- Eng

- Deu

- Fra

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

In today's fast-paced industrial and domestic environments, the importance of vacuum pumps cannot be overstated. According to a report by ResearchAndMarkets, the global vacuum pump market is projected to reach USD 5.9 billion by 2026, growing at a CAGR of 5.2% from 2021. This growth underscores the increasing reliance on vacuum pumps in various applications, from food packaging to medical devices. Understanding the fundamentals of vacuum pumps is essential for anyone looking to optimize their efficiency and effectiveness in everyday tasks. Whether you are a professional seeking to minimize costs in your operations or a DIY enthusiast aiming to enhance your projects, this guide will equip you with essential tips and insights into the various types of vacuum pumps and their applications. Embracing this knowledge will not only empower you to make informed decisions but will also elevate your understanding of how vacuum technology can play a crucial role in improving performance and productivity in multiple settings.

The Importance of Vacuum Pumps in Everyday Applications

Vacuum pumps play a crucial role in numerous everyday applications, making them an indispensable tool across various industries. According to a report by MarketsandMarkets, the global vacuum pump market is expected to reach $5.15 billion by 2025, driven by increasing demand in sectors such as pharmaceuticals, food packaging, and electronics. These devices create a low-pressure environment that enables tasks like preserving food, assisting in medical treatments, and improving manufacturing processes.

In the food industry, for example, vacuum packaging extends the shelf life of products by removing air that promotes oxidation and spoilage. A study by the Food Science Journal highlighted that vacuum-sealed foods show a 30-40% increase in shelf life compared to their conventional packaging counterparts. Furthermore, in the medical field, vacuum pumps are essential for surgical suction systems, which help maintain a clear field by removing blood and other fluids during procedures. This technology not only enhances patient safety but also contributes to improved outcomes, underscoring the vital role that vacuum pumps play in shaping our daily life and health.

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

Vacuum pumps play a crucial role in various applications, from food packaging to industrial processes. This chart displays the average usage of vacuum pumps across different sectors, highlighting their importance in everyday tasks.

Key Factors in Choosing the Right Vacuum Pump for Your Needs

When selecting a vacuum pump for everyday use, several key factors must be considered to ensure it meets your specific needs. Firstly, the type of application plays a crucial role. For instance, if you're looking to use the pump for food storage, a chamber vacuum sealer may be ideal, as it removes air while allowing for liquid retention. Conversely, for automotive maintenance tasks, a rotary vane pump might be more suitable due to its ability to handle higher volumes of air.

When selecting a vacuum pump for everyday use, several key factors must be considered to ensure it meets your specific needs. Firstly, the type of application plays a crucial role. For instance, if you're looking to use the pump for food storage, a chamber vacuum sealer may be ideal, as it removes air while allowing for liquid retention. Conversely, for automotive maintenance tasks, a rotary vane pump might be more suitable due to its ability to handle higher volumes of air.

Another important aspect to consider is the pump's capacity and performance. Evaluating the flow rate and ultimate vacuum level is essential, as these specifications directly affect efficiency and time needed to achieve desired vacuum levels. Additionally, the noise level and portability of the pump can impact user experience—features like a quieter motor or compact design may be preferential for home use. Lastly, assessing energy efficiency not only helps reduce operational costs but also contributes to sustainable practices in everyday applications.

Understanding Different Types of Vacuum Pumps: A Comprehensive Overview

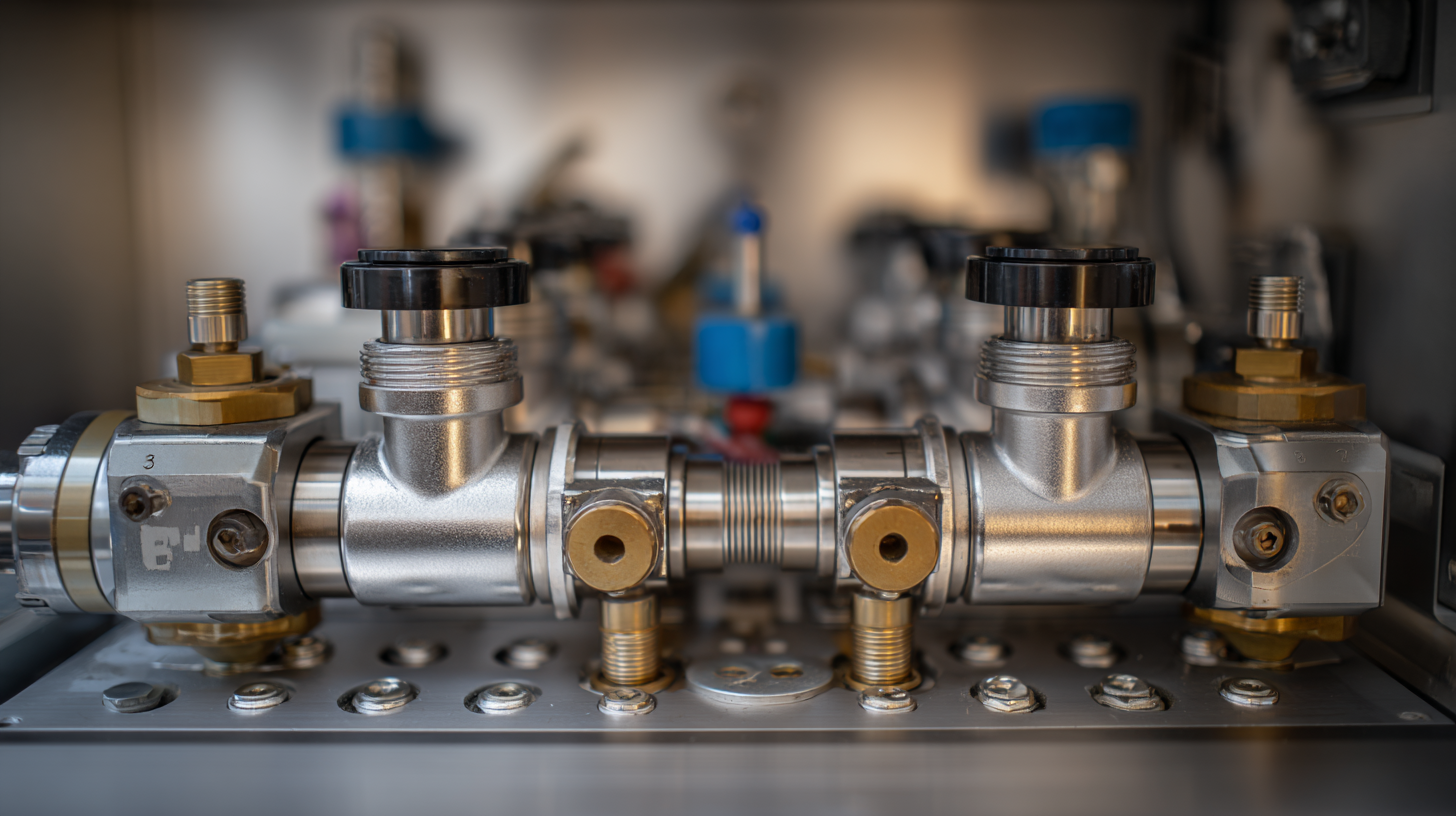

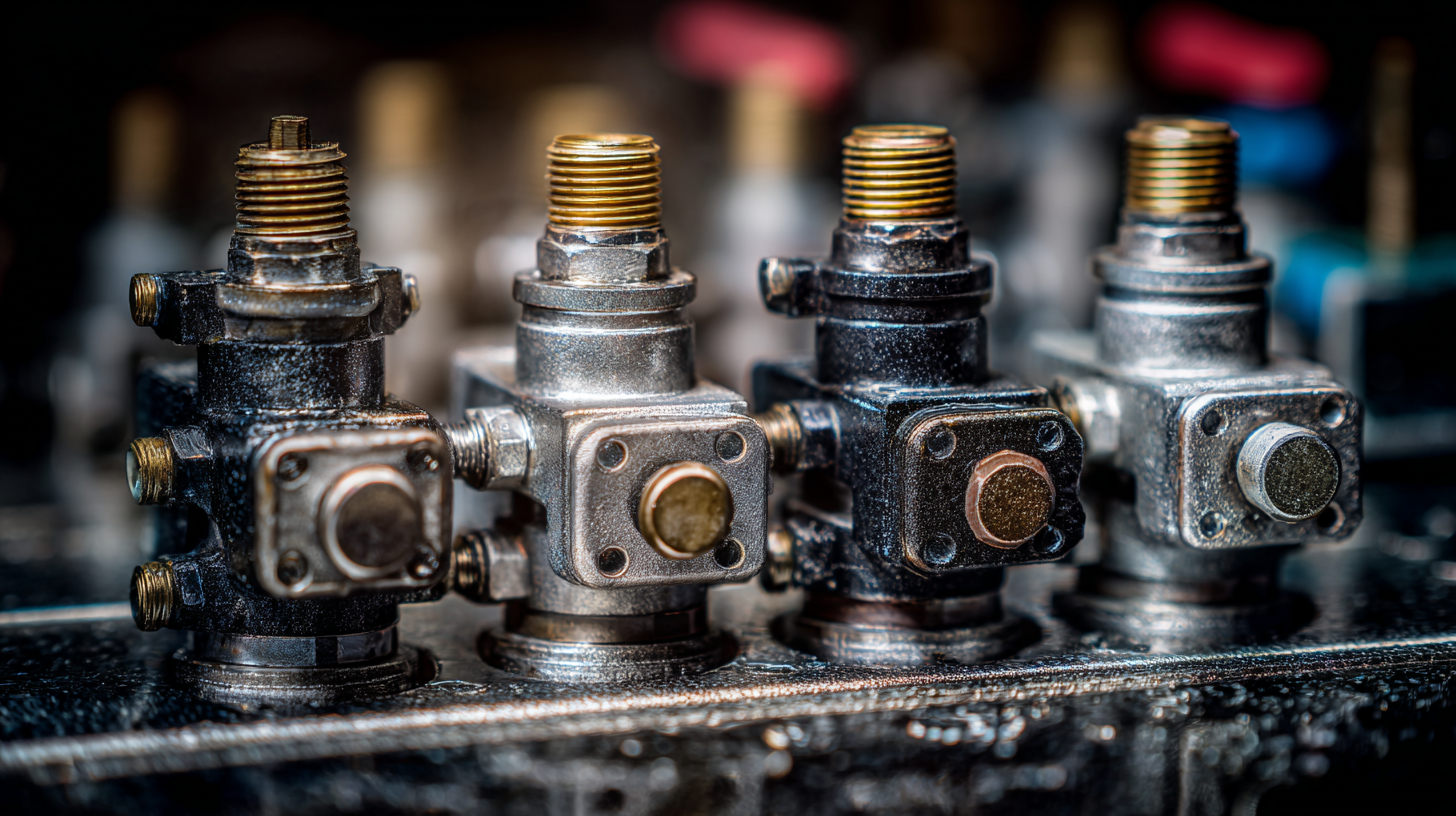

Vacuum pumps are essential tools in various industries, from food packaging to pharmaceuticals, and understanding the different types available can significantly impact efficiency and productivity. According to a report by Market Research Future, the global vacuum pump market is expected to reach approximately USD 5.5 billion by 2025, driven by increased demand in sectors such as electronics and automotive. The most common types include positive displacement pumps, momentum transfer pumps, and entrapment pumps, each serving unique applications based on their operational principles and efficiency.

Positive displacement pumps, such as rotary vane and diaphragm pumps, are widely used for their reliability and ease of maintenance. They work by trapping a fixed amount of gas and then forcing it out of the chamber, making them ideal for applications requiring consistent suction. On the other hand, momentum transfer pumps, including turbomolecular and diffusion pumps, are designed for creating extremely low pressures and are commonly utilized in vacuum systems for semiconductor manufacturing, where precision is paramount. With the right choice of vacuum pump, businesses can optimize their processes and reduce operational costs in an increasingly competitive marketplace.

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

| Type of Vacuum Pump | Application | Vacuum Range | Power Source | Pros | Cons |

|---|---|---|---|---|---|

| Rotary Vane Pump | Industrial and Laboratory | High to Medium Vacuum | Electric | Durable and reliable | Requires regular maintenance |

| Diaphragm Pump | Laboratory and Medical | Medium Vacuum | Electric or Pneumatic | Chemical resistant | Lower pumping speed |

| Scroll Pump | Semiconductor and Vacuum Coating | High Vacuum | Electric | Quiet operation | Higher initial cost |

| Side Channel Pump | Wastewater Treatment and Chemical Processing | Medium Vacuum | Electric | Robust and self-priming | Sensitive to solid particles |

| Turbo Molecular Pump | Research and High-Energy Physics | Ultra High Vacuum | Electric | Very high pumping speed | Requires a backing pump |

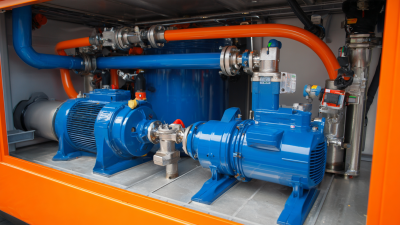

The Role of Vacuum Pumps in Enhancing Efficiency Across Industries

Vacuum pumps play a crucial role in enhancing efficiency across various industries by creating

a controlled environment that promotes optimal operation. In manufacturing, for instance, vacuum pumps are essential for processes such as

packaging and material handling,

where removing air from containers not only prolongs product shelf life but also reduces the risk of contamination. By maintaining a vacuum seal,

businesses can ensure their products remain fresh and safe, showcasing how vacuum technology directly contributes to operational efficiency and

product quality.

In the automotive sector, vacuum pumps are utilized in braking systems and

fuel handling, ensuring safety and performance. The ability to eliminate air and prevent vapor lock enhances

engine efficiency and responsiveness. Additionally, industries such as pharmaceuticals and

electronics rely on vacuum systems for critical processes, including

drying and degassing. Here, the absence of air and moisture can improve

product integrity and performance, demonstrating how vacuum pumps not only streamline production methods but also lead to better end products,

ultimately resulting in increased customer satisfaction and reduced waste.

Maintenance Tips and Best Practices for Optimizing Vacuum Pump Performance

When it comes to optimizing vacuum pump performance, understanding proper maintenance practices is crucial. Regular maintenance not only extends the lifespan of your pump but also ensures consistent performance and energy efficiency. According to a report by the Vacuum Pump Manufacturers Association, neglecting maintenance can lead to a 15-30% drop in pump efficiency over time. Therefore, routine checks, oil changes, and replacement of worn parts should be scheduled regularly, typically every 3 to 6 months depending on the frequency and nature of use.

In addition to routine maintenance, utilizing best practices during operation can significantly impact performance. Operating within the manufacturer's recommended ranges for pressure and temperature is key, as exceeding these limits can lead to premature wear or catastrophic failure. The American Society of Mechanical Engineers suggests that proper load management and minimizing unnecessary cycling can help in maintaining optimal performance levels. Furthermore, implementing a regular cleaning schedule for the pump's intake and exhaust ports can prevent contaminants from affecting the vacuum quality, ultimately ensuring efficient operation tailored to everyday needs.

Related Posts

-

The Essential Guide to Understanding Oil Vacuum Pumps and Their Applications in Industry

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications