- Eng

- Deu

- Fra

10 Essential Tips for Choosing the Right Vacuum Oil for Your Equipment

Choosing the right vacuum oil is crucial for maintaining the efficiency of your equipment. According to a report by Industry Research Group, improper oil selection can lead to a 25% decrease in performance. The right vacuum oil ensures optimal sealing and cooling, which are vital for operation.

Expert John Miller, a renowned specialist in lubricant technologies, emphasizes, "A well-chosen vacuum oil can extend equipment life significantly." Many industries underestimate the impact of vacuum oil quality. A mismatch can result in increased costs and downtime, potentially costing companies thousands.

Assessing vacuum oil involves more than just compatibility. Consider factors like viscosity, thermal stability, and chemical reactivity. Pay attention to the specific needs of your equipment. Many businesses overlook minor details, assuming all oils perform similarly. Reflecting on these choices can yield better outcomes and more reliable operation.

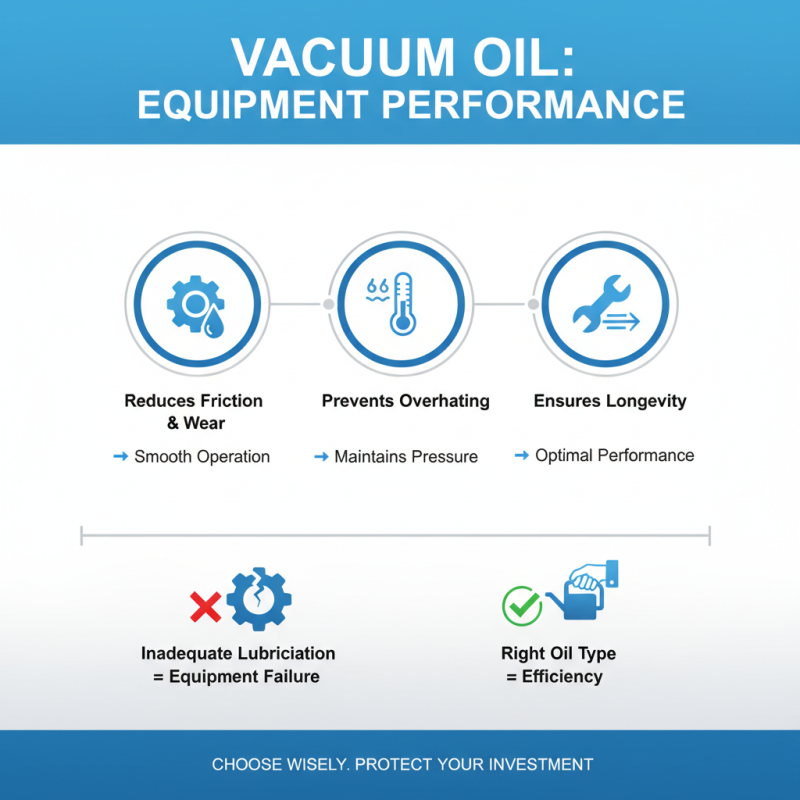

Understanding the Importance of Vacuum Oil in Equipment Performance

Vacuum oil plays a crucial role in the performance of various equipment. It reduces friction and wear, ensuring smooth operation. The right oil can prevent overheating and maintain optimal pressure levels. Inadequate lubrication can lead to equipment failure or decreased efficiency. Choosing the appropriate vacuum oil is essential for longevity.

When selecting vacuum oil, consider its viscosity and temperature range. Oils that are too thick can hinder performance. Conversely, oils that are too thin may not provide sufficient protection. Look for oils that match your equipment's specifications. Additionally, different applications might require specific formulations.

It’s important to stay vigilant about oil quality. Contaminated oil can cause serious problems. Regularly check for signs of degradation or contamination. In some cases, it may be tempting to use leftover oil from previous jobs. This decision could lead to more significant issues down the line. Always prioritize your equipment's needs over convenience.

Key Properties to Look for in Quality Vacuum Oil

Choosing the right vacuum oil is crucial for equipment efficiency. Key properties to consider include viscosity, thermal stability, and purity. Viscosity influences the oil’s ability to lubricate and maintain optimal performance. An ideal viscosity range should match your equipment’s specifications. Data from industry reports show that a 15 cSt oil can reduce friction by up to 25% in some vacuum systems, enhancing overall productivity.

Thermal stability is another essential factor. High-quality vacuum oils resist thermal degradation at elevated temperatures. According to research, oils with high thermal stability can maintain their viscosity for longer. This prolongs the life of your equipment and reduces maintenance costs. Additionally, the oil's purity affects its performance. Contaminated oils can lead to failure. Studies indicate that even a small percentage of impurities can negatively impact a system’s efficiency and lifespan.

Consider the operating environment when selecting oil. Certain conditions may require specialized formulations. For instance, in cleanroom environments, low outgassing properties are essential. It's vital to review data sheets carefully. Look for lab reports that specify performance under varied conditions. Not all oils perform the same in extreme environments. Selection based on wrong assumptions can lead to costly downtimes and repairs. Sometimes, what appears to be a suitable option might not be effective in practice.

Comparing Mineral vs. Synthetic Vacuum Oils: Pros and Cons

When it comes to vacuum oils, the choice between mineral and synthetic can be daunting. Mineral oils are derived from natural sources. They tend to be less expensive. However, they may have lower thermal stability. This can lead to quicker degradation under high temperatures. Synthetic oils, on the other hand, are engineered for specific properties. They often resist oxidation and have a longer lifespan. This can enhance the performance of your equipment significantly.

Tips for choosing vacuum oil include evaluating temperature ranges. The oil must be able to withstand the conditions in your operation. Consider factors like viscosity as well. Thicker oils can provide a better seal, but may not always be the best choice. Always look for compatibility with your equipment materials. It's crucial to avoid cross-contamination with incompatible fluids.

Reflect on your maintenance routine as well. Regularly changing vacuum oil can prevent build-up and ensure efficiency. Some users overlook this step, leading to equipment failure. Keep in mind that choosing the right oil is an investment. The right decision can save you from costly repairs and downtime.

Comparison of Mineral vs. Synthetic Vacuum Oils

This chart compares the essential qualities of mineral and synthetic vacuum oils across various criteria that are critical for equipment performance. Each criterion is rated on a scale of 1 to 10, where 10 represents superior performance.

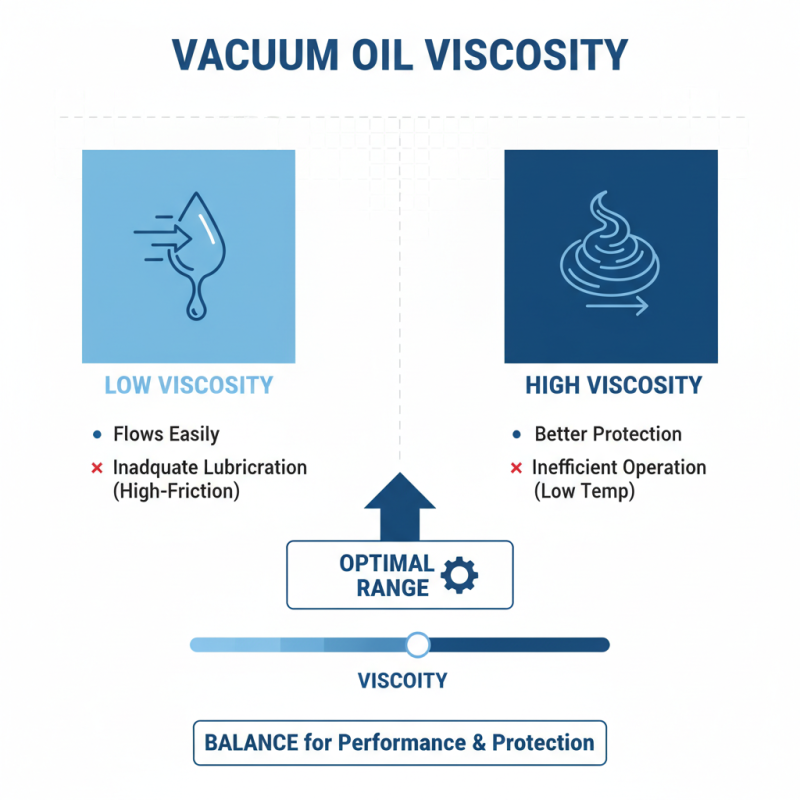

Recognizing the Impact of Viscosity on Vacuum Oil Selection

When selecting vacuum oil, viscosity plays a crucial role. Viscosity determines how easily the oil flows under pressure. A lower viscosity may seem appealing at first. Yet, it can lead to inadequate lubrication in high-friction environments. Conversely, high-viscosity oils may offer better protection but can lead to inefficient operation at low temperatures.

Understanding your equipment's operating conditions is vital. Is the machinery often exposed to extreme heat? Choose a oil with a higher viscosity rating to ensure proper functioning. Conversely, if your equipment runs cooler, a lower viscosity oil may suffice. However, it’s essential to note that what works in one scenario may not apply universally. Testing different viscosities can yield unexpected insights.

Emphasize the importance of viscosity in achieving optimal performance. Many users overlook this factor. They may choose oil based on price or availability instead. This can lead to operational inefficiencies or damaging equipment. Always consider viscosity as a key parameter in your selection process. The right choice can improve performance and extend equipment life.

Evaluating Manufacturer Specifications and Industry Standards for Vacuum Oils

When selecting vacuum oil, evaluating manufacturer specifications and industry standards is crucial. Always check the oil's viscosity rating. It affects the oil's performance in your equipment. Different machines have varying requirements. Some may not work well with oils that exceed specific viscosity levels.

A key consideration is the oil's thermal stability. An oil that can withstand high temperatures often prolongs equipment life. Research the oil's flash point and pour point. These factors can determine how well the oil performs under pressure. Ignoring them could lead to insufficient lubrication and mechanical failure.

Tip: Often, the cheapest option isn't the best. Quality matters more than cost. Look for oils that meet or exceed industry certifications. This ensures they have passed rigorous testing and meet specific performance criteria. Don't rush this decision; it's essential for your equipment's longevity.

Related Posts

-

How to Choose the Right Vacuum Oil for Your Equipment?

-

Unlocking the Secrets: How Vacuum Oil Enhances Industrial Efficiency and Equipment Longevity

-

Exploring Vacuum Oil: Key Benefits and Industry Trends Influencing Machinery Performance

-

What is Vacuum Oil and How it Benefits Industrial Applications

-

2025 Top Vacuum Oil Types: Key Benefits and Uses You Should Know

-

Why Are Septic Pumps Essential for Your Home System?