Navigating Import Export Certification for the Best Rewinding Machine a Comprehensive Tutorial

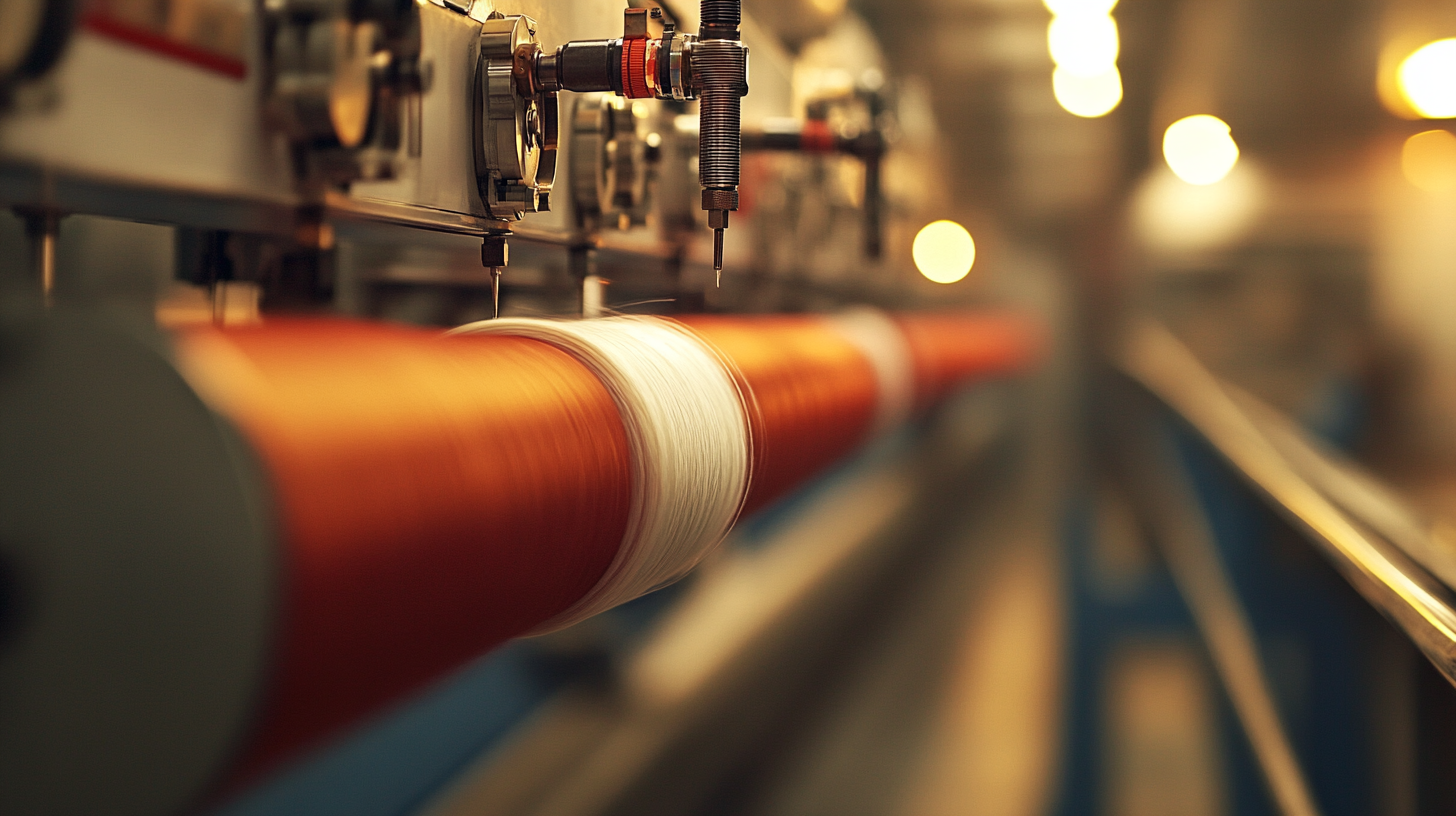

In the ever-evolving landscape of the import-export sector, the demand for efficient and high-quality machinery is paramount, particularly for devices like the Rewinding Machine. According to a recent report by MarketsandMarkets, the global rewinding machine market is anticipated to grow at a CAGR of 4.8% from 2021 to 2026, driven by advancements in packaging technologies and increasing consumer goods production. This growth underscores the essential nature of understanding the regulatory landscape surrounding import-export certification for such equipment. Compliance with international standards not only ensures product reliability but also facilitates smoother transactions across borders.

This tutorial aims to provide a comprehensive guide on navigating the complexities of certification for the best Rewinding Machine, helping businesses optimize their operations while meeting all necessary legal requirements.

Understanding the Importance of Import Export Certification for Rewinding Machines

Import export certification plays a crucial role in the global trade of rewinding machines, a critical component in various manufacturing sectors.

According to a recent report by MarketsandMarkets, the rewinding machine market is projected to reach $2.5 billion by 2026, driven by increasing demand in industries such as packaging, textiles, and printing.

However, manufacturers and exporters must navigate the complexities of import export certification to ensure compliance with international standards, which can significantly affect market access and competitiveness.

Understanding the importance of these certifications is essential for businesses involved in the trade of rewinding machines.

Specific certifications, such as ISO 9001 and CE marking, not only enhance product credibility but also facilitate smoother entry into foreign markets.

According to a study by the World Bank, compliant products have a 30% higher chance of passing customs inspections, thereby reducing delays and associated costs.

By securing the necessary certifications, manufacturers can demonstrate their commitment to quality and safety, ensuring that their rewinding machines meet the diverse regulations of global markets.

Key Certification Requirements for Rewinding Machine Imports and Exports

When considering the intricacies of importing and exporting rewinding machines, understanding the key certification requirements is crucial for ensuring compliance and a smooth transaction. Different countries have specific regulations that govern the import and export of industrial machinery, including rewinding machines. Typically, these requirements encompass safety certifications, environmental compliance, and quality standards. For example, certifications like CE marking in Europe or UL certification in the United States signify that the machinery meets essential safety and performance criteria.

Additionally, it is vital for businesses to recognize the importance of documentation, which may include import/export licenses, customs declarations, and operational manuals in the desired language. These documents not only facilitate a transparent transaction but also safeguard against potential legal challenges. Understanding the nuances of these certification requirements can help businesses avoid costly delays and ensure that their rewinding machines meet the necessary standards, ultimately leading to successful international trade. Keeping abreast of changes in regulatory landscapes is equally important, as this will help manufacturers and importers maintain compliance and stay competitive in the global market.

Navigating Import Export Certification for the Best Rewinding Machine

| Certification Requirement | Description | Region | Authority |

|---|---|---|---|

| CE Marking | Indicates conformity with health, safety, and environmental protection standards. | European Union | European Commission |

| UL Certification | Ensures that products meet safety standards in the United States. | United States | Underwriters Laboratories |

| ISO 9001 | Specifies requirements for a quality management system. | Global | International Organization for Standardization |

| RoHS Compliance | Restricts the use of specific hazardous materials in electrical and electronic equipment. | European Union | European Parliament |

| FCC Compliance | Ensures that electronic devices do not cause harmful interference. | United States | Federal Communications Commission |

Step-by-Step Process for Obtaining Rewinding Machine Certification

Navigating the complexities of obtaining certification for rewinding machines can seem daunting, but breaking it down into a step-by-step process can simplify the journey. The first step involves understanding the specific certification requirements, which can vary by country or region. Contacting the relevant regulatory bodies will provide clarity on the standards your rewinding machine must meet. Ensure that you gather all necessary documentation, including technical specifications, design details, and safety compliance records.

Once you have an understanding of the requirements, the next phase is preparation. This includes performing thorough tests on the rewinding machine to verify its efficiency and safety measures. It’s vital to compile all test results and maintain detailed records, as these will be required during the certification audit. Engaging with a local certification consultant can also be beneficial, as they can guide you through the nuances of the certification process and help you address any potential issues before the official review.

Finally, submit your application along with all supporting documentation. After submission, an inspection will be scheduled, where officials will assess your rewinding machine against the required standards. Being well-prepared for this inspection by ensuring your machine is compliant can significantly enhance your chances of obtaining certification without delays. By following these steps, you can effectively navigate the certification process and get your rewinding machine ready for the market.

Common Challenges in Import Export Certification and How to Overcome Them

Navigating the complexities of import-export certification can be daunting, especially when sourcing machinery like the best rewinding machine. Many businesses face common challenges, such as understanding the certification requirements of various countries and the intricacies of customs regulations. These hurdles can lead to delays, increased costs, and even legal issues if not managed effectively.

Tip: To streamline the certification process, make sure to gather all necessary documentation early. This includes invoices, shipping documents, and proof of compliance with international standards. Keeping organized records will not only expedite approvals but also minimize the risk of oversights that could halt your project.

Another common challenge is adapting to different regulations and standards. These can vary greatly from one region to another, making it crucial for importers and exporters to stay informed about the latest requirements. Regularly consulting with trade experts or legal advisors can provide valuable insights and prevent potential pitfalls in your operations.

Tip: Establish a timeline that outlines all certification stages. This proactive approach allows you to anticipate deadlines, ensuring you allocate sufficient time for each step. Regularly review and adjust your timeline as needed, keeping in mind that unexpected challenges may arise during the process.

Navigating Import Export Certification Challenges

Best Practices for Ensuring Compliance with Certification Standards in Rewinding Machines

When it comes to navigating import and export certification for rewinding machines, compliance with certification standards is paramount. According to a report by MarketsandMarkets, the global rewinding machine market is expected to reach $3.2 billion by 2025, highlighting the increasing demand for high-quality, compliant machines. To ensure that your rewinding machine meets industry standards, it is essential to stay informed about local and international regulations that affect certification processes. These regulations often encompass safety, performance, and environmental impact criteria, which can vary significantly from one region to another.

When it comes to navigating import and export certification for rewinding machines, compliance with certification standards is paramount. According to a report by MarketsandMarkets, the global rewinding machine market is expected to reach $3.2 billion by 2025, highlighting the increasing demand for high-quality, compliant machines. To ensure that your rewinding machine meets industry standards, it is essential to stay informed about local and international regulations that affect certification processes. These regulations often encompass safety, performance, and environmental impact criteria, which can vary significantly from one region to another.

Best practices for ensuring compliance include adopting a rigorous quality management system (QMS) that aligns with ISO 9001 standards. This approach not only reinforces operational efficiency but also builds customer trust. Furthermore, collaborating with certified third-party testing organizations can provide valuable insights and help verify compliance before entering the market. The International Electrotechnical Commission (IEC) has also emphasized the importance of adhering to their standards, which can reduce the risk of product recalls and enhance the overall reputation of your machinery. In an era where regulatory requirements are continuously evolving, maintaining a proactive stance towards certification can set companies apart in the competitive landscape of rewinding machine production.