- Eng

- Deu

- Fra

2026 How to Choose the Right Rotary Vane Vacuum Pump for Your Needs?

Choosing the right rotary vane vacuum pump can be a daunting task. It requires knowledge and understanding of specific needs. Dr. John Stevens, an industry expert, once said, “Selecting the perfect rotary vane vacuum pump is crucial to ensure efficiency and reliability.”

When evaluating options, consider your unique applications. Different models offer various capacities and performance features. A rotary vane vacuum pump's efficiency strongly influences operational costs. This makes it essential to match pump specifications with your requirements.

It can be easy to overlook the important aspects in this selection process. Take the time to assess your workflow and pressures. Make sure the pump fits seamlessly into your setup. Some users tend to rush their decisions, resulting in mismatches that lead to poor performance. Reflect on your choices, and choose wisely.

Understanding the Basics of Rotary Vane Vacuum Pumps

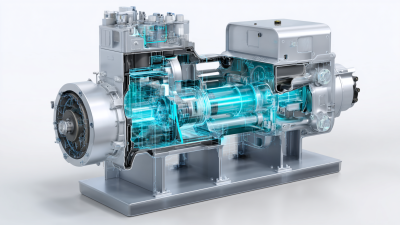

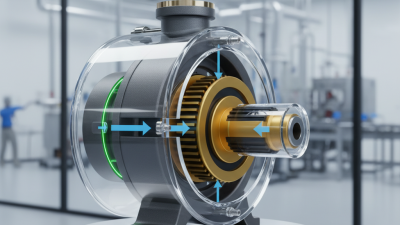

Rotary vane vacuum pumps are essential tools in many industrial applications. They work by trapping air between vanes and a rotating rotor. This creates a vacuum, enabling processes in manufacturing, packaging, and more. According to a recent industry report, the global rotary vane pump market is projected to grow by 5% annually. This growth indicates the rising demand for efficient vacuum solutions.

Understanding the basics is crucial when selecting the right pump. A standard rotary vane vacuum pump operates effectively between pressures of 1000 mbar to nearly zero. This range meets the needs of various applications, from food preservation to medical equipment. However, these pumps can experience wear over time, affecting their performance. It's vital to consider the maintenance frequency and replace vanes as needed.

For optimal efficiency, users should assess their specific requirements. Factors such as required vacuum level, flow rate, and space constraints play a role. Some applications may need continuous operation, while others might not. Each situation presents a unique challenge, and overlooking these details can lead to suboptimal performance. Users might find themselves re-evaluating their choices after experiencing issues.

Identifying Your Specific Application Requirements

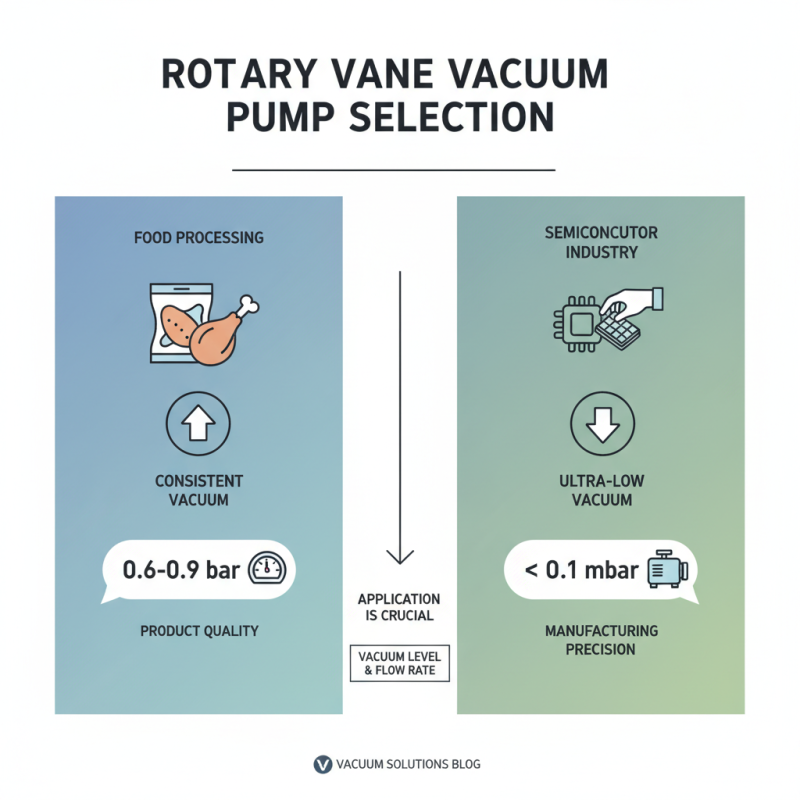

When selecting a rotary vane vacuum pump, understanding your specific application is crucial. Different industries have unique requirements for vacuum levels, flow rates, and efficiency. For instance, in the food processing sector, maintaining a consistent vacuum is vital for preserving product quality. The ideal vacuum level for food preservation typically hovers around 0.6-0.9 bar. On the other hand, in the semiconductor industry, the demands can require vacuum levels lower than 0.1 mbar, which constitutes a significant deviation in specifications.

Tip: Define your application’s vacuum level and flow rate requirements clearly. This will narrow down the choices significantly. Understanding if you need intermittent or continuous operation can also guide your selection. A report by Vacuum Solutions Inc. highlights that 30% of users fail to specify their operational needs, leading to suboptimal choices.

Also, consider maintenance needs. Some pumps require regular oil changes. Regular maintenance is critical to ensure longevity and efficiency. Meanwhile, users often underestimate the importance of energy efficiency. A study found that energy costs can account for nearly 80% of a pump's lifetime cost.

Tip: Research energy-efficient models. They may have a higher upfront cost but can save money long-term. Reflecting on these factors will help in making an informed decision tailored to your operational requirements.

Evaluating Key Features of Rotary Vane Vacuum Pumps

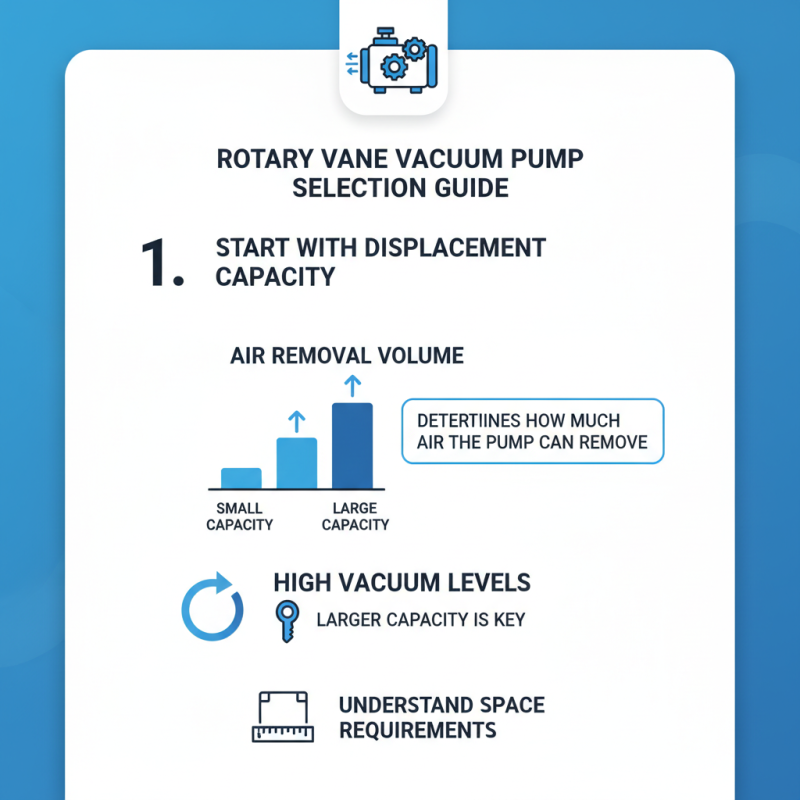

When evaluating rotary vane vacuum pumps, start with displacement capacity. It determines how much air the pump can remove. If your application requires high vacuum levels, a pump with a larger capacity is key. Understand how much space you need to cover.

Next, consider the noise level. Some pumps can be surprisingly loud. You may need to wear ear protection in certain settings. This factor could affect the work environment. If noise is an issue, look for models designed for quieter operation.

Also, think about maintenance requirements. Some pumps need regular oil changes. This can be a hassle. Others may require less frequent servicing. Choosing a pump that fits your maintenance schedule is crucial. Reflect on your specific needs and workload before making a decision.

Comparing Performance Metrics and Specifications

When selecting a rotary vane vacuum pump, understanding performance metrics is essential. Key specifications include ultimate vacuum, pumping speed, and noise levels. The ultimate vacuum indicates how low the pressure can go, typically measured in millibar (mbar). For most applications, a vacuum between 1 mbar and 10 mbar works well.

Pumping speed is equally significant. It shows how efficiently the pump can remove gas, usually measured in liters per minute (L/min). A low L/min rate may not meet your needs, especially in high-demand environments. Industry data suggests looking for a pump with a minimum of 50 L/min for robust applications.

Tip: Always check the noise level, especially if the pump will be used in a collaborative workspace. Noise levels above 70 dB can be disruptive, so quieter models may be preferable.

Attachments and maintenance schedules matter too. Different setups affect pump longevity and performance. Regular maintenance can extend the lifespan and ensure constant performance. Equipment often requires oil changes or filter replacements, which can be overlooked.

Tip: Consider the pump's size and weight. Larger models may offer higher performance but could be impractical in tight spaces.

Every application is unique. Reflect on your specific requirements before making a choice.

Comparison of Rotary Vane Vacuum Pumps Performance Metrics

Considering Maintenance and Support Options

When selecting a rotary vane vacuum pump, maintenance and support options are crucial. Your chosen pump needs regular upkeep. A well-maintained pump works better and lasts longer. Consider the availability of service centers. They should be easy to reach and have knowledgeable staff.

Tips: Check the warranty details. A good warranty often indicates reliable customer support. Ask about yearly maintenance plans. Some manufacturers offer packages that can save you money long-term.

Be cautious here. Not all pumps are easy to maintain. Some designs require specialized tools, which can be frustrating. Simplicity is key. Choose a pump that allows easy access to parts for maintenance. You will thank yourself later when service calls become rare.

Related Posts

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

What is an Oil Vacuum Pump and How Does it Work for Efficient Operations

-

What is a Vacuum Blower Pump and How Does It Work in Industry

-

Top 10 Benefits of Using Rotary Vane Vacuum Pumps for Your Applications