- Eng

- Deu

- Fra

How to Choose the Right Vacuum Blower Pump for Your Needs

Choosing the right vacuum blower pump can significantly impact the efficiency of your operations, whether in industrial applications or specialized projects. As noted by industry expert Dr. Henry Lang, "The selection of a vacuum blower pump should be driven by your specific needs and the environment in which it operates." Understanding the unique requirements of your application is essential in making an informed choice that meets both performance and reliability standards.

There are various factors one must consider when selecting a vacuum blower pump, including the required vacuum level, flow rate, and the characteristics of the materials being handled. For example, heavier materials may necessitate a different type of pump compared to lighter or more fragile substances. Additionally, compatibility with existing systems and energy efficiency are also vital considerations that could influence long-term operational costs and sustainability.

In a market saturated with options, having a clear understanding of these factors can guide you toward the right vacuum blower pump that fits your needs. By carefully evaluating your requirements and the capabilities of potential pumps, you can ensure optimal performance and longevity in your processes.

Understanding the Different Types of Vacuum Blower Pumps Available

When selecting a vacuum blower pump, it is essential to understand the different types available to determine which best suits your requirements. There are primarily three categories of vacuum blower pumps: positive displacement pumps, kinetic pumps, and liquid ring pumps. Each type operates on distinct principles and is optimized for specific applications, making the decision process crucial for efficiency and effectiveness.

Positive displacement pumps function by trapping a fixed volume of gas and then displacing it completely, making them ideal for applications requiring a strong vacuum with high reliability. On the other hand, kinetic pumps utilize high-speed impellers to move gas, providing a continuous flow and being particularly well-suited for applications involving low pressure or high-speed air movement. Lastly, liquid ring pumps employ a rotating mechanism with a liquid seal, making them highly effective in handling gases that contain moisture or particulate matter, which can be challenging for other types.

By understanding these different types and their operational mechanics, users can make an informed choice that aligns with their specific needs, whether it be for industrial, laboratory, or commercial applications. Proper selection ensures optimal performance and longevity of the equipment, thereby enhancing overall operational efficiency.

Vacuum Blower Pump Types Comparison

This chart compares different types of vacuum blower pumps based on their maximum vacuum levels in mbar. Each pump type offers different applications and performance characteristics, making it essential to choose the right one for your specific needs.

Identifying Your Specific Needs for Vacuum Blower Pump Applications

When selecting the right vacuum blower pump for your applications, it’s essential to first identify your specific needs. Start by considering the type of materials you will be handling and the required pressure levels for optimal performance. Different materials may require varying levels of vacuum, so understanding the properties of the substances involved can significantly influence your choice. For instance, if you are working with delicate materials, a pump that can achieve a gentle vacuum without causing damage is crucial.

Additionally, evaluate the operational environment where the vacuum blower pump will be used. Factors such as temperature, humidity, and the presence of dust or other particulates can affect the pump's efficiency and lifespan. For harsh environments, it may be necessary to select a model constructed with durable materials that can withstand adverse conditions. Furthermore, consider the volume of air that needs to be moved. Higher-capacity pumps may be required for larger applications, while smaller, more compact models might be sufficient for light-duty tasks. Taking the time to assess these specific needs will ensure that you select a vacuum blower pump that is best suited for your operations.

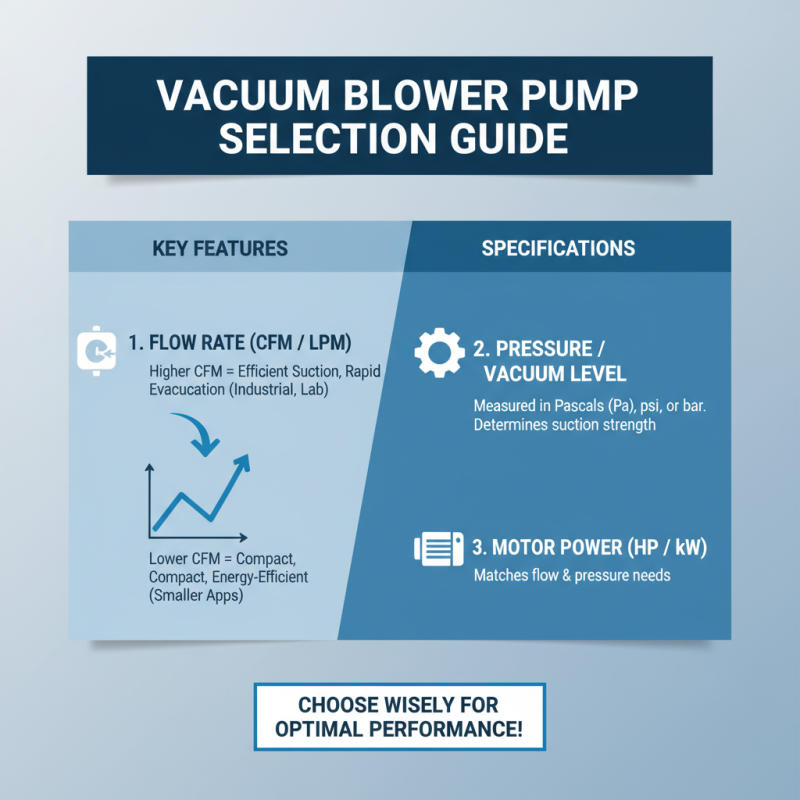

Evaluating Key Features and Specifications of Vacuum Blower Pumps

When selecting a vacuum blower pump, understanding the key features and specifications is crucial to ensuring that you choose a model that meets your specific needs. One of the primary factors to consider is the pump's flow rate, often measured in cubic feet per minute (CFM) or liters per minute (LPM). A higher flow rate typically indicates more efficient suction and is essential for applications requiring rapid evacuation, such as in industrial processes or laboratory environments. Conversely, for smaller applications, a lower flow rate might suffice, allowing for a more compact and energy-efficient solution.

Another important specification is the vacuum level, which indicates how much air the pump can remove from a sealed environment. This is typically measured in inches of mercury (Hg) or millibar. Depending on your application, you may require a pump that can achieve deep vacuum levels, essential for tasks like freeze-drying or certain manufacturing processes. Additionally, consider the pump's noise level, especially if it will be operating in a noise-sensitive environment. Efficiency, durability, and maintenance requirements are also key aspects to evaluate, as these factors can significantly affect the long-term performance and reliability of your chosen vacuum blower pump.

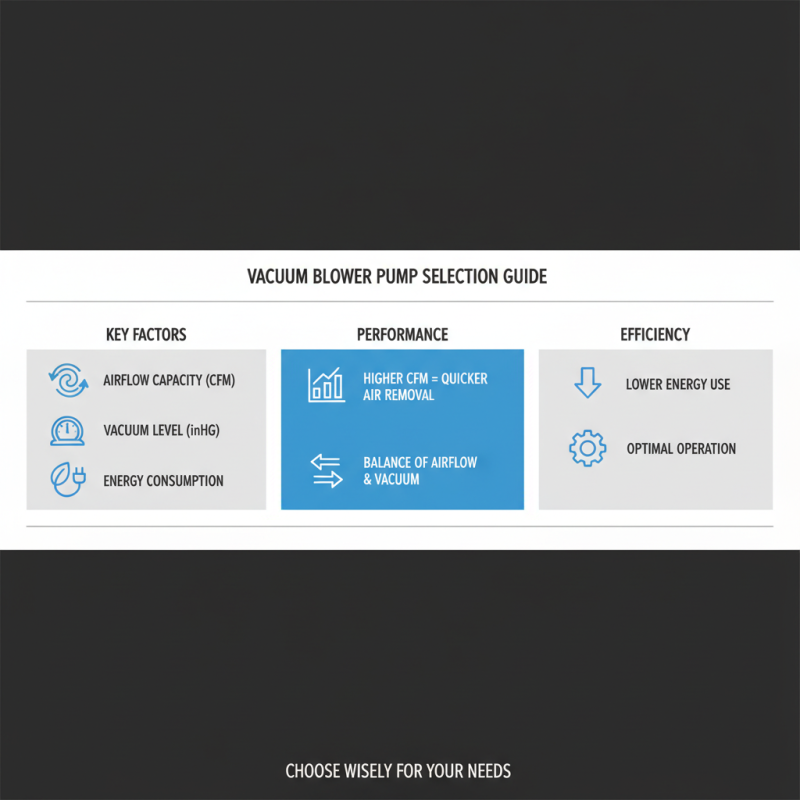

Comparing Performance and Efficiency Ratings of Various Models

When selecting a vacuum blower pump, it's essential to compare the performance and efficiency ratings of various models. Key factors to consider include the pump's airflow capacity, vacuum level, and energy consumption. Airflow capacity, typically measured in cubic feet per minute (CFM), indicates how much air the pump can move efficiently. A higher CFM means quicker removal of air, which may be crucial for certain applications. Additionally, the vacuum level, often measured in inches of mercury (Hg), tells you how effectively the pump can create a vacuum. Opt for models that offer the best balance between airflow and vacuum level for your specific needs.

Efficiency ratings also play a critical role in selecting the right pump. Look for energy-efficient models that consume less power while delivering optimal performance. This not only reduces operational costs but also lessens the environmental impact. Ensure that the efficiency rating is backed by appropriate testing standards, which can help inform your decision-making process.

Tips: Before finalizing your choice, consider the noise level of the pump, especially if it will be used in noise-sensitive environments. Additionally, check user reviews for insights about reliability and maintenance needs. Investing time in understanding these aspects can lead to better long-term satisfaction with your vacuum blower pump.

Considering Budget Constraints and Long-Term Maintenance Costs

When selecting a vacuum blower pump, it's crucial to consider not only the initial purchase price but also the long-term maintenance costs that can impact your overall budget. A lower-priced pump may seem appealing at first, but if it requires frequent repairs or replacement parts, it can end up costing more in the long run. Thus, investing in a

quality pump

from the outset can result in greater savings and efficiency over time.

Tip: Always check the warranty and service agreements provided with the pump. A comprehensive warranty can safeguard you against unexpected expenses and offer peace of mind regarding the product’s longevity. Additionally, look for pumps that are designed for easy maintenance, as this can drastically reduce downtime and repair costs.

Another vital aspect to consider is the

energy efficiency

of the pump. An energy-efficient model may have a higher upfront cost, but it can lead to significant savings on energy bills and reduced operational costs over its lifespan. Be sure to evaluate the operating costs involved, including electricity consumption and periodic maintenance checks, to make a fully informed decision.

Tip: Research and compare the energy ratings of different models. Choosing a pump with a higher efficiency rating can lead to lower utility expenses while also contributing to a more sustainable operation.

Related Posts

-

10 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

Maximizing Efficiency: The Impact of Industrial Vacuum Blowers on Energy Consumption in Manufacturing

-

2025 Top 5 Vacuum Blower Pumps to Boost Your Industrial Efficiency

-

What is a Vacuum Blower Pump and How Does It Work in Industry

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems