- Eng

- Deu

- Fra

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

In today's industrial landscape, the efficiency of vacuum pumps plays a crucial role across various applications, from manufacturing to food preservation. Understanding the performance metrics of these vital devices not only enhances productivity but also reduces operational costs significantly. This article aims to explore the intricacies of vacuum pump technology, shedding light on how these pumps operate, their various applications in different sectors, and the key performance indicators that determine their effectiveness. By diving deep into the nuances of vacuum pump efficiency, we will present actionable tips and insights that can help businesses optimize their vacuum systems, ensuring they achieve maximum output with minimal energy consumption. Whether you are a seasoned engineer or a newcomer to the field, this exploration of vacuum pumps will equip you with the knowledge to make informed decisions about your equipment choices.

Key Takeaways: The effectiveness of vacuum pumps depends significantly on various factors including their design and operating conditions. Regular maintenance and performance monitoring are essential to maximize their efficiency.

Key Performance Indicators for Vacuum Pumps: Understanding Efficiency Metrics

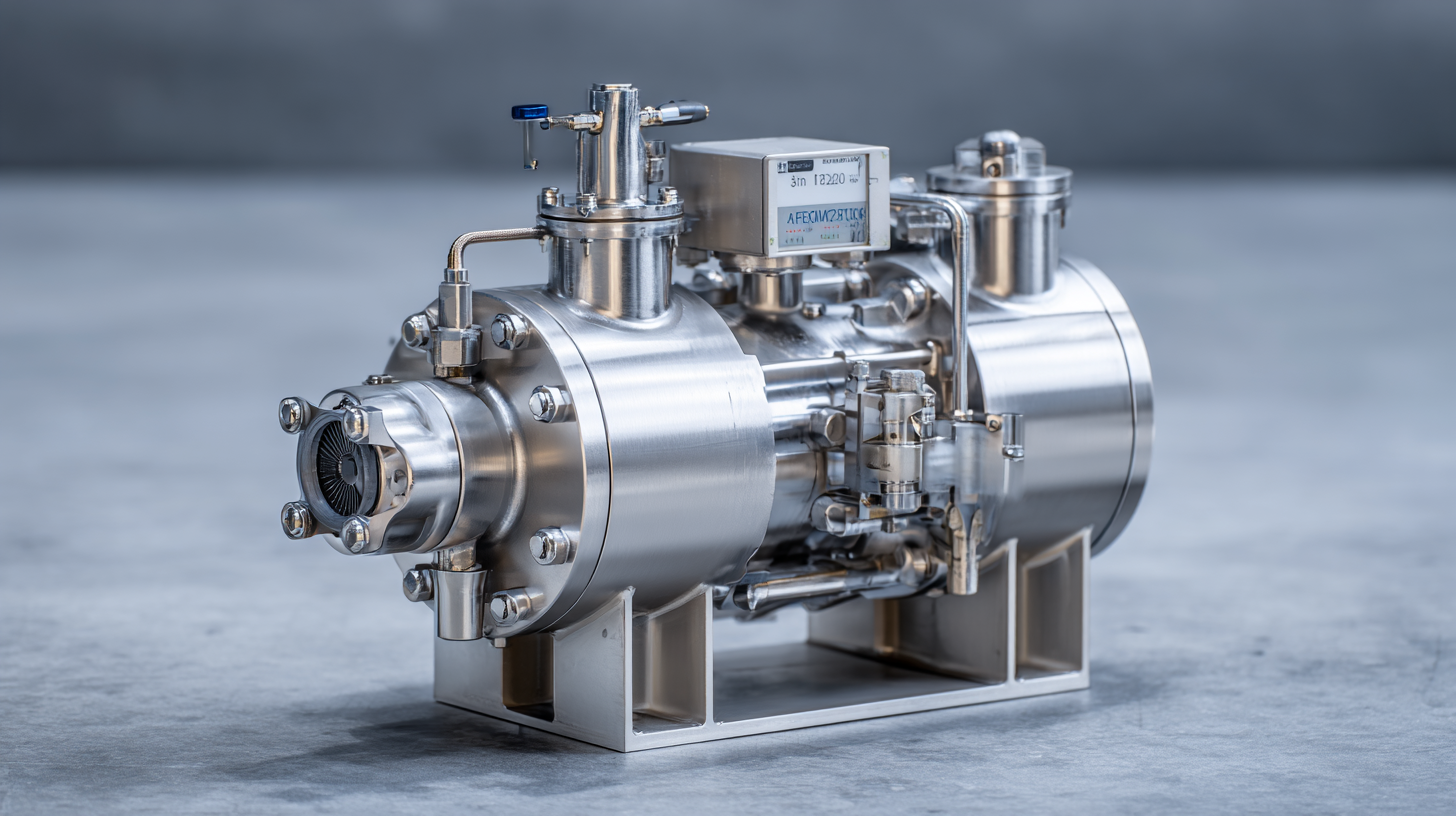

When assessing the efficiency of vacuum pumps, understanding key performance indicators (KPIs) is crucial. Efficiency metrics such as pumping speed, ultimate pressure, and energy consumption provide insight into the operational performance of vacuum systems. Pumping speed, typically measured in liters per second (L/s), indicates how quickly a pump can evacuate a chamber, making it essential for processes that require rapid vacuum generation. Meanwhile, the ultimate pressure reflects how low a pump can go, which is critical for applications needing a deep vacuum. Energy consumption, on the other hand, helps to understand the operational cost over time.

Tips for optimizing vacuum pump efficiency include ensuring proper maintenance, as a well-maintained pump operates more effectively. Regularly check for leaks in the vacuum system, since even small leaks can significantly affect performance. Additionally, consider the application requirements when selecting a vacuum pump—different processes may need specific types of pumps for optimal results. By aligning your equipment choice with your operational needs, you can improve both efficiency and cost-effectiveness.

It's also vital to monitor the performance metrics of your vacuum pump systematically. Implementing a routine check can help identify trends in performance, leading to proactive maintenance and adjustments. Keeping track of temperature, noise levels, and any unusual vibrations can signal underlying issues that could impact overall efficiency.

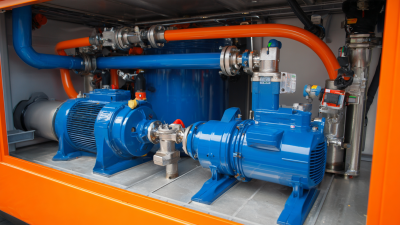

Common Applications of Vacuum Pumps Across Various Industries

Vacuum pumps play a crucial role in numerous industries by creating a vacuum that helps in various processes. In the medical field, for example, vacuum pumps are essential for suction devices used during surgeries and in maintaining sterile environments. In the food industry, they are employed in packaging processes to extend shelf life by removing air from packaging materials. Semiconductor manufacturing also heavily relies on vacuum pumps to create conducive environments for producing chips and other electronic components.

Tip: When selecting a vacuum pump for your application, consider the required pressure levels and flow rates, as different processes may demand specific performance metrics.

Tip: When selecting a vacuum pump for your application, consider the required pressure levels and flow rates, as different processes may demand specific performance metrics.

Another significant application is in the chemical and pharmaceutical sectors, where vacuum pumps assist in evaporation and distillation processes. By creating a low-pressure environment, these pumps enable quicker separation of substances and enhance reaction rates. Additionally, vacuum pumps are pivotal in research laboratories, where they provide the necessary conditions for experiments requiring low pressures.

Tip: Regular maintenance of vacuum pumps is vital to ensure longevity and optimal performance. Keeping the pumps clean and checking for leaks can help prevent inefficiencies in various industrial applications.

Tips for Selecting the Right Vacuum Pump for Your Specific Needs

When it comes to selecting the right vacuum pump for your specific needs, it's essential to consider various factors that influence both efficiency and performance. Whether you're working in a laboratory, an industrial setting, or even at home, understanding the intended application will guide you in making an informed decision. Different vacuum pumps are designed to handle various tasks, so identifying the nature of your work will help narrow down your options effectively.

Tips for Selecting the Right Vacuum Pump: First, determine the level of vacuum required for your application. This will influence the type of pump needed, as some models excel in achieving deep vacuums, while others may be better suited for moderate levels. Additionally, consider the volume of air or gas that needs to be evacuated. This will affect the pump's capacity and efficiency, making it crucial to match the pump size to your requirements.

Furthermore, pay attention to maintenance and operational costs. Some vacuum pumps may have lower upfront costs but higher long-term maintenance expenses. Weighing the initial investment against potential upkeep will help ensure you choose a model that fits your budget while still meeting performance expectations.

Maintenance Best Practices to Maximize Vacuum Pump Efficiency

Maintaining vacuum pumps at peak performance is crucial to their efficiency and longevity. Regular maintenance practices not only ensure optimal function but also extend the lifespan of the equipment. One essential aspect of pump maintenance is the routine inspection of seals and gaskets, which can wear out and lead to leaks if not monitored. Prompt replacement of these components can prevent significant drops in efficiency and potential damage to the pump.

Another best practice is to regularly check and change the lubrication, as it plays a vital role in reducing friction and wear. Dirty or contaminated oil can lead to overheating and operational failure, so implementing a schedule for oil changes is beneficial. Additionally, monitoring the operating temperature and pressure can provide valuable insights into the pump’s performance, allowing for timely intervention before problems escalate. By adhering to these maintenance strategies, operators can maximize the efficiency of their vacuum pumps, ensuring reliable performance across various applications.

Vacuum Pump Efficiency: Applications and Performance Metrics

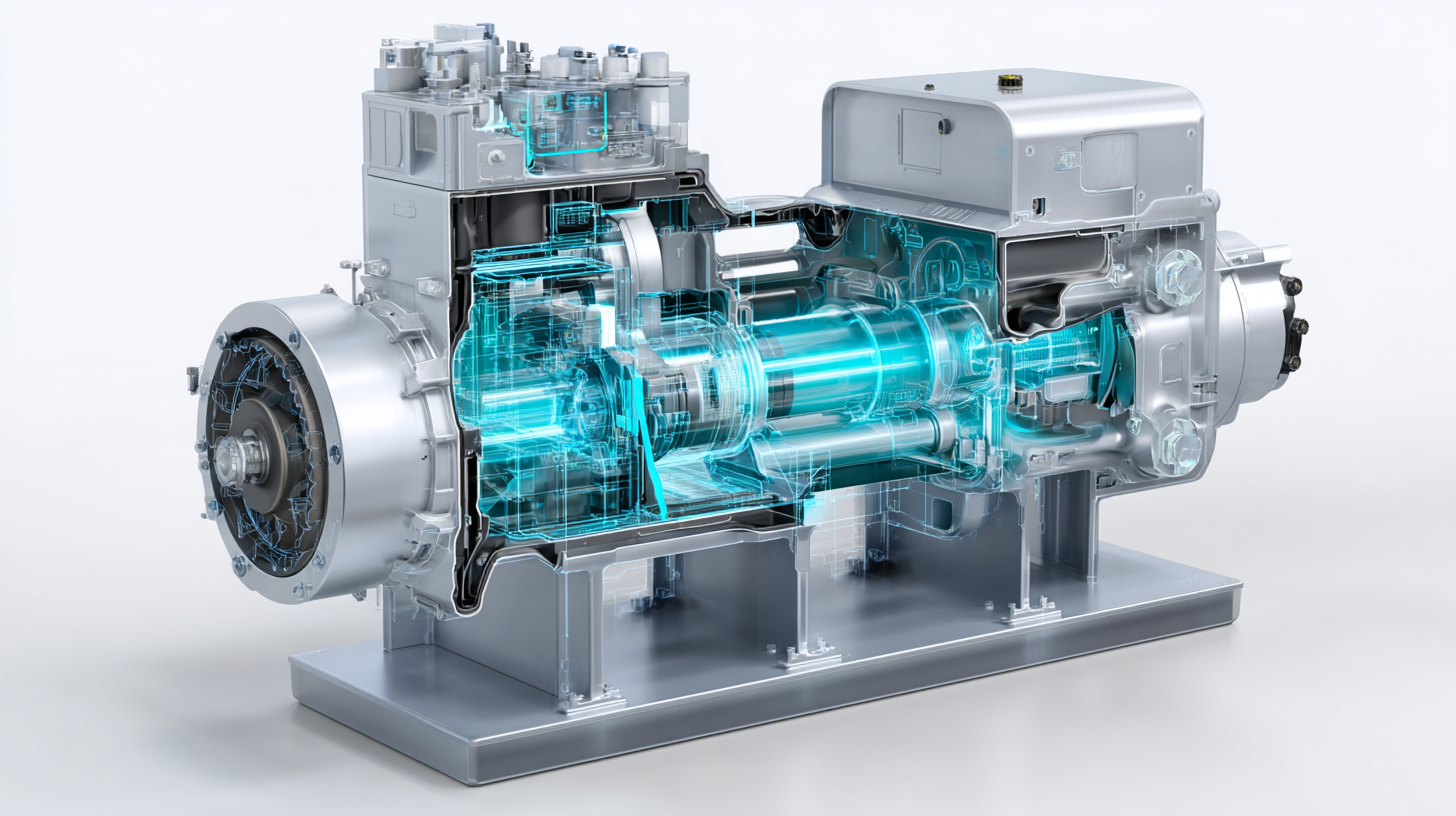

Innovations in Vacuum Pump Technology: Enhancing Performance and Sustainability

Recent innovations in vacuum pump technology have significantly enhanced both performance and sustainability, making these essential devices more efficient and environmentally friendly. Manufacturers are now focusing on advanced materials and designs that reduce energy consumption while improving pumping speed and reliability. For instance, the implementation of brushless DC motors has allowed for quieter operation and lower maintenance requirements, catering to industries ranging from healthcare to food processing.

Moreover, development in smart technology has further optimized vacuum pump systems. Integration with IoT (Internet of Things) allows for real-time monitoring and predictive maintenance, ensuring that pumps operate at peak efficiency while prolonging their lifespan. Such innovations contribute not only to cost savings for businesses but also minimize carbon footprints, aligning with global sustainability goals. As industries face increasing pressure to reduce waste and emissions, these advancements in vacuum pump technology are crucial in driving both environmental responsibility and operational excellence.

Related Posts

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

The Essential Guide to Understanding Oil Vacuum Pumps and Their Applications in Industry

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

The Impact of Vacuum Blowers on Reducing Environmental Noise Pollution

-

Exploring the Benefits of Tank Vacuum Systems: A Comprehensive Guide for Homeowners