- Eng

- Deu

- Fra

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

In the realm of industrial applications, the efficiency and reliability of equipment play a crucial role in operational success. Among such equipment, the rotary vane vacuum pump stands out for its versatility and performance.

According to a report by Markets and Markets, the global vacuum pumps market is projected to reach USD 3.7 billion by 2025, driven by advancements in vacuum technology and increasing demand across various sectors, including food processing, pharmaceuticals, and semiconductor manufacturing.

Understanding the essential performance metrics of rotary vane vacuum pumps, such as pumping speed, ultimate vacuum, and energy consumption, is vital for optimizing their use in demanding industrial environments. This guide aims to explore these key performance indicators to help businesses make informed decisions regarding the selection and maintenance of rotary vane vacuum pumps, ultimately enhancing their operational efficiency and product quality.

According to a report by Markets and Markets, the global vacuum pumps market is projected to reach USD 3.7 billion by 2025, driven by advancements in vacuum technology and increasing demand across various sectors, including food processing, pharmaceuticals, and semiconductor manufacturing.

Understanding the essential performance metrics of rotary vane vacuum pumps, such as pumping speed, ultimate vacuum, and energy consumption, is vital for optimizing their use in demanding industrial environments. This guide aims to explore these key performance indicators to help businesses make informed decisions regarding the selection and maintenance of rotary vane vacuum pumps, ultimately enhancing their operational efficiency and product quality.

How Do Rotary Vane Vacuum Pumps Operate in Industrial Settings?

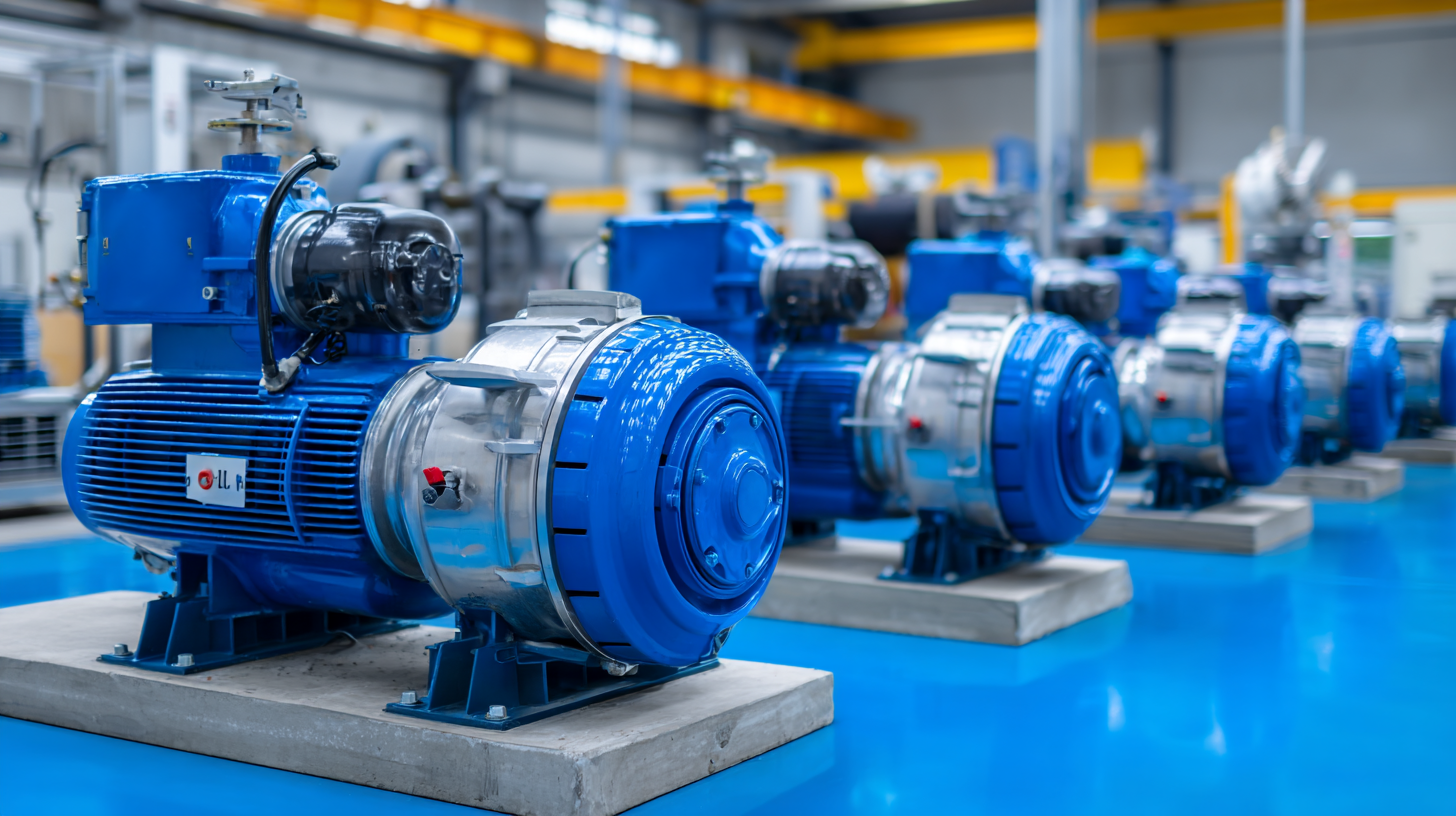

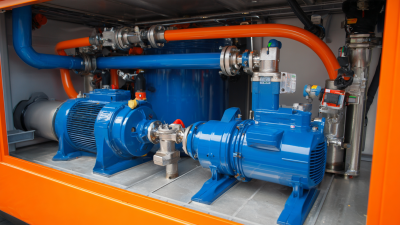

Rotary vane vacuum pumps operate through a simple yet effective mechanism that relies on the rotation of vanes within a cylindrical casing. As the rotor turns, centrifugal force pushes the vanes outward against the wall of the casing, creating separate chambers. These chambers expand and compress, allowing air to be drawn in and expelled, thus generating a vacuum. The design allows for smooth operation and continual performance, making them ideal for various industrial applications such as packaging, food processing, and pharmaceuticals where reliable suction is crucial.

In industrial settings, rotary vane vacuum pumps are favored for their efficiency and robust design under varying workload conditions. Their ability to maintain a consistent vacuum level is essential for processes that require precision, such as vacuum forming and degassing. Additionally, their relatively low maintenance needs and durability make them suitable for long-term use. Industries benefit from the flexibility of these pumps to handle different tasks, whether it’s in a clean room environment or a more rugged industrial area, ensuring they meet the diverse demands of modern manufacturing.

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps

What Are the Key Performance Metrics to Measure for Rotary Vane Vacuum Pumps?

When evaluating rotary vane vacuum pumps for industrial applications, several key performance metrics must be considered to ensure optimal efficiency and longevity. One of the primary metrics is the ultimate vacuum level, which indicates the lowest pressure that the pump can achieve. According to a report by the Vacuum Technology Association, industrial rotary vane pumps typically reach an ultimate vacuum of 0.1 mbar to 1 mbar, making them suitable for applications requiring high levels of evacuation.

Another critical metric is the pumping speed, which measures the volume of gas that can be removed by the pump over a given time, usually expressed in liters per second (L/s). Research published in the Journal of Industrial Vacuum Technology shows that rotary vane pumps can have pumping speeds ranging from 10 L/s to over 200 L/s, depending on the model and application. Additionally, the durability and service life of the pump, often indicated by the maintenance intervals and hours of operation before a major overhaul is required, play a significant role in the operational cost-effectiveness of these pumps in industrial settings. Regular analysis of these metrics ensures that industries make data-driven decisions that enhance productivity and reduce downtime.

Why Efficiency Ratings Matter for Rotary Vane Vacuum Pump Selection?

When selecting rotary vane vacuum pumps for industrial applications, understanding efficiency ratings is crucial for optimal performance. Efficiency ratings directly impact

energy consumption, operational costs, and the overall sustainability of industrial processes.

High-efficiency pumps not only reduce electricity bills but also contribute to lower carbon footprints, aligning with modern environmental standards.

Moreover, efficiency ratings provide insights into how well a pump can maintain its vacuum levels under varying operational conditions. A pump with a high efficiency rating typically demonstrates stable performance and reliability, which are essential in industries where consistent vacuum pressure is critical.

Industrial operators should prioritize these metrics to ensure that they invest in equipment that will meet their specific needs while minimizing operational downtime and maintenance costs.

Choosing the right rotary vane vacuum pump based on its efficiency rating ultimately enhances productivity and effectiveness in industrial applications.

How to Assess Maintenance Needs Based on Performance Metrics?

Assessing the maintenance needs of rotary vane vacuum pumps is crucial for ensuring optimal performance in industrial applications. Performance metrics such as pumping speed, ultimate vacuum level, and power consumption provide significant insights into the operational efficiency of these pumps. According to the "Pump Performance Oversight Report 2022," neglecting to monitor these metrics can lead to a 30% decline in efficiency and an increase in operational costs. Regular assessments not only help identify wear and tear but also uncover potential issues before they lead to costly downtime.

**Tip:** Utilize advanced monitoring systems that include real-time data collection and alert features for key performance metrics. This proactive approach allows for timely maintenance decisions that can extend pump lifespan and reduce repair costs.

When evaluating maintenance needs, it's essential to analyze how often the pump is subjected to peak operating conditions. A report from the "Vacuum Technology Standards Committee" indicates that pumps operating in high-stress environments require maintenance checks every 6 months, as opposed to the typical annual schedule for standard operations. By aligning maintenance with performance data, organizations can optimize their pump utilization and overall productivity.

**Tip:** Keep a detailed log of performance metrics and maintenance activities. This record provides a clear picture of the pump’s operational history, making it easier to predict potential failures and plan necessary interventions.

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

| Metric | Description | Ideal Range | Current Performance | Maintenance Recommendation |

|---|---|---|---|---|

| Vacuum Level (mbar) | The pressure level achieved by the pump. | < 5 mbar | 6 mbar | Consider replacing seals |

| Flow Rate (m³/h) | The volume of air the pump can move in an hour. | >= 30 m³/h | 25 m³/h | Needs inspection for blockages |

| Power Consumption (kW) | The electrical power the pump consumes during operation. | < 4 kW | 5 kW | Check motor efficiency |

| Operating Temperature (°C) | Temperature during pump operation. | < 75 °C | 80 °C | Consider cooling system evaluation |

| Noise Level (dB) | The noise produced during pump operation. | < 70 dB | 75 dB | Inspect for wear and vibration |

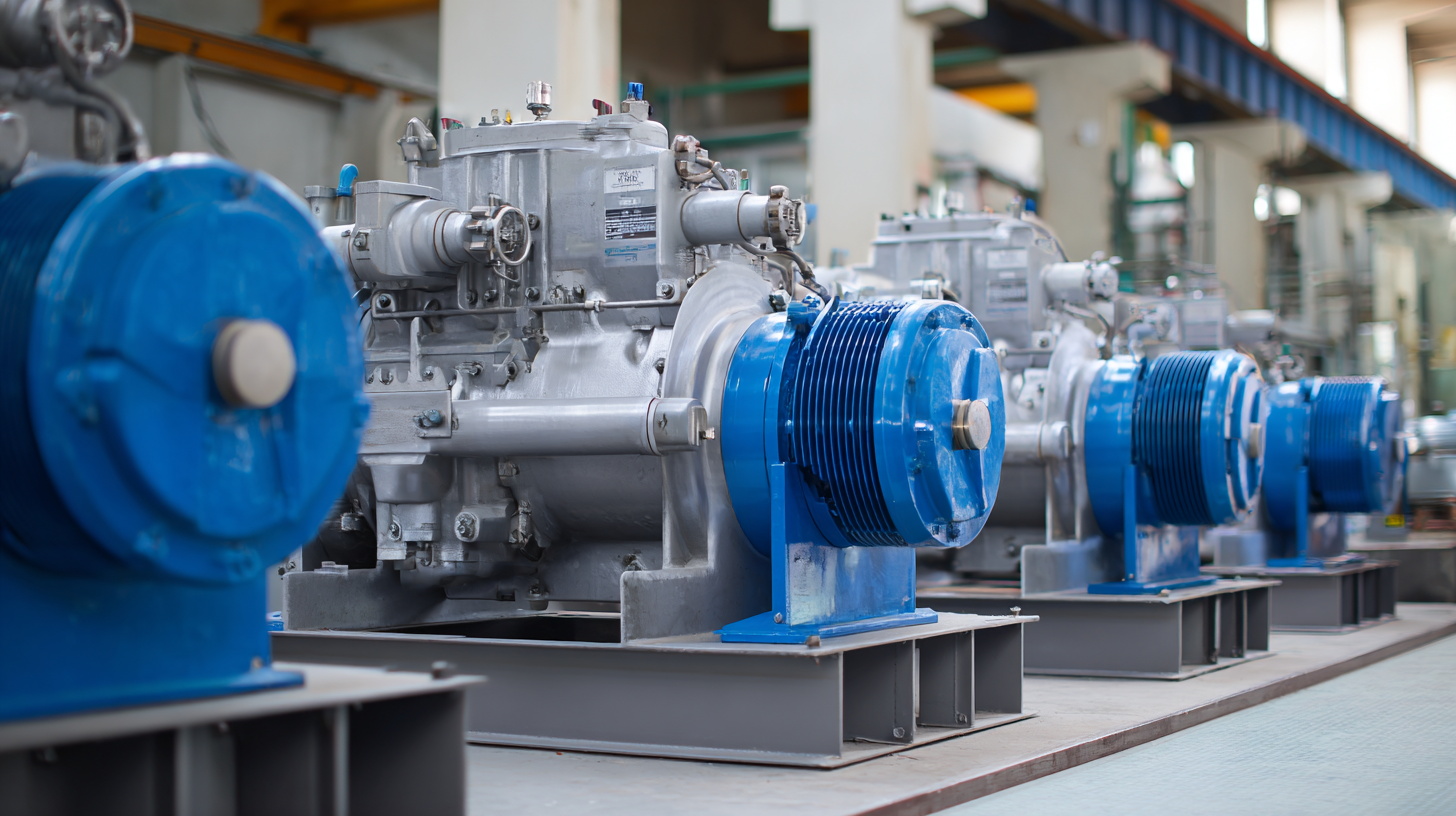

What Role Does Pump Size Play in Optimal Industrial Applications?

When it comes to selecting

rotary vane vacuum pumps for industrial applications, pump size plays a critical role in determining efficiency and effectiveness. A well-sized vacuum pump can significantly influence the operational performance of the system it serves. According to a report by the American Vacuum Society, properly sized pumps can reduce energy consumption by up to 30%. This is particularly important in industries such as pharmaceuticals and food processing, where vacuum levels must be maintained consistently for optimal production quality.

Moreover, the pump's size impacts the speed of evacuation and the overall system throughput. Larger pumps can handle greater airflow rates and are better suited for high-demand applications. However, oversized pumps can lead to inefficiencies, including increased wear and tear, and energy costs. The

Vacuum Technology Association notes that selecting a pump with a capacity that matches the specific needs—based on factors like chamber size and process requirements—can enhance system reliability and extend equipment life. Thus, understanding the nuanced relationship between pump size and application requirements is essential for any industrial setup aiming for peak performance.