- Eng

- Deu

- Fra

How to Choose the Right Oil Vacuum Pump for Your Needs in 2025

Choosing the right oil vacuum pump can be a daunting task, especially in 2025. With advancements in technology and a growing variety of options, the decision-making process becomes even more complex. Industry expert Emily Johnson, a leading figure in vacuum technology, emphasizes, "Understanding your specific needs is crucial for selecting an optimal oil vacuum pump."

There are many factors to consider. For instance, how often will you use the pump? Will it be for industrial applications or smaller tasks? Each scenario demands a different capacity and performance level. Potential buyers should pay close attention to the specifications. Not all oil vacuum pumps offer the same efficiency or durability.

We also must reflect on our choices. Sometimes, we prioritize price over quality, which can lead to dissatisfaction. Understanding the true application of the oil vacuum pump is essential. Evaluating customer reviews and seeking expert opinions can guide your purchase. The right pump can enhance productivity significantly, but the wrong choice can waste time and resources.

Understanding the Basics of Oil Vacuum Pumps and Their Applications

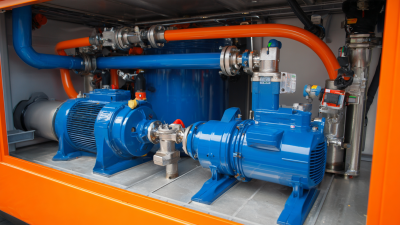

Oil vacuum pumps play a crucial role in various industries. They are essential for removing air and moisture from systems. This ensures optimal performance and longevity of your equipment. These pumps are widely used in HVAC, automotive, and manufacturing applications. Choosing the right one can be overwhelming. There are many options available, each designed for specific tasks.

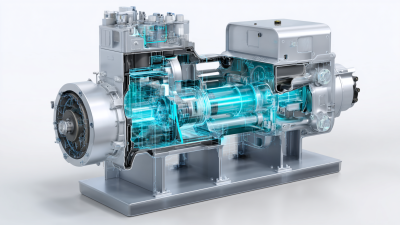

Understanding the basics of oil vacuum pumps is essential. These pumps use oil to create a vacuum, which enhances their efficiency. The oil lubricates the moving parts, reducing wear and tear. However, improper maintenance can lead to serious issues. Contaminated oil can hamper performance and shorten the pump's lifespan. It’s important to monitor oil quality regularly.

When selecting an oil vacuum pump, consider your specific needs. Different tasks may require different pump capacities. A small workshop might not need the same power as a large industrial facility. Overestimating your needs can lead to unnecessary expenses. On the other hand, underestimating can result in insufficient performance. Balancing these factors is key to making an informed decision.

Oil Vacuum Pumps: Performance vs. Applications

This bar chart illustrates the maximum vacuum capabilities of different types of oil vacuum pumps, including Rotary Vane, Diaphragm, Liquid Ring, and Scroll types. Each pump type serves distinct applications based on their vacuum performance.

Key Factors to Consider When Selecting an Oil Vacuum Pump

Choosing the right oil vacuum pump requires careful thought. Several key factors need consideration. The intended application drives specifications. Will it be used for heavy-duty tasks or lighter ones? Understanding your needs is crucial.

Consider the pump's capacity. It should match your requirements without oversizing. A bigger pump may waste energy. Now, look at the design of the pump. Compact models save space. However, they might not always handle larger volumes efficiently. Sometimes, a balance is necessary.

Maintenance is another factor. Some pumps require regular servicing, while others are more user-friendly. Think about ease of operation too. A complex interface can frustrate users. Evaluating these elements helps you make a better choice. Reflect on your long-term needs before deciding.

Evaluating the Technical Specifications of Oil Vacuum Pumps

When selecting an oil vacuum pump in 2025, understanding technical specifications is crucial. The pumping speed, measured in liters per second (L/s), dictates how quickly the pump can remove air and vapors. A higher pumping speed is beneficial for larger systems needing rapid evacuation. For instance, pumps with speeds of 20 L/s can efficiently serve mid-sized applications, while industrial setups may require 100 L/s or more.

Another important specification is ultimate vacuum, which indicates how low a pump can achieve pressure. Many models reach vacuum levels of 0.1 mbar or lower, essential for applications requiring a clean and dry environment. Reports from industry experts note that pumps achieving 0.01 mbar fail to deliver consistent performance in certain scenarios, raising questions about long-term reliability.

Material construction impacts durability and performance. Pumps made of stainless steel often perform better in corrosive environments. However, they come with higher costs. Users may struggle with this trade-off. Also, noise levels, typically measured in decibels (dB), should not be overlooked. Noise can affect operational environments. Units generating sound levels of 60 dB may be inadequate for noise-sensitive setups. Balance specifications carefully to meet both performance and environmental needs.

Assessing the Maintenance and Operational Costs of Different Models

When selecting an oil vacuum pump, understanding maintenance and operational costs is key. Choices can vary widely. Some pumps require regular oil changes and have intricate parts. Others may come with fewer maintenance needs but higher initial costs. Evaluate what fits your budget and requirements.

It's essential to consider energy consumption as well. A more efficient pump may reduce your energy bills but could be more expensive upfront. Think about the long-term implications of your choice. Review the expected lifespan of different models. Some pumps may need replacements sooner than anticipated, increasing overall expenses.

Consider user reviews or feedback. Not every pump lives up to expectations. Some users report unforeseen costs or frequent breakdowns. Reflect on what you truly need versus what looks appealing. Making an informed decision is vital, or you might find yourself regretting your choice down the line.

How to Choose the Right Oil Vacuum Pump for Your Needs in 2025

| Model | Capacity (CFM) | Power Consumption (kW) | Maintenance Cost (Annual) | Operational Cost (per hour) |

|---|---|---|---|---|

| Model A | 5 | 1.0 | $150 | $0.05 |

| Model B | 10 | 2.5 | $200 | $0.10 |

| Model C | 15 | 3.0 | $250 | $0.15 |

| Model D | 20 | 4.0 | $300 | $0.20 |

| Model E | 25 | 5.0 | $350 | $0.25 |

Exploring Future Trends in Oil Vacuum Pump Technology for 2025

As we approach 2025, oil vacuum pump technology is evolving rapidly. Innovations focus on energy efficiency and user-friendliness. The integration of smart technology enhances monitoring and control. Users can track performance in real-time. This feature may reduce downtime and improve maintenance.

Another trend is the shift towards environmentally friendly designs. Manufacturers are exploring sustainable materials. This shift could lead to a smaller carbon footprint. However, transitioning to greener technologies may come with challenges. Not all users may be ready to invest in new systems. The cost of adoption might deter some.

Additionally, we’re seeing a rise in compact and portable models. These are essential for industries with space constraints. Users might appreciate the flexibility of these designs. But, smaller models may compromise on power. Balancing size and performance requires careful consideration. Future buyers must evaluate their specific needs to make informed decisions.

Related Posts

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

How to Choose the Right High Vacuum Pump for Your Industrial Needs

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

-

The Essential Guide to Understanding Oil Vacuum Pumps and Their Applications in Industry