- Eng

- Deu

- Fra

How to Choose the Right Vacuum Oil for Your Equipment?

When selecting the right vacuum oil for your equipment, it’s important to understand its role. Vacuum oil is essential for maintaining optimal performance. It helps reduce wear and tear on machinery. The correct type ensures better efficiency and longevity.

Choosing vacuum oil can be daunting. Different applications require different formulations. Factors like viscosity, thermal stability, and pump type play critical roles. A mismatch can lead to problems. You might notice increased friction or overheating. These issues could halt operations.

Understanding your equipment's specific needs is vital. Consider the operating conditions and manufacturer recommendations. Keep quality in mind. Low-quality oils can result in poor performance. Sometimes, less is not more. Inadequate selections can lead to costly repairs and downtime. Evaluate your choices carefully.

Understanding Vacuum Oils: Essential Properties and Functions

Choosing the right vacuum oil is crucial for optimal equipment performance. Vacuum oils serve several essential functions, including lubrication, sealing, and reducing vapor pressure. The correct oil can enhance the efficiency of the vacuum system and prolong equipment life. Industry reports indicate that improper oil selection can lead to up to a 30% decrease in equipment efficiency.

Understanding the essential properties of vacuum oils is vital. Key characteristics include viscosity, thermal stability, and chemical compatibility. For example, oils with higher viscosity can provide better lubrication but may lead to higher heat generation. A report by the International Vacuum Society highlights that thermal stability is critical; oils that break down at high temperatures can introduce contaminants into the system.

Moreover, the right vacuum oil should meet specific performance benchmarks. Research suggests that optimal leakage rates can be achieved with oils designed for low vapor pressure. However, many users overlook these specifications. Some equipment failures are directly linked to inadequate oil choices, leading to costly downtime. Reflecting on these factors can guide users to make informed decisions.

Identifying Equipment Needs: Matching Vacuum Oils to Your Machinery

Choosing the right vacuum oil can seem challenging. It is essential to know your equipment needs. Different machines operate under varying conditions. High temperatures might demand specific oil types. Each piece of machinery has its own requirements. Understanding these needs is the first step.

When it comes to vacuum oils, viscosity is crucial. Oil that is too thick can hinder performance. Conversely, oil that is too thin may not provide adequate lubrication. Always consult the machinery manual for guidance. Consider the operating environment too. Dusty or humid conditions will affect oil choice. Regularly examining oil levels is a good practice. It helps in determining oil longevity.

Remember, trial and error is a part of the process. Each attempt can teach valuable lessons. You may need to adjust your choices. Mistakes with oil can be costly. Therefore, take your time to assess. Finding the right match will enhance your machine's life.

How to Choose the Right Vacuum Oil for Your Equipment?

| Equipment Type | Optimal Vacuum Oil Type | Viscosity (cSt @ 40°C) | Operating Temperature (°C) | Applications |

|---|---|---|---|---|

| Rotary Vane Pumps | Mineral Oil | 68 | -10 to 60 | General vacuum applications |

| Dry Vacuum Pumps | Synthetic Oil | 32 | 0 to 70 | Food processing, pharmaceuticals |

| Liquid Ring Pumps | Water-based Oil | - | -5 to 80 | Chemical processing |

| Scroll Vacuum Pumps | Non-oil Based | - | -20 to 50 | Semiconductor manufacturing |

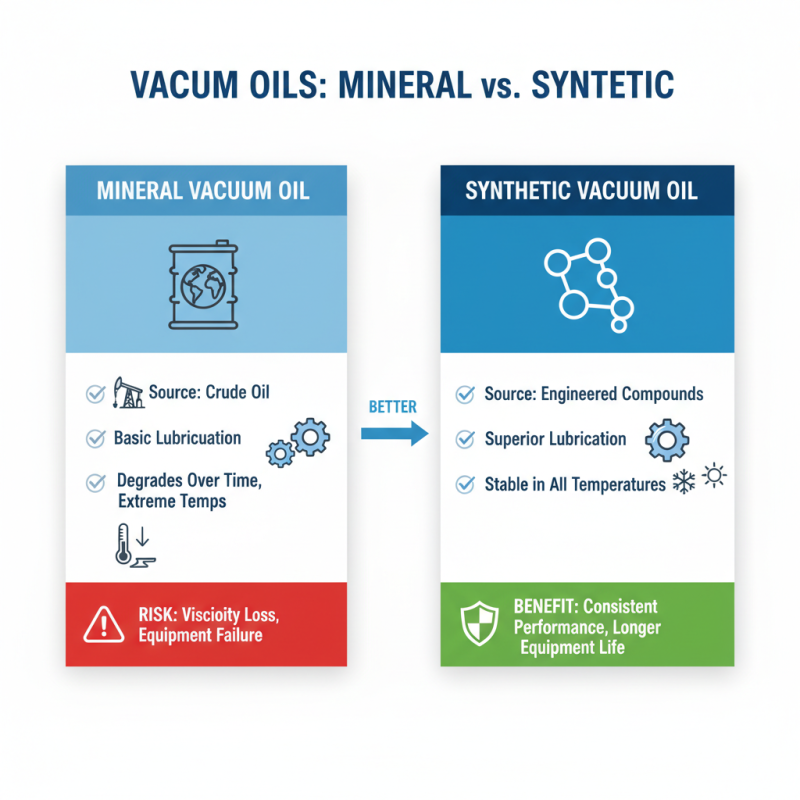

Types of Vacuum Oils: Mineral vs. Synthetic Options Explained

When choosing vacuum oils for equipment, understanding the differences between mineral and synthetic options is crucial. Mineral oils are derived from crude oil. They provide basic lubrication and have been widely used across various industries. However, their performance can degrade over time, especially in extreme temperatures. Reports indicate that mineral oils may lose viscosity, leading to potential equipment failure.

On the other hand, synthetic oils offer enhanced characteristics. They are designed to withstand higher temperatures and resist oxidation. According to industry studies, synthetic vacuum oils can improve pump reliability by up to 30%. This resilience can result in less downtime and lower maintenance costs. However, synthetic oils often come with a higher price tag. It's essential to weigh your operational needs against the potential benefits.

**Tip:** Always check compatibility with your equipment. Using the wrong oil type can cause significant damage over time. Familiarize yourself with your equipment’s specifications before making a choice.

**Tip:** Regularly monitor oil quality. Oil degradation can occur faster than expected, especially in high-demand environments. Keeping an eye on oil condition can prevent unexpected breakdowns.

Factors to Consider: Viscosity, Thermal Stability, and More

When selecting vacuum oil, viscosity is a key factor. It refers to the oil's thickness and flow characteristics. Higher viscosity oils provide better film strength but may lead to inefficient pumping. Lower viscosity oils can enhance pump performance but may compromise equipment protection. Finding the right balance is crucial. Monitor the specific operational temperature and maintain optimal viscosity for your system.

Thermal stability is another important consideration. Oils that break down at high temperatures can form deposits. This can cause wear and tear on your equipment. Look for oils that remain stable under extreme conditions. Checking the oil's thermal properties ensures your equipment runs smoothly.

Other factors like chemical compatibility should not be overlooked. Some oils may react with materials in your system, leading to damage. Testing a small sample can prevent costly mistakes. Remember, choosing the right vacuum oil is not just about technical specifications; it's also about the practical implications of your environment.

Vacuum Oil Properties Comparison

Best Practices for Maintenance: Handling and Storing Vacuum Oils

Proper handling and storage of vacuum oils is vital for equipment longevity. Contaminants can drastically affect oil performance. According to a study by the Vacuum Technology Association, 40% of vacuum system failures are due to improper oil management. The choice of storage containers should be specific and clean. Always use dedicated containers made for vacuum oils. Avoid using old cans that might introduce particles or contaminants.

When storing vacuum oils, keep them in a cool, dry place. Extreme temperatures can alter oil viscosity. Data from the International Society of Vacuum Science suggests that prolonged exposure to heat can reduce oil effectiveness by up to 30%. Also, ensure that containers are tightly sealed. An open container can lead to moisture absorption. Oil can absorb water from the air, leading to problems like emulsification and decreased performance.

Handling practices are equally important. Use gloves when dealing with oils to avoid contamination. Even the oils from our skin can affect oil quality. Train staff on the importance of oil storage and handling techniques. Regularly monitor the condition of stored oils. Discoloration or sediment can indicate degradation. Implementing these practices can help maintain optimum performance in your vacuum systems.

Related Posts

-

Exploring Vacuum Oil: Key Benefits and Industry Trends Influencing Machinery Performance

-

Unlocking the Secrets: How Vacuum Oil Enhances Industrial Efficiency and Equipment Longevity

-

What is Vacuum Oil and How it Benefits Industrial Applications

-

2025 Top Vacuum Oil Types: Key Benefits and Uses You Should Know

-

2025 How to Choose the Right Septic Pump for Your Home System

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use