- Eng

- Deu

- Fra

Understanding the Efficiency and Applications of Rotary Vane Vacuum Pumps in Modern Industries

The rotary vane vacuum pump stands as a pivotal technology in various modern industrial applications, notably in sectors such as pharmaceuticals, food packaging, and electronics manufacturing. With an industry report indicating that the global vacuum pump market is projected to reach $5.2 billion by 2026, the significance of efficient vacuum solutions cannot be overstated. The rotary vane vacuum pump, known for its reliability and simplicity, contributes to this growth by offering effective air displacement and maintaining consistent vacuum levels.

According to research by MarketsandMarkets, the increasing demand for automation in manufacturing processes has propelled the adoption of rotary vane vacuum pumps, particularly in high-precision applications where stability is crucial. This introduction sets the stage to explore the efficiency, operational advantages, and the expansive range of applications of rotary vane vacuum pumps in contemporary industries, underscoring their vital role in enhancing productivity and ensuring quality standards.

How Rotary Vane Vacuum Pumps Operate: A Comprehensive Overview

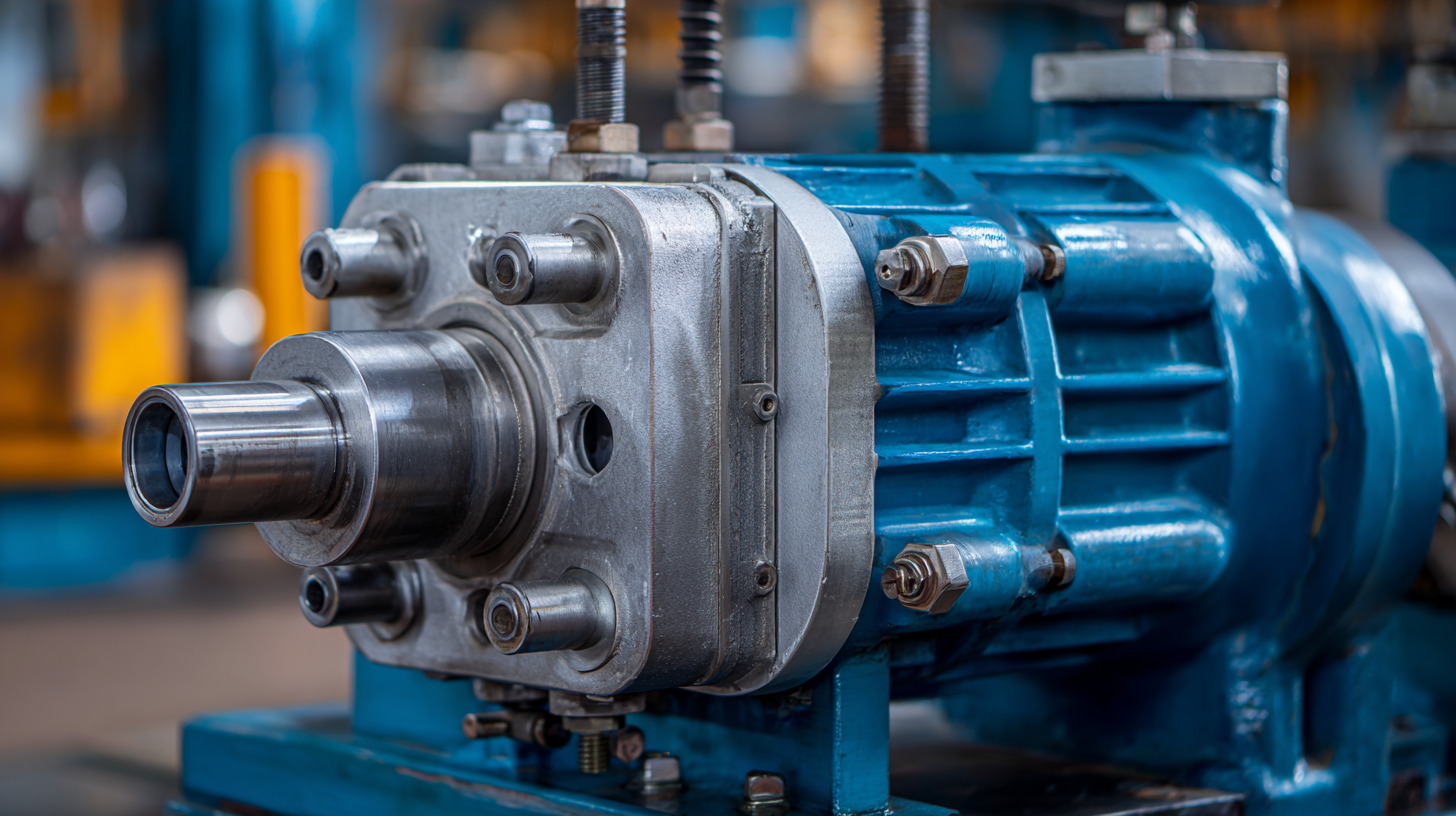

Rotary vane vacuum pumps operate on a straightforward yet effective principle that relies on rotating vanes to create a vacuum. These vanes slide in and out of a rotating rotor, creating a series of chambers that expand and shrink as the rotor turns. As the rotor spins, it traps air and pushes it through an exhaust port, thus generating a low-pressure environment. A recent industry report highlights that rotary vane vacuum pumps can achieve ultimate pressures as low as 0.5 mbar, making them suitable for a variety of applications where high levels of vacuum are essential.

In modern industries, these pumps are widely utilized across sectors such as food packaging, pharmaceutical manufacturing, and laboratory processes. Their ability to maintain consistent vacuum levels is critical for preserving product quality and ensuring operational efficiency. According to a market analysis by ResearchAndMarkets, the global rotary vane vacuum pump market is projected to grow at a CAGR of 5.4% from 2021 to 2026, driven by increasing automation in these industries. With their robust design and reliability, rotary vane vacuum pumps continue to play a pivotal role in enhancing process efficiencies and achieving optimal results in diverse industrial applications.

Key Advantages of Rotary Vane Vacuum Pumps in Industrial Applications

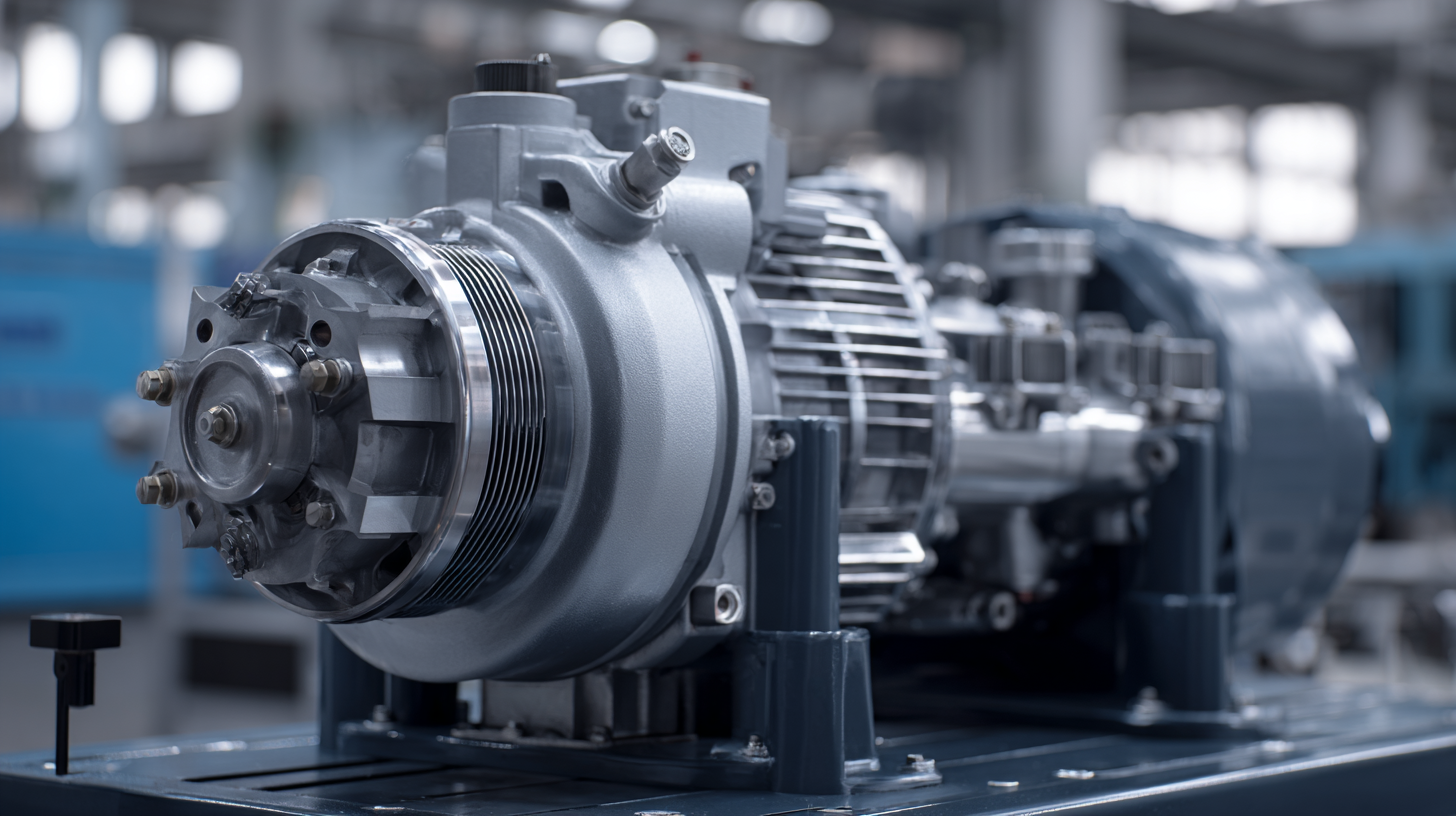

Rotary vane vacuum pumps have gained significant attention in modern industries due to their remarkable efficiency and versatile applications. One of the key advantages of these pumps is their ability to maintain a consistent vacuum level, which is crucial for processes that require precise control of atmospheric conditions. This reliability makes them ideal for use in sectors such as food packaging, pharmaceuticals, and electronics, where even minor fluctuations in vacuum pressure can lead to product quality issues.

Another compelling benefit of rotary vane vacuum pumps is their relatively low maintenance requirements. Unlike other types of vacuum pumps, rotary vane designs feature fewer moving parts, reducing wear and tear over time. This aspect not only extends the lifespan of the device but also minimizes downtime for repairs, ensuring a smoother and more efficient production process. Furthermore, their compact design allows for easier integration into existing systems, making them an attractive choice for industries looking to optimize their operations without significant modifications.

Common Industries Utilizing Rotary Vane Vacuum Technology

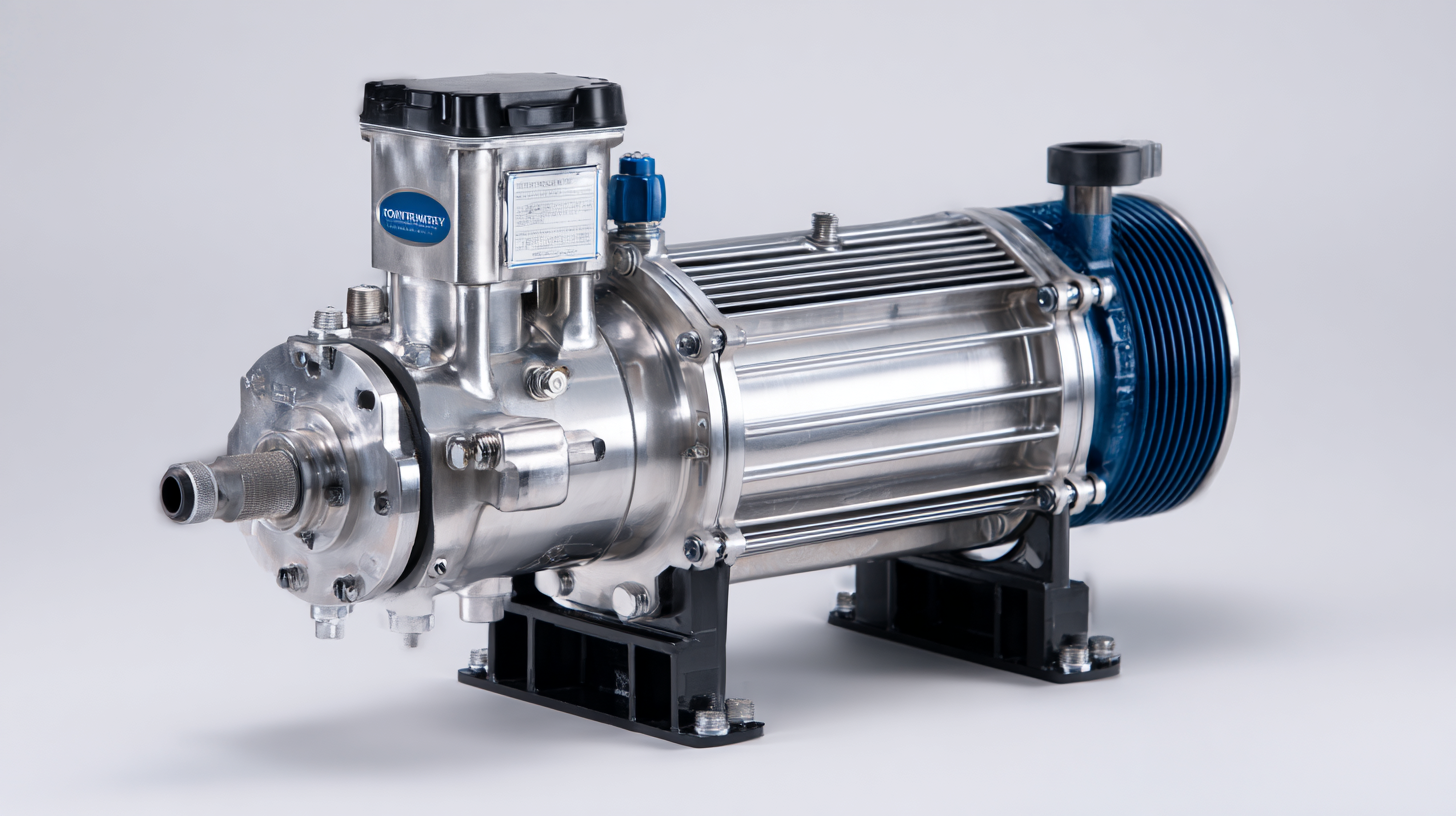

Rotary vane vacuum pumps have become indispensable across various industries due to their reliability and efficiency in creating vacuum conditions. These pumps operate on a simple mechanism, utilizing rotating vanes within a chamber to compress and exhaust air, making them ideal for applications requiring controlled environments. One of the primary industries leveraging this technology is the food and packaging sector. Here, rotary vane vacuum pumps are instrumental in preserving food quality by removing air during packaging, thus extending shelf life and preventing spoilage.

In the pharmaceuticals and biotechnology fields, the need for stringent vacuum levels is critical. Rotary vane vacuum pumps support various processes, including lyophilization and laboratory vacuum filtration. Their ability to maintain consistent vacuum levels contributes to the efficacy of drug formulations and ensures high-quality production standards. Furthermore, the automotive industry applies rotary vane pumps for tasks such as brake bleeding and fuel system testing, showcasing their versatility and essential role in enhancing production efficiency and safety in modern manufacturing processes.

Maintenance Best Practices for Maximizing Performance of Rotary Vane Pumps

Proper maintenance of rotary vane vacuum pumps is essential for maximizing their performance and ensuring long operational life. According to a report from the International Vacuum Equipment Association, regular maintenance can enhance pump efficiency by up to 30%, ultimately reducing operational costs for industries relying on vacuum technology. Key practices include monitoring oil levels and ensuring that oil quality is maintained, as contaminated oil can lead to overheating and increased wear on the vanes.

Additionally, regular inspections for wear and tear on the vanes and seals, combined with timely replacements, can prevent significant drop-offs in performance. The American Society for Testing and Materials recommends check-ups every 500 operating hours to maintain optimal function. By adhering to these maintenance schedules and employing best practices—such as keeping the pump clean and avoiding overloading—the reliability of rotary vane pumps can be assured, significantly enhancing productivity in various applications from food packaging to pharmaceuticals.

Emerging Trends and Innovations in Rotary Vane Vacuum Pump Technologies

Recent advancements in rotary vane vacuum pump technologies have significantly transformed their efficiency and utility across various industries. According to a report by MarketsandMarkets, the global vacuum pump market is projected to reach USD 6.94 billion by 2025, with rotary vane pumps gaining a notable share due to their reliability and performance. Innovations such as improved lubrication systems and the introduction of variable speed drives have not only increased energy efficiency but also enhanced operational flexibility, making these pumps suitable for diverse applications ranging from pharmaceuticals to food processing.

Emerging trends also highlight the integration of IoT and smart technologies in rotary vane vacuum pumps. These developments enable predictive maintenance, which can significantly reduce downtime and maintenance costs. A study from Allied Market Research indicates that implementing IoT in industrial equipment can lead to potential savings of around 10-20% in operational costs. Additionally, advancements in materials science have led to the creation of more durable vanes, which extend the lifespan of pumps while maintaining consistent performance, thereby meeting the stringent requirements of modern manufacturing and processing environments.

Efficiency Comparison of Rotary Vane Vacuum Pumps by Application

Related Posts

-

The Impact of Vacuum Blowers on Reducing Environmental Noise Pollution

-

Exploring the Benefits of Tank Vacuum Systems: A Comprehensive Guide for Homeowners

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

The Essential Guide to Understanding Oil Vacuum Pumps and Their Applications in Industry

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications