Future Innovations in Bag Forming Machines and Key Approaches to Industry Growth

In the ever-evolving landscape of the packaging industry, the demand for advanced Bag Forming Machines is surging, as companies strive to enhance efficiency and sustainability. According to a recent report by MarketsandMarkets, the packaging machinery market is projected to reach USD 50.8 billion by 2025, growing at a CAGR of 4.5% from 2020. This growth underscores the pivotal role that innovative bag forming technology plays in meeting consumer needs and regulatory demands for eco-friendly packaging solutions.

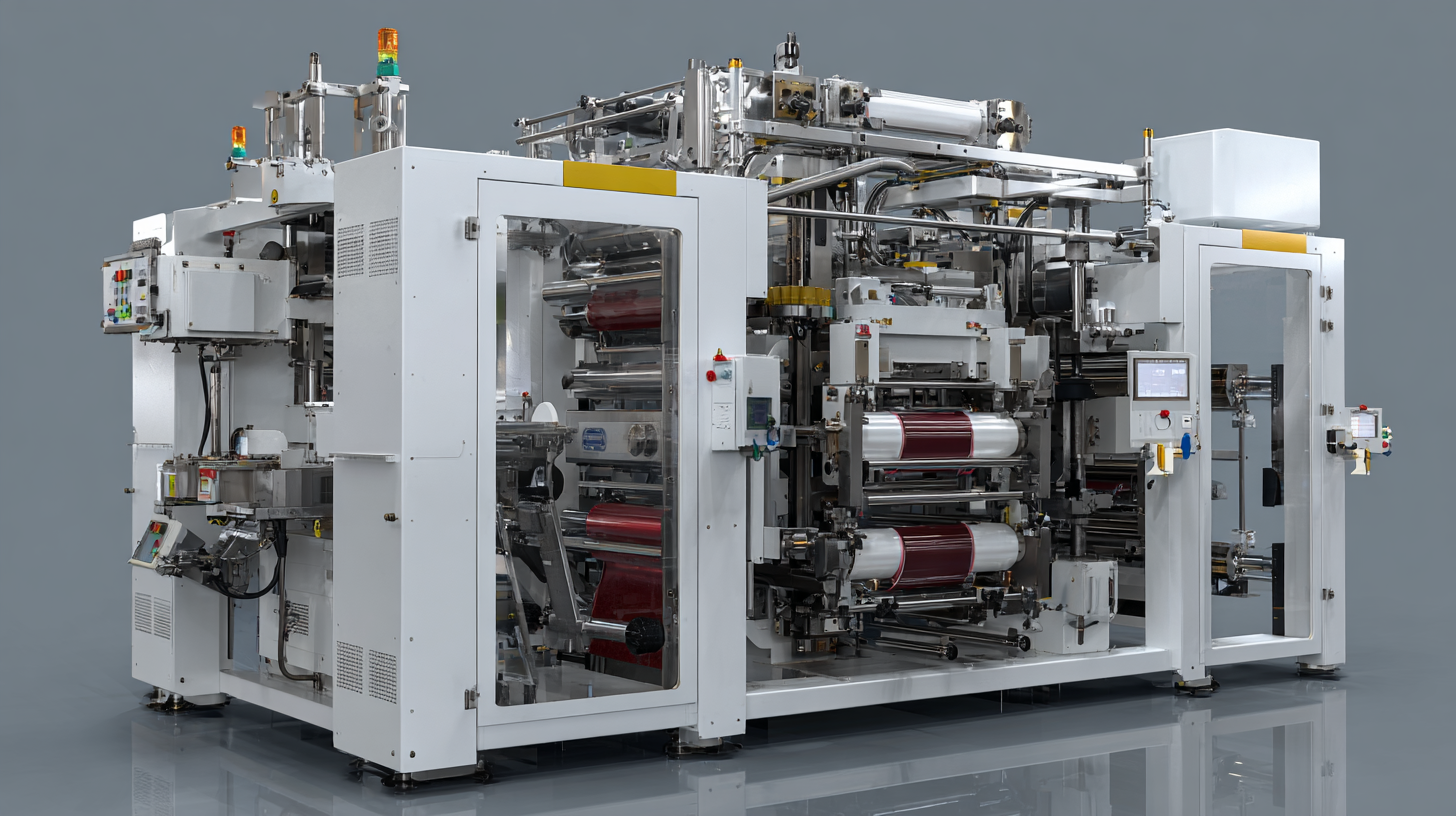

With the rise of automation and smart manufacturing, businesses are increasingly investing in Bag Forming Machines equipped with cutting-edge features that improve speed, precision, and material usage. As we explore future innovations in this field, it is crucial to delve into the key approaches that will drive industry growth and sustainability, ultimately shaping the future of packaging.

With the rise of automation and smart manufacturing, businesses are increasingly investing in Bag Forming Machines equipped with cutting-edge features that improve speed, precision, and material usage. As we explore future innovations in this field, it is crucial to delve into the key approaches that will drive industry growth and sustainability, ultimately shaping the future of packaging.

Innovative Technologies Reshaping Bag Forming Machines in 2023

The bag forming machine industry is experiencing a significant transformation in 2023, driven by innovative technologies that enhance efficiency and sustainability. Recent advancements have introduced automation and smart technology, allowing for rapid customization and production of bags to meet diverse market demands. According to industry reports, the global market for bag forming machines is expected to grow at a compound annual growth rate (CAGR) of over 5% from 2023 to 2030, reflecting the increasing demand for eco-friendly packaging solutions.

Sustainability remains a core focus as manufacturers are integrating advanced materials that reduce environmental impact. Innovations such as biodegradable films and reusable packaging options are gaining traction, reshaping how products are packaged and shipped. These developments align with broader trends in the manufacturing sector, where sustainability is becoming a deal-breaker for consumers and businesses alike. Moreover, the shift from "Made in China" to "Innovated in China"—as highlighted by recent exhibitions—illustrates a regional commitment to leading the market through technology rather than mere production costs. Thus, as new technologies are woven into the fabric of bag forming machines, the potential for industry growth continues to expand, promising a future rich in innovation and responsibility.

Sustainability Trends Driving Growth in the Bag Manufacturing Industry

As the bag manufacturing industry continues to evolve, sustainability emerges as a crucial trend driving innovation and growth. Manufacturers are increasingly prioritizing eco-friendly materials and practices, leading to the development of new bag forming technologies that minimize environmental impact. For instance, biodegradable and recyclable materials are becoming standard, prompting a shift in consumer preferences towards sustainable packaging solutions. The integration of these materials not only caters to environmental consciousness but also opens avenues for brands to differentiate themselves in a competitive market.

Moreover, the expansion of the hand sanitizer market highlights a significant change in consumer behavior, as hygiene products are now often sold in various packaging forms such as bottles, pouches, and wipes. This trend reflects a broader demand for convenience and practicality in packaging.

As brands adapt to these changing preferences, the bag forming machines are not only required to innovate in terms of materials but also in terms of design and functionality. This adaptability is essential for capturing market share as the global market continues to grow, with the overall retail sales for bags surpassing significant milestones year over year.

Automation: Enhancing Efficiency in Bag Forming Processes

The evolution of bag forming machines is increasingly centered around automation, a key driver for enhancing efficiency in bag forming processes. According to a recent report by the International Society of Automation, companies that implement automated systems in their production lines have noted a 30% increase in operational efficiency. This leap in productivity is largely attributed to decreased cycle times and minimized human error, allowing businesses to meet rising consumer demands without compromising quality.

Furthermore, advancements in technology, such as the integration of Industry 4.0 concepts, are revolutionizing the bag manufacturing landscape. The market for automated bag forming machines is predicted to grow at a CAGR of 5.1% from 2023 to 2028, as stated in a survey by Grand View Research. This growth is indicative of the industry's shift towards smart manufacturing solutions, where data-driven decisions enhance process optimization. By adopting automation, manufacturers not only streamline their operations but also position themselves favorably in an increasingly competitive market, capable of responding swiftly to changes in consumer preferences and economic landscapes.

Key Market Drivers: Demand for Customization and Flexibility in Packaging

The packaging industry is undergoing a significant transformation driven by the demand for customization and flexibility. With the global pharmaceutical contract packaging market projected to reach USD 34.80 billion by 2034, a notable CAGR of 7.34% highlights the increasing urge for tailored packaging solutions. This shift is largely influenced by end-users seeking specialized containers that meet varying regulatory requirements and consumer preferences. The ability to deliver customized packaging not only enhances product appeal but also plays a crucial role in maintaining product integrity, particularly in the pharmaceutical sector.

Moreover, the flexible packaging market is anticipated to soar to USD 301 billion by 2031, indicating a robust trend towards adaptable packaging solutions across multiple industries. Factors driving this growth include the rising demand for convenience, sustainability, and cost-effectiveness in product packaging. As e-commerce continues to expand, the need for packaging that can accommodate diverse sizes and shapes while still being eco-friendly has never been more critical. Consequently, companies that innovate in bag forming technology are likely to lead the way in meeting these evolving market demands, paving the path for sustainable growth in the industry.

Future Prospects: Market Forecast and Investment Opportunities in Bag Forming Machines

The bag forming machines market is poised for substantial growth, with experts forecasting a market size of approximately $2.1928 billion by 2025. This expansion reflects a compounded annual growth rate (CAGR) of 2.45%, indicating a steady demand for innovative solutions in the packaging sector. As consumer preferences evolve, companies are increasingly seeking advanced production technologies that enhance efficiency and sustainability.

Investment opportunities abound as the industry adapts to emerging trends. Bag forming machines are crucial for producing various packaging solutions, from biodegradable materials to multi-layered films that improve shelf life. By 2033, the market is projected to reach $2.6613 billion, highlighting the need for manufacturers to focus on integrating automation and smart technologies into their systems. Such advancements not only improve production speed but also offer a significant reduction in waste, aligning with global sustainability goals.