- Eng

- Deu

- Fra

How to Choose the Right Oil Pumps for Your Needs?

Choosing the right oil pumps can significantly affect various applications. The right pump ensures efficiency and reliability. With numerous options available, making a decision can feel overwhelming.

When selecting oil pumps, consider the specific needs of your project. Factors like viscosity, flow rate, and operating environment impact performance. For example, a pump intended for heavy oil will differ from one designed for light oil. Neglecting these details may lead to inefficiency.

It is important to acknowledge that not all pumps are created equal. Brands vary in quality and durability. Seeking feedback from other users can provide helpful insights. Reflecting on this process ensures you make a well-informed choice. The right oil pump can make all the difference in your operations.

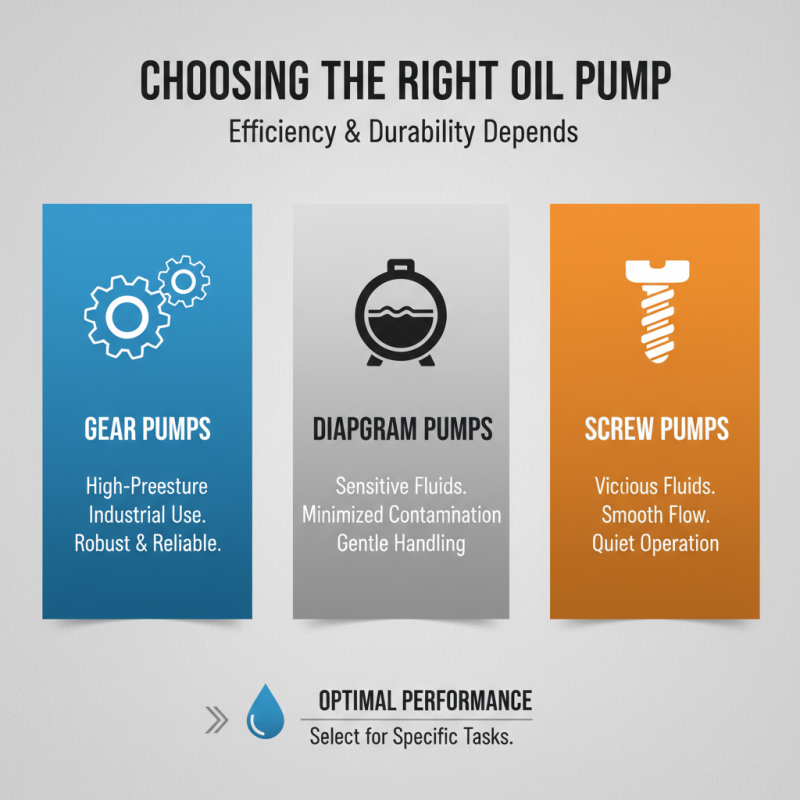

Understanding Different Types of Oil Pumps Available in the Market

Choosing the right oil pump is crucial. It impacts efficiency and durability. The market presents various types, each designed for specific tasks. Gear pumps, diaphragm pumps, and screw pumps are common options. Gear pumps excel in high-pressure applications. They are popular in industrial settings. Diaphragm pumps, however, are preferred for sensitive fluids. Their design minimizes contamination risks.

According to a recent market analysis, the global oil pump market is expected to grow by over 6% annually. Demand for efficient systems drives this growth. In automotive sectors, oil pumps contribute to engine performance. They ensure proper lubrication, extending engine life. Conversely, some users overlook the specifications. This can lead to dissatisfaction and failures.

Screw pumps are versatile, handling various fluids. They maintain a steady flow rate, suitable for many applications. Still, selecting the right material is essential. Some pumps may corrode quickly. Always consider the fluid’s attributes before making a choice. The industry needs constant reassessment of needs. Users might find themselves regretting decisions made in haste. Choosing the right pump requires focus and understanding.

Evaluating the Specific Requirements for Your Oil Pump Application

Choosing the right oil pump starts with understanding specific requirements. Each application has unique demands that determine the type of pump you'll need. For instance, viscosity characteristics of the oil play a crucial role. A report by the International Journal of Fluid Mechanics highlights that higher viscosity oils require pumps with greater torque.

Additionally, the flow rate is essential. A typical operation might need 5 to 50 gallons per minute. If the flow rate is too low, it can lead to inefficiencies. Conversely, if it’s too high, you may waste energy. In some systems, pumps operate at pressures over 150 psi. This creates concerns over overheating and maintenance costs.

Material selection is another critical factor. Many pumps interact with corrosive substances. A study from the Society of Automotive Engineers indicates that certain materials wear down faster under these conditions. Regular assessments can prevent unexpected failures. Without proper analysis, it's easy to overlook potential issues. Often, operators may ignore the long-term effects of poor material compatibility.

Key Factors to Consider When Selecting an Oil Pump

Selecting the right oil pump can greatly impact the efficiency of your equipment. When considering an oil pump, the application is crucial. Factors like temperature, viscosity, and flow rate play significant roles. For example, a high-viscosity oil may need a stronger pump. Don't assume one size fits all.

Durability is another key consideration. Look for materials that resist corrosion and wear. Pumps are often exposed to harsh conditions. Regular maintenance can prolong pump life, but be aware that some designs are inherently more reliable. Understand that not all pumps are easy to maintain and those that are complex can lead to frustration.

Cost is always a factor, but cheaper options may not perform well. A low-cost pump can lead to frequent replacements. Analyze your budget against long-term needs. Sometimes, investing in a higher-quality product pays off in the long run. Reflect on the consequences of your choices, as a good pump is essential for smooth operations.

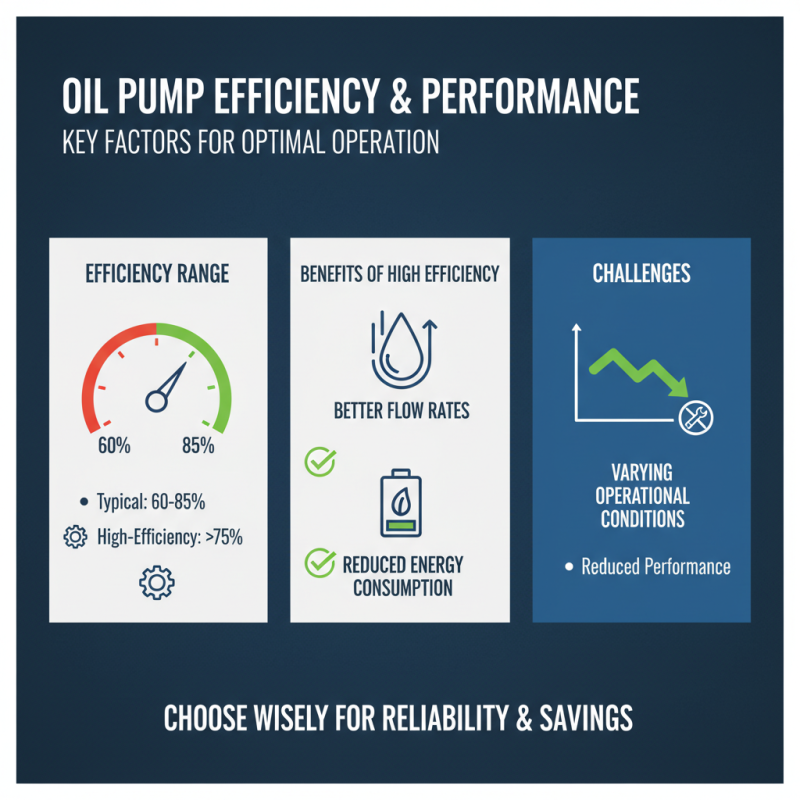

Comparing Efficiency and Performance Ratings of Oil Pumps

When choosing oil pumps, efficiency and performance ratings are critical factors. Industry reports indicate that the efficiency of oil pumps can range from 60% to 85%. High-efficiency models typically offer better flow rates and reduced energy consumption. However, achieving efficiency is not always straightforward. Some pumps may struggle under varying operational conditions, which can lead to reduced performance.

Performance ratings often depend on the specific application. For example, centrifugal pumps are efficient for low-viscosity fluids, but may falter with thicker oils. According to a recent study, 40% of users reported dissatisfaction due to inappropriate pump selection for high-viscosity liquids. These findings stress the importance of understanding the application's unique requirements before making a choice.

It's essential to consider the total cost of ownership, not just the initial purchase price. Maintenance costs can significantly impact the overall efficiency. A report from an industry association highlighted that poorly maintained pumps can lose nearly 15% of their efficiency over time. Selecting the right oil pump involves assessing not just the specs, but also your specific needs, potential obstacles, and maintenance capabilities.

Maintenance Tips for Ensuring Longevity of Your Chosen Oil Pump

Maintaining your oil pump properly is crucial for its longevity. Regular maintenance helps prevent unexpected failures. Check the oil levels frequently. Too little oil can cause overheating and damage. Clean the pump's filter regularly to ensure it runs smoothly. Clogged filters affect performance.

Consider the environment where the pump operates. Extreme temperatures can wear down components. If your pump is in a dusty area, dust can build up and impair functionality. Inspect seals and gaskets for signs of wear. Replace them as needed to avoid leaks.

Communication with experts can offer insights. However, not all advice fits every situation. Reflect on your specific needs and challenges. Document your maintenance routine. This will help you track issues over time. Remember, neglecting maintenance can lead to higher costs down the road.

Oil Pump Maintenance and Efficiency Comparison

This chart illustrates the efficiency and maintenance frequency of various types of oil pumps. The data represents the average performance ratings and recommended maintenance intervals for commonly used oil pumps.

Related Posts

-

How to Choose the Right Oil Pumps for Your Industrial Needs

-

Understanding the Future of Energy: How Oil Pumps Power the Transition to Renewable Resources

-

Why Oil Pumps Are Essential for Efficient Fluid Management in Industrial Applications

-

How to Effectively Pump Oil for Maximum Efficiency and Safety

-

Understanding the Efficiency and Applications of Rotary Vane Vacuum Pumps in Modern Industries

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications