- Eng

- Deu

- Fra

Why Choose a Rotary Vane Vacuum Pump for Your Industrial Applications

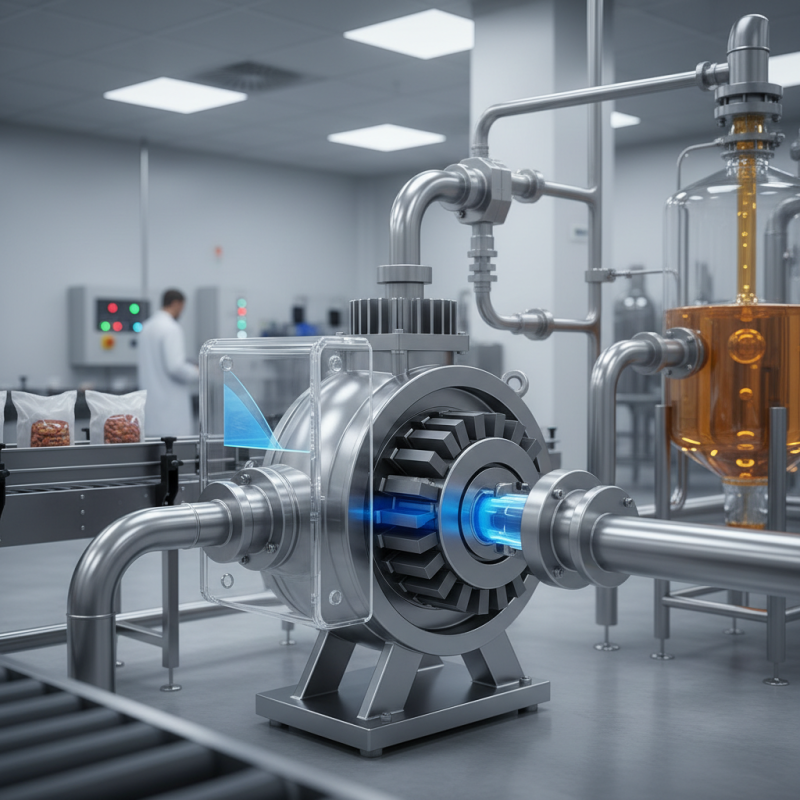

In the realm of industrial applications, the choice of vacuum pumping technology can significantly impact efficiency, performance, and overall operational costs. One such technology that stands out is the rotary vane vacuum pump. As John Smith, an industry expert with over two decades of experience in vacuum systems, aptly stated, "The rotary vane vacuum pump combines reliability and versatility, making it a preferred choice for numerous industrial tasks." This statement encapsulates the essence of why many industries are gravitating towards this pump type.

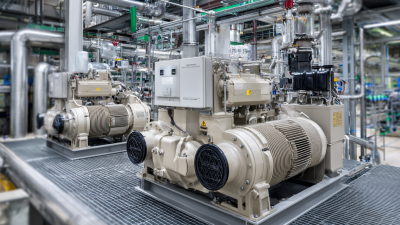

Rotary vane vacuum pumps are renowned for their robust design and ability to provide consistent vacuum levels across a variety of applications, from food packaging to chemical processing. Their operational efficiency not only enhances productivity but also reduces energy consumption, making them an environmentally friendly option. Furthermore, these pumps are designed for easy maintenance, allowing businesses to minimize downtime and maximize their production capabilities.

As industries continue to evolve and demand higher performance from their equipment, selecting a rotary vane vacuum pump can lead to substantial benefits. The blend of efficiency, durability, and simplicity positions these pumps as a top contender in the vacuum technology landscape, catering to the diverse needs of modern industrial applications.

Benefits of Using Rotary Vane Vacuum Pumps in Industry

Rotary vane vacuum pumps have become increasingly popular in various industrial applications due to their unique features and benefits. One of the primary advantages of using rotary vane vacuum pumps is their ability to maintain consistent vacuum levels over an extended period, making them ideal for processes that require stable conditions. According to a report from the Vacuum Industry Association, approximately 40% of industrial vacuum applications utilize rotary vane technology, highlighting its effectiveness in sectors such as packaging, chemical processing, and pharmaceuticals.

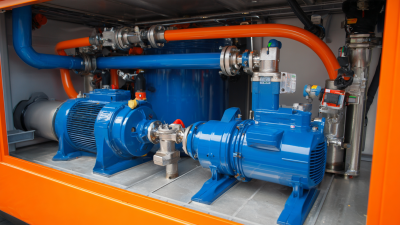

Furthermore, rotary vane vacuum pumps are known for their efficiency and reliability. They typically provide a high pumping speed and can handle a wide range of gases and vapors, which significantly reduces downtime. A study conducted by the International Journal of Vacuum Science indicates that these pumps can operate effectively in environments with varying pressures without sacrificing performance. For industries focused on productivity, this consistency translates to higher output and lower operational costs.

Tips: When selecting a rotary vane vacuum pump, consider factors such as the specific application requirements, the desired vacuum level, and maintenance needs to ensure optimal performance. Regular maintenance, including oil changes and filter replacements, can extend the life of the pump significantly.

Key Features of Rotary Vane Vacuum Pumps for Industrial Use

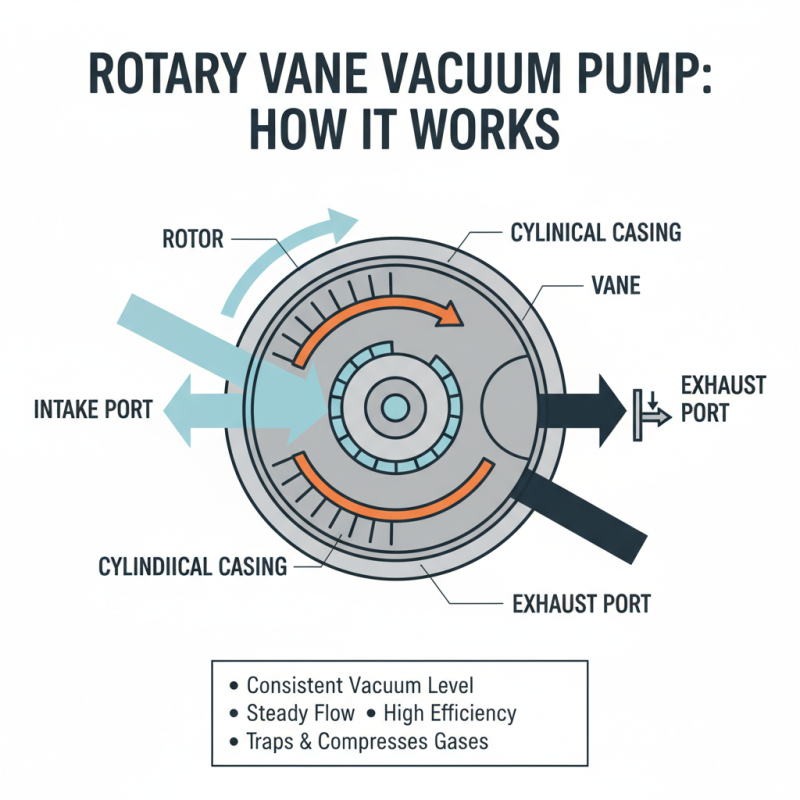

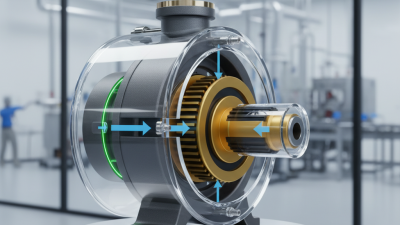

Rotary vane vacuum pumps are highly regarded in various industrial applications due to their unique operational characteristics and efficiency. One of their key features is the ability to maintain a continuous vacuum, which is crucial for processes that require stable conditions. They operate on a principle that utilizes rotating vanes within a cylindrical housing, effectively compressing and creating a vacuum in the chamber. This design allows for consistent performance, even in demanding environments where other pump types might struggle.

Another notable feature of rotary vane vacuum pumps is their minimal maintenance requirements. Unlike some vacuum technologies, these pumps have fewer moving parts, which reduces wear and tear over time. This design results in longer service intervals and lower operational costs, making them an economical choice for industrial facilities. Additionally, their ability to handle both liquids and gases broadens their applicability across various sectors, including food processing, pharmaceuticals, and manufacturing, where versatility is often required. Thus, rotary vane vacuum pumps stand out as efficient and reliable equipment suitable for a myriad of industrial needs.

Key Features of Rotary Vane Vacuum Pumps for Industrial Use

Comparing Rotary Vane Vacuum Pumps with Other Pump Types

When evaluating vacuum pump options for industrial applications, it’s essential to compare rotary vane vacuum pumps with other types of pumps. Rotary vane vacuum pumps operate by utilizing a series of vanes mounted on a rotor that spins within a cylindrical casing. As the rotor turns, the vanes extend and retract, creating specific volumes that trap and compress the air or gas, efficiently removing it from the system. This design results in a consistent level of vacuum and is particularly suited for applications that require a steady flow and high efficiency.

In contrast, other vacuum pump types, such as diaphragm pumps and rotary scroll pumps, utilize different mechanisms. Diaphragm pumps are known for their chemical resistance and are suitable for handling corrosive materials, but they typically produce lower vacuum levels. Rotary scroll pumps, while also effective in creating a vacuum, can be more complex in their construction and maintenance. The operational characteristics of rotary vane pumps, such as their robustness and ability to handle varying gas compositions, often make them the preferred choice for industries that demand reliability and performance. This comparison highlights the unique advantages of rotary vane vacuum pumps in maintaining optimal vacuum conditions across diverse industrial applications.

Applications of Rotary Vane Vacuum Pumps in Various Industries

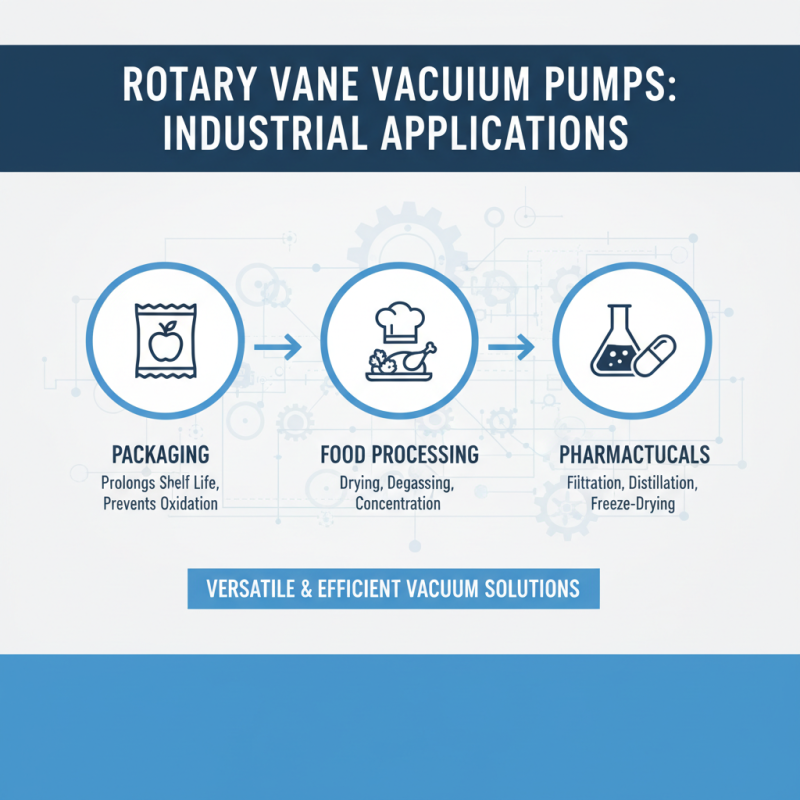

Rotary vane vacuum pumps are integral to many industrial applications due to their versatility and efficiency. These pumps are widely used in industries such as packaging, food processing, and pharmaceuticals. In packaging, for instance, they help create vacuum environments that prolong shelf life by preventing oxidation and microbial growth. The controlled vacuum levels allow for precise packaging processes, ensuring that products remain fresh for a more extended period.

In the food processing industry, rotary vane vacuum pumps are employed in the vacuum sealing of products, which not only enhances hygiene but also reduces spoilage. Additionally, in pharmaceutical manufacturing, these pumps create sterile environments necessary for producing medications and maintaining the integrity of active ingredients. The pumps provide a consistent and reliable vacuum, crucial for various stages of production, from drying to the filtration of sensitive compounds.

**Tips:** When selecting a rotary vane vacuum pump for your application, consider the pump's capacity and the specific vacuum level required. Regular maintenance is also essential to ensure optimal performance and longevity of the pump. Additionally, ensuring compatibility with the materials being processed can prevent contamination and enhance overall operational efficiency.

Maintenance and Performance Tips for Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps are known for their reliability and efficiency in various industrial applications. To ensure optimal performance, regular maintenance is crucial. Users should adhere to a consistent schedule for oil changes, as the lubricant plays a vital role in reducing friction and wear on the internal components. Over time, the oil can become contaminated, which may lead to increased operating temperatures and reduced efficiency. Additionally, checking and replacing filters regularly helps maintain a clean and efficient system, preventing particles from entering the pump mechanism.

Another key aspect of maintaining rotary vane vacuum pumps is monitoring operating parameters such as pressure and temperature. Deviations from standard operating conditions can indicate underlying issues that require immediate attention. Keeping an eye on these metrics not only helps in preventing breakdowns but also extends the lifespan of the equipment. It is also advisable to maintain the ambient conditions around the pump, ensuring proper ventilation and temperature control to promote optimal performance. By following these maintenance tips, industries can maximize the efficiency and longevity of their rotary vane vacuum pumps.

Why Choose a Rotary Vane Vacuum Pump for Your Industrial Applications - Maintenance and Performance Tips for Rotary Vane Vacuum Pumps

| Aspect | Details |

|---|---|

| Pump Type | Rotary Vane |

| Common Industries | Food Packaging, Medical Equipment, Electronics |

| Operating Pressure Range | 0.5 to 1000 mbar |

| Maintenance Frequency | Every 3 to 6 months |

| Common Issues | Vane Wear, Oil Leakage, Noise |

| Performance Tip | Regularly check oil levels and replace worn vanes. |

| Average Lifespan | 5 to 10 years with proper maintenance |

Related Posts

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

-

2025 Top 5 Vacuum Blower Pumps to Boost Your Industrial Efficiency

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

What is an Oil Vacuum Pump and How Does it Work for Efficient Operations

-

Top 10 Benefits of Using Rotary Vane Vacuum Pumps for Your Applications