- Eng

- Deu

- Fra

What is an Oil Vacuum Pump and How Does it Work for Efficient Operations

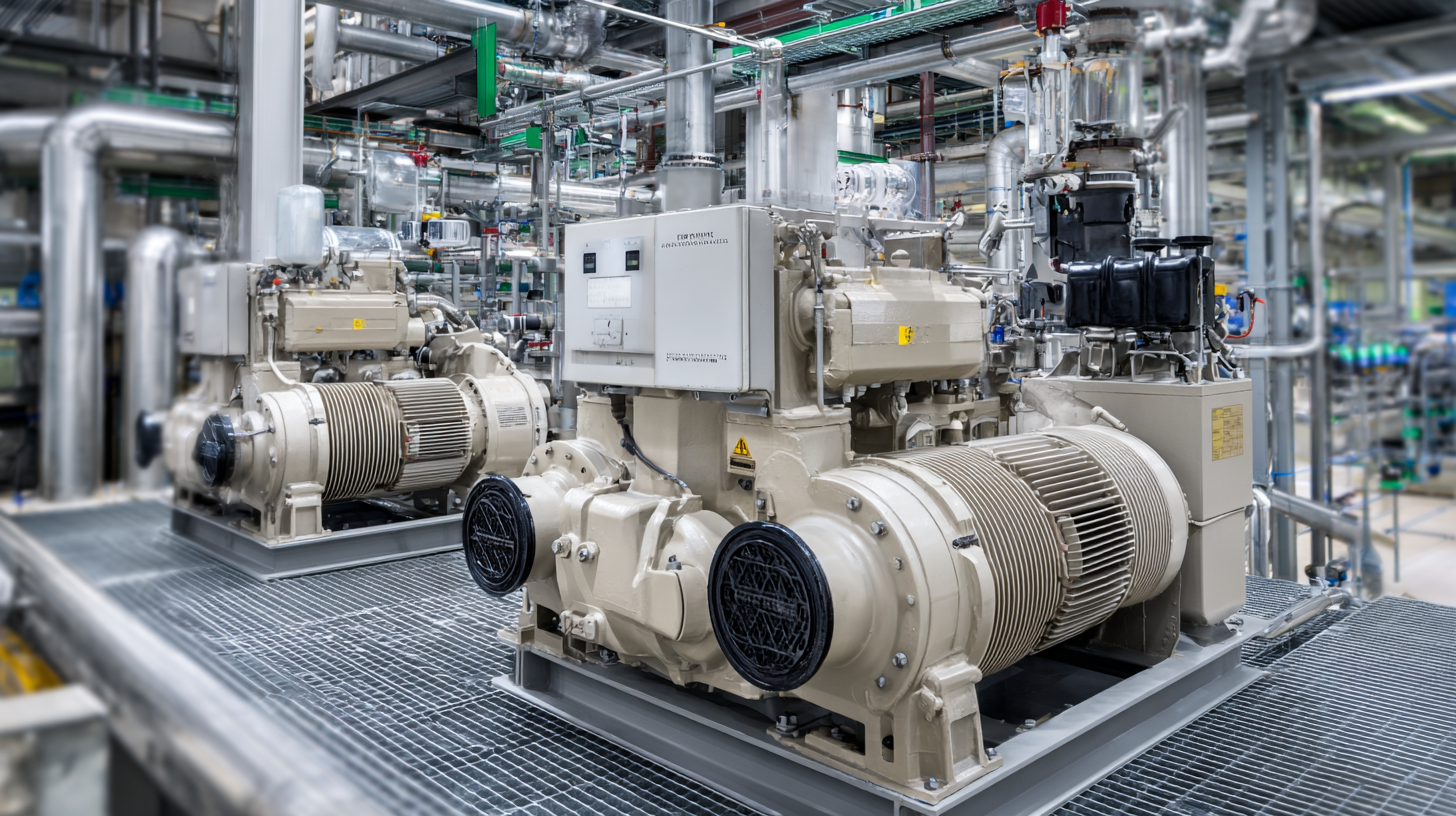

The demand for oil vacuum pumps has surged in various industrial applications, driven by the need for efficient operation and reliable performance in managing vacuum environments. According to the Global Vacuum Pump Market report by ResearchAndMarkets, the vacuum pump market is projected to witness a significant growth rate, reflecting an increasing adoption of oil vacuum pumps across sectors such as chemical processing, food production, and pharmaceuticals. These pumps are renowned for their ability to create deep vacuum conditions, vital for tasks ranging from solvent extraction to equipment maintenance.

Oil vacuum pumps are specifically designed to provide a high level of performance and efficiency, utilizing oil to not only lubricate internal components but also to aid in the sealing process. This functionality is essential for maintaining an optimal vacuum environment and ensuring equipment longevity. With the rising emphasis on energy efficiency and reduced operational costs, industries are increasingly turning to oil vacuum pumps as a reliable solution to enhance their production capabilities. Industry analysis indicates that advancements in technology and pumps' operational efficiency could lead to a notable reduction in energy consumption, further solidifying their role in modern industrial applications.

Understanding the Functionality of Oil Vacuum Pumps in Industrial Applications

Oil vacuum pumps play a crucial role in various industrial applications by creating a vacuum that enhances operational efficiency. These pumps operate by utilizing an oil-based lubrication system that not only lubricates moving parts but also aids in sealing, thereby improving overall performance. As the pump operates, it removes air and other gases from a designated space, resulting in a vacuum that is essential for processes such as distillation, evaporation, and drying. This ability to maintain a consistent vacuum is vital in sectors like pharmaceuticals, food processing, and chemical manufacturing, where precise environmental control is necessary.

In practical terms, the functionality of oil vacuum pumps is exemplified in applications like packaging and vacuum forming. In packaging, they help remove air from containers, extending shelf life and preserving product integrity. Similarly, in vacuum forming, these pumps create the necessary vacuum to shape plastics into desired forms while ensuring precision and reducing material waste. By combining efficient removal of air with effective sealing, oil vacuum pumps serve as indispensable tools in maximizing productivity and quality in industrial processes.

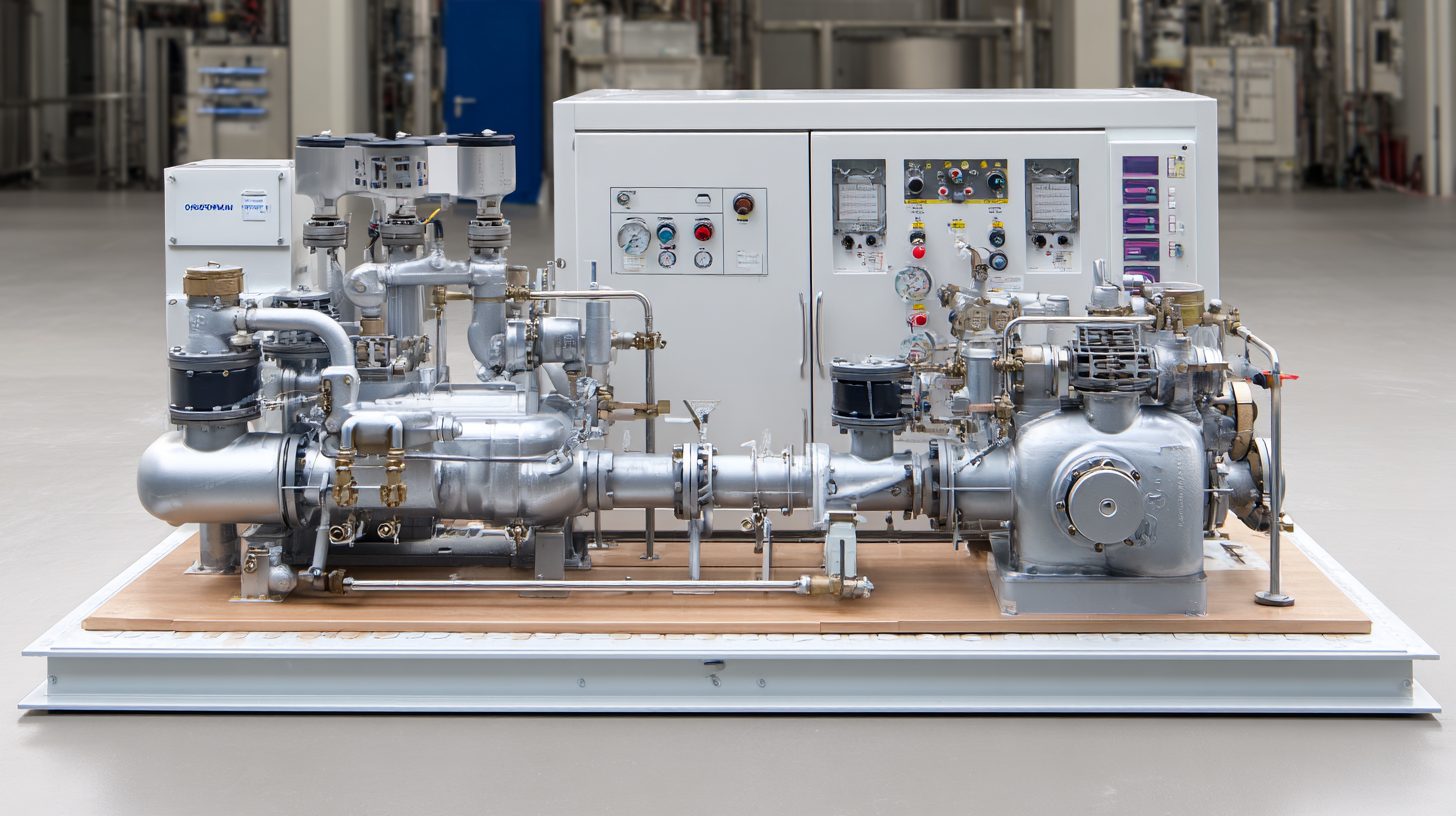

Key Components and Mechanisms of Oil Vacuum Pumps for Optimal Performance

Oil vacuum pumps are essential for various industrial processes, utilizing a combination of key components to achieve optimal performance. At the heart of these pumps is the rotor, which facilitates the movement of air and gases by creating a vacuum. The rotor's interaction with the chamber walls minimizes turbulence, ensuring a smooth flow. A study by the American Vacuum Society highlights that efficient rotor design can improve vacuum levels by up to 30%, demonstrating the importance of precise engineering in these systems.

Oil vacuum pumps are essential for various industrial processes, utilizing a combination of key components to achieve optimal performance. At the heart of these pumps is the rotor, which facilitates the movement of air and gases by creating a vacuum. The rotor's interaction with the chamber walls minimizes turbulence, ensuring a smooth flow. A study by the American Vacuum Society highlights that efficient rotor design can improve vacuum levels by up to 30%, demonstrating the importance of precise engineering in these systems.

Another critical component is the oil mist eliminator, which works to separate oil from the air being exhausted. Advanced models, such as those designed by Becker and Busch, incorporate multi-stage filters that can achieve separation efficiencies exceeding 99%. This is particularly significant in sectors like food processing and pharmaceuticals, where contamination control is paramount. Furthermore, regular maintenance of these components is crucial, as neglected pumps can lose up to 20% of their efficiency due to wear and tear, as reported by the Society of Vacuum Coaters. By understanding these mechanisms and maintaining optimal conditions, industries can enhance their operational efficiency while reducing environmental impacts.

Industry Standards and Specifications: Measuring Oil Vacuum Pump Efficiency

Oil vacuum pumps are critical tools in various industrial applications, serving to create a vacuum by removing air and other gases from a closed system. Efficiency in these pumps is essential for optimal performance, which is where industry standards and specifications come into play. These benchmarks guide manufacturers and users in evaluating the capability and reliability of oil vacuum pumps, ensuring that they meet the required operational performance necessary for different applications.

One of the key specifications in measuring oil vacuum pump efficiency is the ultimate vacuum level, which indicates how much gas the pump can remove under optimal conditions. Additionally, the pump's pumping speed, often measured in cubic feet per minute (CFM) or liters per minute (L/min), reflects its ability to eliminate gas from the system quickly. Other important factors include energy consumption and maintenance requirements, as energy-efficient pumps not only lower operational costs but also reduce environmental impact. By adhering to industry standards, operators can maintain their equipment's performance and longevity, ultimately leading to improved productivity and minimized downtime in their operations.

Comparative Analysis of Oil Vacuum Pumps vs. Other Vacuum Technologies

When comparing oil vacuum pumps to other vacuum technologies, it's essential to recognize the unique advantages they offer for various industrial applications. Oil vacuum pumps are designed to create a deep vacuum level, which makes them suitable for processes requiring high precision and efficiency, such as in the manufacturing of semiconductors or the food packaging industry. Their ability to reach lower pressures allows for the efficient removal of gases and vapors, ensuring product integrity and preventing contamination.

In contrast, other vacuum technologies, such as diaphragmatic or dry pumps, tend to have limitations when it comes to achieving similar vacuum levels. While they may be more environmentally friendly and easier to maintain, their throughput and ultimate vacuum performance often fall short in critical applications. Additionally, oil vacuum pumps can handle larger volumes of gases, making them more versatile for industries that require extensive vacuum operations. However, the choice between oil vacuum pumps and alternative technologies ultimately depends on the specific operational needs, budget constraints, and environmental considerations of the application at hand.

What is an Oil Vacuum Pump and How Does it Work for Efficient Operations - Comparative Analysis of Oil Vacuum Pumps vs. Other Vacuum Technologies

| Technology Type | Efficiency (%) | Typical Applications | Maintenance Requirement | Cost (USD) |

|---|---|---|---|---|

| Oil Vacuum Pump | 85-95% | Industrial Processes, Packaging | Moderate | 2000-5000 |

| Rotary Vane Pump | 70-90% | Medical Equipment, Lab Work | Low | 1500-4000 |

| Diaphragm Pump | 60-80% | Laboratories, Food Industry | Very Low | 1000-3000 |

| Scroll Pump | 75-95% | Semiconductor, Industrial Coating | Moderate | 3000-7000 |

| Turbomolecular Pump | 90-99% | High Vacuum Applications, Research | High | 5000-15000 |

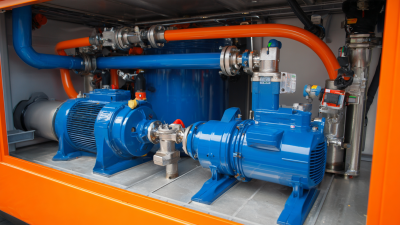

Real-World Applications and Benefits of Using Oil Vacuum Pumps in Manufacturing

Oil vacuum pumps are essential in various manufacturing processes, providing a reliable method to create vacuums for applications like degassing, drying, and packaging. Their ability to efficiently remove air and moisture from products enhances quality control and operational effectiveness. According to a report by the Global Vacuum Pump Market Analysis, the demand for oil vacuum pumps is projected to grow significantly, driven by advancements in manufacturing technologies and increasing automation.

In industries such as food processing and pharmaceuticals, oil vacuum pumps play a crucial role in maintaining product integrity. They help in prolonging shelf life by preventing oxidation and contamination, which can be detrimental to sensitive products. Furthermore, these pumps contribute to energy efficiency; a study by the International Energy Agency highlighted that implementing advanced vacuum technology can reduce energy consumption by up to 30% in manufacturing environments.

Tips: When choosing an oil vacuum pump, assess the specific requirements of your application, such as the required vacuum level and flow rate. Regular maintenance, including oil changes, is essential for optimal performance and longevity of the pump. Also, consider integrating variable frequency drives (VFDs) to optimize energy use further and enhance operational flexibility.

Related Posts

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

Exploring the Benefits of Tank Vacuum Systems: A Comprehensive Guide for Homeowners

-

Understanding Waste Pumps How They Work and Their Importance in Modern Waste Management

-

Maximizing Efficiency: The Impact of Industrial Vacuum Blowers on Energy Consumption in Manufacturing