- Eng

- Deu

- Fra

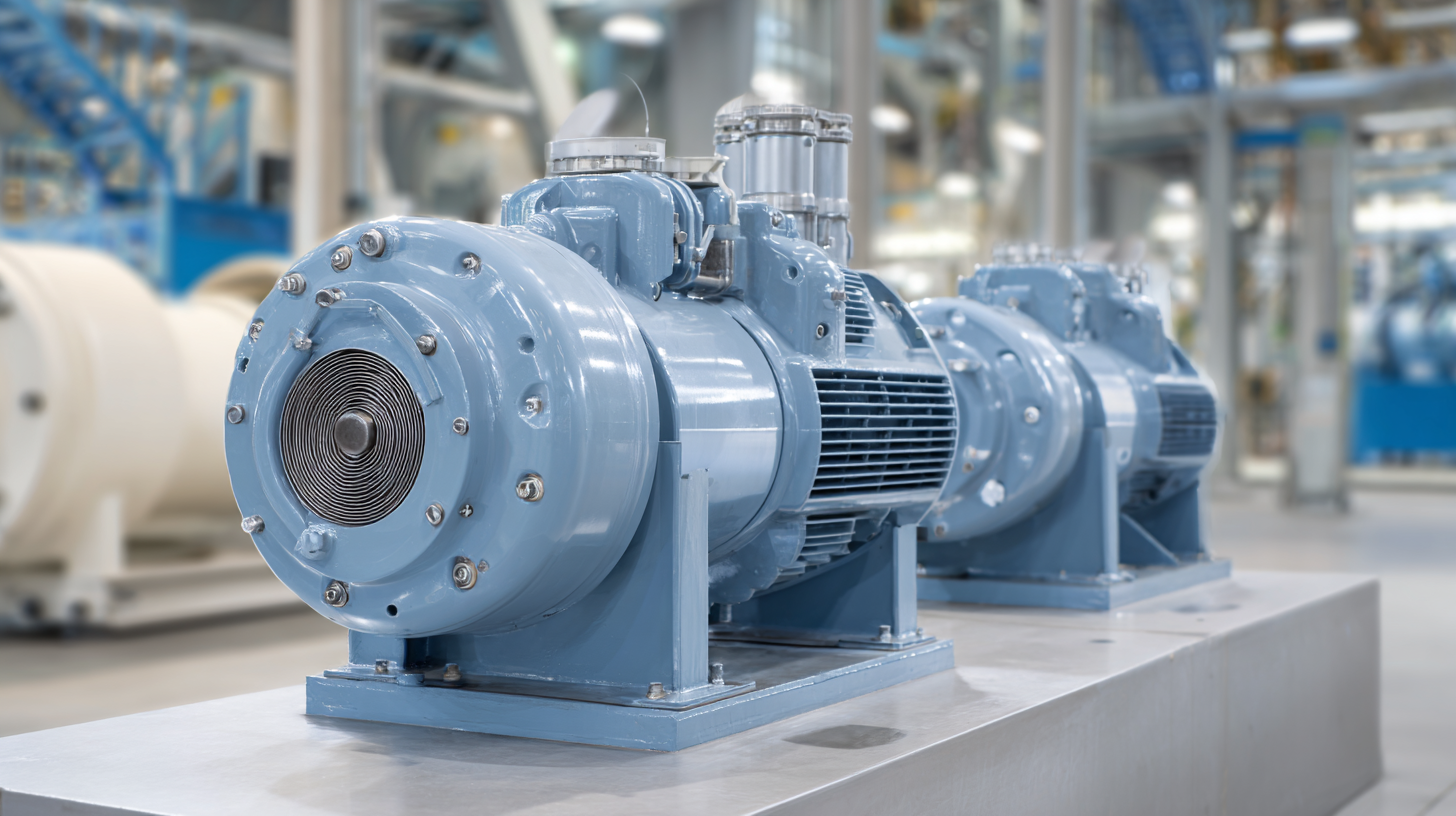

Maximizing Efficiency: The Impact of Industrial Vacuum Blowers on Energy Consumption in Manufacturing

In the ever-evolving landscape of manufacturing, the quest for efficiency and sustainability has never been more critical. One pivotal component in this pursuit is the industrial vacuum blower, a device that significantly influences energy consumption patterns within manufacturing facilities. According to a recent report by the International Energy Agency (IEA), industrial processes account for nearly 30% of global energy demand, highlighting the urgent need for industries to adopt energy-efficient technologies. By optimizing airflow and reducing operating costs, industrial vacuum blowers play an essential role in this transformation.

Renowned industry expert Dr. Emily Carter emphasizes the importance of these systems, stating, "Implementing advanced industrial vacuum blower technology not only reduces energy consumption but also enhances overall operational efficiency." This sentiment is echoed in a study published by the Association of Energy Engineers, which found that facilities utilizing modern industrial vacuum blowers could achieve energy savings of up to 40%. As manufacturers increasingly adopt these innovations, the impact on energy consumption and sustainability practices becomes profoundly evident.

Embracing technological advancements in industrial vacuum blowers is not just a trend; it represents a strategic imperative for forward-thinking organizations aiming to thrive in a competitive marketplace.

Efficiency Advantages of Industrial Vacuum Blowers in Modern Manufacturing Processes

The efficiency advantages of industrial vacuum blowers in modern manufacturing processes are increasingly being recognized as critical for optimizing energy consumption. These blowers not only streamline production workflows but also significantly reduce operational costs. By employing advanced technologies, such as variable speed drives, industrial vacuum blowers can adjust their performance based on real-time demands. This adaptability minimizes energy waste, allowing manufacturers to achieve high levels of vacuum generation without excessive energy expenditure.

Furthermore, industrial vacuum blowers enhance the overall sustainability of manufacturing operations. Unlike traditional systems, which often rely on positive displacement mechanisms, vacuum blowers are designed to efficiently move air and other gases, resulting in lower energy use and fewer greenhouse gas emissions. The shift toward these blowers can lead to substantial energy savings, thereby supporting manufacturers in their efforts to meet environmental regulations and achieve sustainability goals. Ultimately, the strategic implementation of industrial vacuum blowers not only boosts process efficiencies but also fosters a more responsible approach to energy consumption in the manufacturing sector.

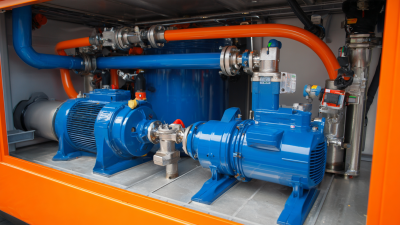

Analyzing Energy Consumption Patterns with Vacuum Blowers vs. Traditional Systems

In the manufacturing sector, energy consumption is a critical factor that directly impacts operational costs and environmental sustainability. When comparing vacuum blowers with traditional systems, the differences in energy efficiency start to emerge. Vacuum blowers, designed for optimal airflow and reduced resistance, often consume significantly less energy than conventional blowers. This efficiency not only results in lower energy bills but also contributes to a smaller carbon footprint for manufacturing operations.

**Tips:** To maximize energy savings, manufacturers should consider the size and capacity of the vacuum blower relative to their specific application. Implementing variable frequency drives (VFDs) can also enhance efficiency by allowing blowers to operate at varying speeds depending on demand, thus avoiding unnecessary energy consumption.

Additionally, regular maintenance of vacuum blower systems is essential for sustained energy performance. Clean filters and well-maintained components ensure that the system operates smoothly, preventing overwork and excess energy use. By adopting these practices, manufacturers can achieve greater efficiency and contribute to a more sustainable production process.

Cost-Benefit Analysis: Long-term Savings with Industrial Vacuum Blowers

Industrial vacuum blowers have emerged as a vital component in modern manufacturing processes, particularly in optimizing energy consumption. By employing advanced technology, these blowers are designed to provide powerful suction while minimizing energy usage. The cost-benefit analysis of integrating industrial vacuum blowers reveals significant long-term savings for manufacturers. Initial investment in these systems is often counterbalanced by lower energy bills, reduced maintenance costs, and enhanced operational efficiency.

Moreover, industrial vacuum blowers contribute to improved workplace safety and product quality, which can further translate to financial benefits. For instance, efficient material handling minimizes waste and ensures consistent production standards, leading to fewer defects. Over time, the cumulative effect of these cost savings can greatly enhance a company's bottom line, making industrial vacuum blowers not only an efficient alternative but also a strategic financial decision. As manufacturers seek to improve their sustainability practices, adopting these innovative systems positions them favorably in a competitive market.

Case Studies: Successful Implementation of Vacuum Blowers in Various Industries

In today's manufacturing landscape, the use of industrial vacuum blowers has emerged as a pivotal solution for enhancing energy efficiency across various sectors. Numerous case studies highlight successful implementations of these systems in diverse industries, demonstrating significant reductions in energy consumption while maintaining optimal operational output. For instance, a food processing facility reported substantial energy savings by integrating vacuum blowers, which streamlined their production processes and minimized waste.

Another compelling example can be found in the automotive industry, where vacuum blowers have been instrumental in improving the efficiency of paint spray booths. By utilizing vacuum technology, manufacturers were able to achieve better paint atomization, leading to smoother finishes and less overspray. This not only reduced material costs but also contributed to a more sustainable production process. As industries continue to prioritize energy efficiency, the role of industrial vacuum blowers will undoubtedly expand, supporting initiatives aimed at reducing overall energy consumption while boosting productivity.

Future Innovations: Enhancing Energy Efficiency in Vacuum Blower Technology

The future of vacuum blower technology holds immense potential for enhancing energy efficiency in manufacturing processes. As industries strive to reduce operational costs and minimize their carbon footprint, innovative advancements in blower design and materials are paving the way for more sustainable solutions. For instance, the integration of smart sensors and IoT connectivity allows for real-time monitoring and adjustments to airflow and pressure, significantly reducing energy wastage. This level of automation not only maximizes performance but also extends the lifespan of equipment, driving down maintenance costs.

Moreover, the focus on advanced motor technologies, such as variable frequency drives (VFDs), is revolutionizing how vacuum blowers operate. These systems allow for dynamic adjustment of motor speed depending on specific application requirements, enhancing efficiency by ensuring that energy consumption aligns closely with demand. By leveraging cutting-edge materials, manufacturers can also create blowers that are lighter, quieter, and more durable, contributing to an overall reduction in energy usage. As these innovations continue to evolve, the manufacturing sector can expect to see substantial improvements in both productivity and sustainability through enhanced vacuum blower technology.

Maximizing Efficiency: The Impact of Industrial Vacuum Blowers on Energy Consumption in Manufacturing - Future Innovations: Enhancing Energy Efficiency in Vacuum Blower Technology

| Energy Source | Power Consumption (kW) | Efficiency (%) | Annual Energy Cost ($) | Potential Savings (%) |

|---|---|---|---|---|

| Electricity | 50 | 85 | 4,500 | 15 |

| Natural Gas | 70 | 90 | 5,200 | 20 |

| Compressed Air | 60 | 80 | 4,800 | 10 |

| Renewable Energy | 40 | 95 | 3,600 | 25 |

Related Posts

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

The Impact of Vacuum Blowers on Reducing Environmental Noise Pollution

-

Exploring the Benefits of Tank Vacuum Systems: A Comprehensive Guide for Homeowners

-

Understanding Waste Pumps How They Work and Their Importance in Modern Waste Management

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems