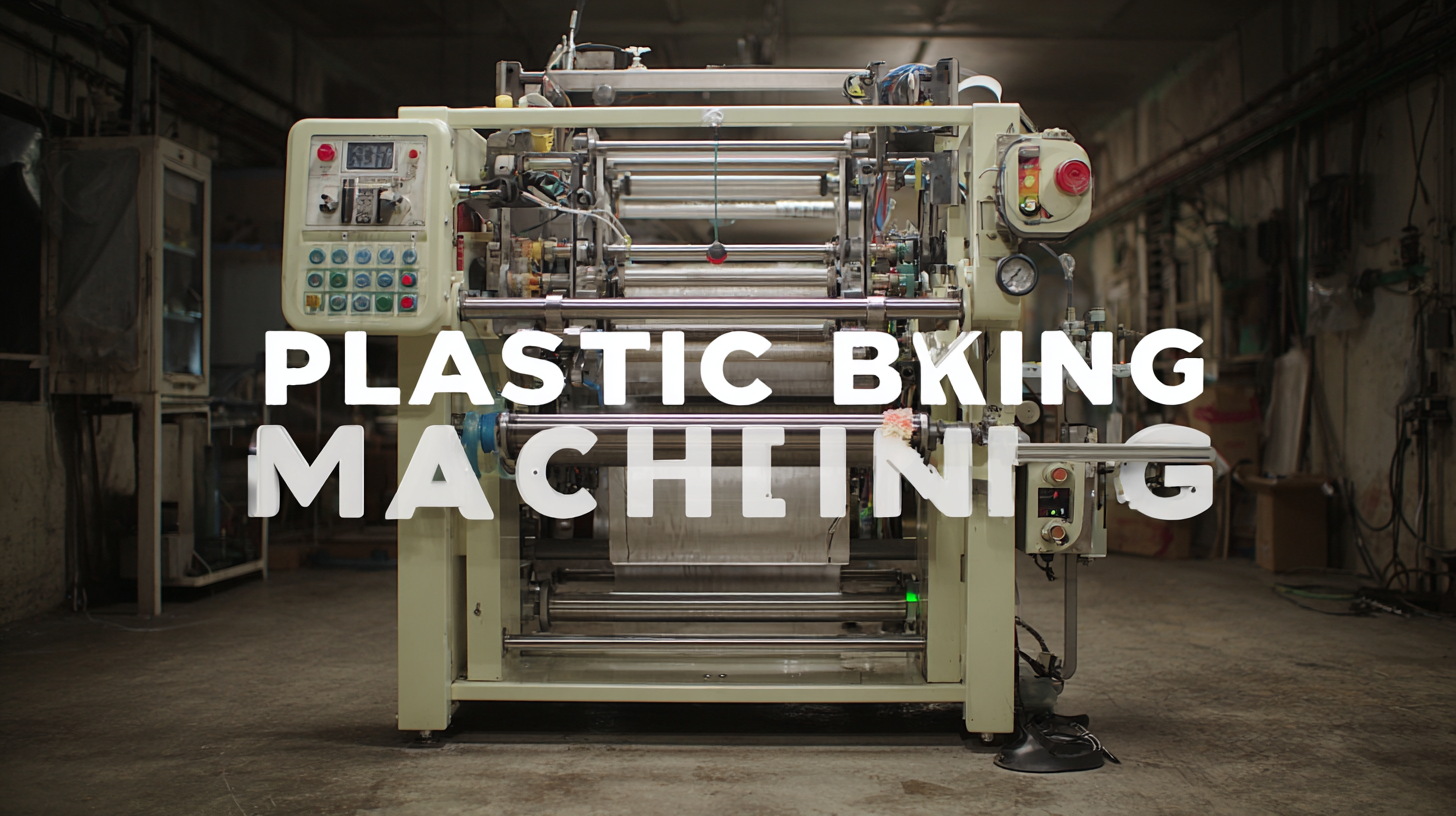

Maximizing Efficiency and Profit: The Benefits of Investing in the Best Plastic Bag Making Machine

In today's fast-paced manufacturing landscape, the need for efficiency and sustainability has never been more crucial, particularly in the packaging industry. Investing in a high-quality Plastic Bag Making Machine can significantly enhance production capabilities and profitability. According to a recent market report by Research and Markets, the global plastic bag manufacturing industry is projected to reach $6.18 billion by 2025, driven by rising consumer demand for convenience and eco-friendly alternatives.

Advanced plastic bag making machines not only streamline production processes but also reduce material waste, aligning with industry standards for sustainability. With the right equipment, companies can produce up to 300 bags per minute, increasing output while maintaining quality. This blog will explore the technical specifications of the top-performing plastic bag making machines and highlight the benefits of investing in this essential technology to maximize efficiency and profit.

Benefits of Investing in High-Quality Plastic Bag Making Machines for Your Business

When it comes to running a successful business, the quality of your equipment can make all the difference. Investing in high-quality plastic bag making machines is a strategic move that can significantly enhance your operations. These state-of-the-art machines are designed to produce bags efficiently, ensuring that production lines remain streamlined and that you can meet customer demand without delays. The speed and precision of these machines reduce waste and downtime, ultimately leading to more efficient processes.

Additionally, high-quality machines offer versatility and durability that can align with various business needs. They can handle different types of materials and sizes of bags, providing the flexibility to adapt to changing market demands. This versatility not only increases your product offerings but also opens up new revenue streams. Moreover, durable machines require less maintenance and have a longer lifespan, allowing for better long-term investment returns. In a competitive market, the benefits of investing in superior plastic bag making technology can drive profitability and elevate your business to new heights.

Maximizing Efficiency and Profit: The Benefits of Investing in the Best Plastic Bag Making Machine

| Feature | Description | Benefit |

|---|---|---|

| High Production Speed | Machines capable of producing up to 200 bags per minute. | Increases output, meeting higher demand. |

| Durable Build Quality | Constructed with high-quality materials to resist wear. | Reduces maintenance costs and downtime. |

| Customizable Options | Allows adjustment for bag sizes and designs. | Enhances product offerings and customer satisfaction. |

| Energy Efficiency | Utilizes technology to minimize energy consumption. | Lowers operational costs, improving profit margins. |

| Advanced Automation | Incorporates automated features for precision and speed. | Improves efficiency and reduces labor costs. |

Understanding After-Sales Service Advantages in Plastic Bag Production Equipment

When investing in a plastic bag making machine, understanding the advantages of after-sales service can significantly impact production efficiency and profitability. According to a report by the Plastics Industry Association, companies that utilize advanced plastic making technology can achieve up to a 20% increase in production output. However, this potential can diminish without reliable after-sales support. Quality service ensures that machines operate at their peak, minimizing downtime caused by unexpected maintenance.

Furthermore, studies show that having robust after-sales service—including timely repairs and access to spare parts—can reduce operational costs by as much as 15%. This is vital in a competitive market, where every minute of idle production translates into lost revenue. Investing in a machine with strong after-sales support not only enhances the immediate manufacturing process but also contributes to long-term sustainability by ensuring that the equipment is consistently optimized for peak performance.

Cost-Effective Maintenance: Reducing Repair Expenses on Plastic Bag Making Machines

Investing in a high-quality plastic bag making machine is a strategic move for businesses looking to maximize efficiency and profit. However, the benefits extend beyond initial purchase considerations. One crucial aspect that often gets overlooked is the cost-effective maintenance of these machines. Regular maintenance not only prolongs the lifespan of the equipment but also significantly reduces repair expenses. By being proactive, companies can avoid costly downtime, ensuring that production runs smoothly without unexpected interruptions.

Implementing a routine maintenance schedule can lead to significant savings in the long run. Simple tasks such as lubrication, calibration, and regular inspections can prevent minor issues from escalating into major repairs. Additionally, investing in training for operators on proper handling and maintenance protocols can minimize wear and tear, thus lowering the likelihood of breakdowns. Companies can also consider utilizing predictive maintenance technologies that leverage data analytics to identify potential issues before they become serious problems, further cutting costs associated with repairs and inefficiencies.

Maximizing Production Efficiency through Upgrades and Technology in Bag Manufacturing

In the competitive landscape of bag manufacturing, maximizing production efficiency through strategic upgrades and advanced technology is crucial. Recent studies indicate that companies that invest in state-of-the-art plastic bag making machines can improve their production rates by up to 30% while simultaneously reducing material waste by around 15%. These upgrades are not just about increasing output; they also enhance the consistency and quality of the bags produced, leading to higher customer satisfaction and lower return rates.

Furthermore, integrating automation and smart technology into the bag manufacturing process allows for real-time monitoring and adjustments, which can further streamline operations. According to a report by Smithers Pira, the market for automated manufacturing technologies in the packaging sector is projected to grow at a CAGR of 7.4% over the next five years. By adopting these innovations, manufacturers can benefit from significant cost savings and operational efficiencies, ultimately driving higher profit margins and ensuring their competitiveness in an ever-evolving market.

Essential Tips for Choosing the Right Plastic Bag Making Machine for Your Operations

When investing in a plastic bag making machine, one of the key considerations is efficiency, which directly impacts your business's productivity and profitability. According to the recent industry report, a high-speed servo wicketer can achieve impressive production rates of over 400 cycles per minute (cpm), delivering high-quality stacks of bags. This capability not only enhances operational efficiency but also minimizes downtime, allowing businesses to meet fluctuating demand with ease.

Selecting the right plastic bag making machine also involves understanding the various features available. For instance, machines equipped with advanced wicket punch capabilities facilitate more efficient handling and packaging. The IMARC Group's report highlights that the investment in modern machinery can significantly reduce setup costs in a garbage bag manufacturing plant. By choosing machines that integrate automation and smart technology, companies can streamline their processes, ultimately leading to increased profit margins and a better return on investment.

Maximizing Efficiency and Profit: Plastic Bag Making Machine Performance

This chart displays the production efficiency of various plastic bag making machines. As seen, Machine D has the highest production rate, emphasizing the importance of investing in the right equipment to maximize operational efficiency and profit margins.