as a leader in this domain, exporting advanced Honeycomb Paper Machines to multiple countries, enabling businesses to enhance their packaging efficiency while contributing to global sustainability efforts.

Emerging Technologies Shaping Honeycomb Paper Machine Standards in 2025

As we look ahead to 2025, emerging technologies are set to revolutionize the standards of honeycomb paper machines, making them more efficient and sustainable than ever. One significant advancement lies in the integration of artificial intelligence and machine learning. These technologies enable real-time monitoring and predictive maintenance, drastically reducing downtime and ensuring optimal machine performance. Moreover, AI can enhance production efficiency by analyzing data and suggesting adjustments to improve quality and reduce waste.

In addition to AI, the adoption of eco-friendly materials and processes is becoming a focus in the industry. Innovations such as bio-based adhesives and recyclable paper components align with the growing demand for sustainability in manufacturing. This transition not only minimizes environmental impact but also meets the expectations of eco-conscious consumers. As companies embrace these advancements, they will not only enhance the functionality of honeycomb paper machines but also contribute positively to the global move towards sustainability in industrial processes.

Top Industry Standards and 5 Compelling Reasons to Choose the Best Honeycomb Paper Machine

| Standard | Description | Impact on Quality | Technology Trends |

|---|---|---|---|

| ISO 9001 | Quality Management Systems | Ensures consistent quality in production | Adoption of automated quality checks |

| FSC Certification | Forest Stewardship Council certification | Encourages sustainable sourcing of materials | Shift towards eco-friendly production |

| CE Marking | Conformité Européenne marking for safety | Ensures safety and health compliance | Incorporation of smart technologies |

| ASTM D4727 | Standard Specification for Honeycomb Core Materials | Defines performance standards for honeycomb structures | Development of lightweight, strong materials |

| ISO 14001 | Environmental Management Systems | Reduces environmental impact of manufacturing | Increased focus on sustainability practices |

Key Benefits of Investing in Advanced Honeycomb Paper Machinery

Investing in advanced honeycomb paper machinery brings numerous key benefits that can significantly enhance the efficiency and productivity of manufacturing processes. According to a report by Smithers Pira, the global demand for sustainable packaging solutions, including honeycomb paper products, is projected to reach $400 billion by 2024. This surge in demand highlights the necessity for manufacturers to adopt cutting-edge technology that can optimize production while maintaining high quality.

One major advantage of advanced honeycomb paper machinery is the improvement in operational efficiency it offers. Modern machines are designed to operate at higher speeds with reduced downtime, facilitating increased output without compromising on quality. A study conducted by industry experts noted that upgrading to advanced machinery can enhance production efficiency by as much as 30%. Furthermore, the implementation of automated systems in these machines allows for better precision in cutting and shaping, resulting in less waste and a more environmentally friendly manufacturing process. As companies seek to align with sustainability goals, investing in such machinery becomes not only beneficial but essential for staying competitive in an evolving market.

Sustainability Trends Influencing Honeycomb Paper Production Practices

In today's eco-conscious market, sustainability trends are significantly shaping honeycomb paper production practices. Manufacturers are increasingly prioritizing the use of recycled materials and sustainable sourcing to minimize their environmental footprint. This shift not only adheres to industry standards but also appeals to consumers who are more inclined to support brands that demonstrate environmental responsibility. By investing in high-quality, sustainable honeycomb paper machines, businesses can produce eco-friendly packaging solutions that satisfy market demand while contributing to a greener planet.

When considering improvements to your honeycomb paper production process, focus on optimizing energy efficiency in your machinery. Upgrading to modern machines equipped with energy-saving technologies can lead to significant operational cost reductions. Additionally, implementing waste reduction strategies, such as recycling production scraps, can not only lower costs but also enhance overall sustainability.

Lastly, prioritize transparency in your supply chain. Consumers today are more informed and likely to support companies that openly communicate their sourcing practices. By partnering with certified suppliers and showcasing your commitment to sustainable practices, you can differentiate your business in a competitive market while nurturing consumer trust and loyalty.

Comparative Analysis: Traditional vs. Innovative Honeycomb Paper Machines

When considering the evolution of honeycomb paper machines, a comparative analysis between traditional and innovative models reveals significant differences in performance and efficiency. Traditional honeycomb paper machines, while effective, often operate at slower speeds and require more manual input during production. They rely on dated technology, which can lead to inconsistencies in product quality and increased waste. The labor-intensive nature of these machines can also drive up operational costs, making them less appealing for modern manufacturers looking to optimize their workflows.

In contrast, innovative honeycomb paper machines harness advanced technologies such as automation and real-time monitoring. These machines not only streamline production processes but also enhance precision and reduce material waste. By employing smart technology, manufacturers can achieve higher output rates, minimize downtime, and ensure consistent quality in their products. Moreover, the integration of eco-friendly materials in newer machines reflects a growing commitment to sustainability—an essential consideration in today’s eco-conscious market. As businesses strive to remain competitive, the shift towards innovative honeycomb paper solutions becomes increasingly compelling.

Future Market Opportunities for Honeycomb Paper Manufacturing Solutions

The honeycomb paper manufacturing industry is poised for significant growth as sustainability becomes a key focus across various sectors. With environmental concerns increasingly influencing businesses, honeycomb paper offers a renewable and biodegradable alternative to traditional packaging materials. This transition opens up numerous market opportunities for manufacturers to innovate and meet the demand for eco-friendly solutions.

Investment in advanced honeycomb paper machines presents a strong business case for companies aiming to capitalize on this market potential. These machines not only streamline production processes but also enhance the quality and durability of honeycomb products. As more industries, from e-commerce to construction, seek reliable and sustainable packaging options, manufacturers equipped with cutting-edge technology will be well-positioned to lead the market. Exploring these future opportunities can yield substantial returns, reflecting the growing commitment to sustainability in manufacturing practices.