- Eng

- Deu

- Fra

How to Choose the Right Oil Pumps for Your Industrial Needs

In the industrial landscape, selecting the right oil pumps is crucial for operational efficiency and reliability. According to a recent report by Grand View Research, the global oil pump market is expected to reach USD 11.26 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.6%. This growth highlights the increasing demand for efficient pumping solutions across various sectors, such as oil and gas, automotive, and manufacturing. As industries adopt more advanced technologies, the importance of choosing the right oil pumps becomes even more pronounced.

Expert insights further illuminate this topic. John Smith, a renowned engineer in the oil and gas industry, emphasizes, “The efficiency and longevity of industrial operations largely depend on the quality and suitability of the oil pumps in use.” Understanding the specific requirements of your application—be it viscosity, temperature, or flow rate—is fundamental to identifying the optimal pump solution. This journey towards selecting the right oil pumps is not only about performance but also involves considerations of energy efficiency and maintenance costs, making informed decisions paramount for industrial success.

Understanding the Different Types of Oil Pumps Available in Industry

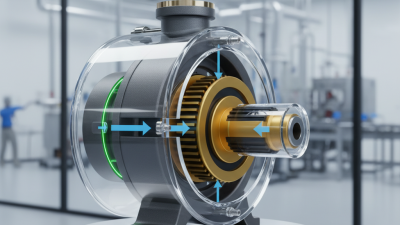

When selecting an oil pump for industrial applications, it is essential to understand the different types available and their respective functions. Centrifugal pumps are among the most common types used across various industries. They operate based on rotational energy, using a rotating impeller to move oil. These pumps are ideal for high flow rates and are often used in situations where the viscosity of the oil is low, making them suitable for water-like fluids.

Another popular type is the positive displacement pump, which moves oil by trapping a fixed amount of fluid and forcing it into the discharge pipe. They are particularly effective for high-viscosity oils, where centrifugal pumps may struggle. Within this category, you can find rotary, diaphragm, and gear pumps, each providing unique features tailored to specific applications. Understanding the requirements of your project, such as the viscosity of the oil, the flow rate needed, and the pressure conditions, is crucial in determining which type of oil pump will best meet your operational needs.

How to Choose the Right Oil Pumps for Your Industrial Needs

| Pump Type | Application | Flow Rate (liters/minute) | Pressure Rating (bar) | Efficiency (%) |

|---|---|---|---|---|

| Gear Pump | Hydraulic Systems | 50 | 100 | 85 |

| Diaphragm Pump | Chemical Transfer | 30 | 50 | 75 |

| Centrifugal Pump | Water Supply | 100 | 40 | 90 |

| Lobe Pump | Food Processing | 60 | 60 | 80 |

| Peristaltic Pump | Laboratory Applications | 20 | 30 | 70 |

Key Factors to Consider When Selecting an Oil Pump

When selecting an oil pump for industrial applications, several key factors must be considered to ensure optimal performance and efficiency. First, understanding the viscosity of the oil being pumped is crucial. Different oils vary in thickness, which directly influences the type of pump needed. Pumps must be selected based on their ability to handle specific viscosity ranges to prevent issues such as cavitation or inadequate flow rates.

Another important consideration is the pump's capacity and flow rate. This involves evaluating the required volume of oil to be moved within a specific timeframe. Accurately calculating the flow rate needed for your operation ensures that the chosen pump can meet production demands without causing delays or inefficiencies. Additionally, the operational environment should not be overlooked. Factors such as temperature, pressure, and the presence of contaminants in the working area can significantly affect pump performance and longevity. Selecting a pump that is resilient to environmental conditions and compatible with the oil being used will enhance both reliability and effectiveness in the long run.

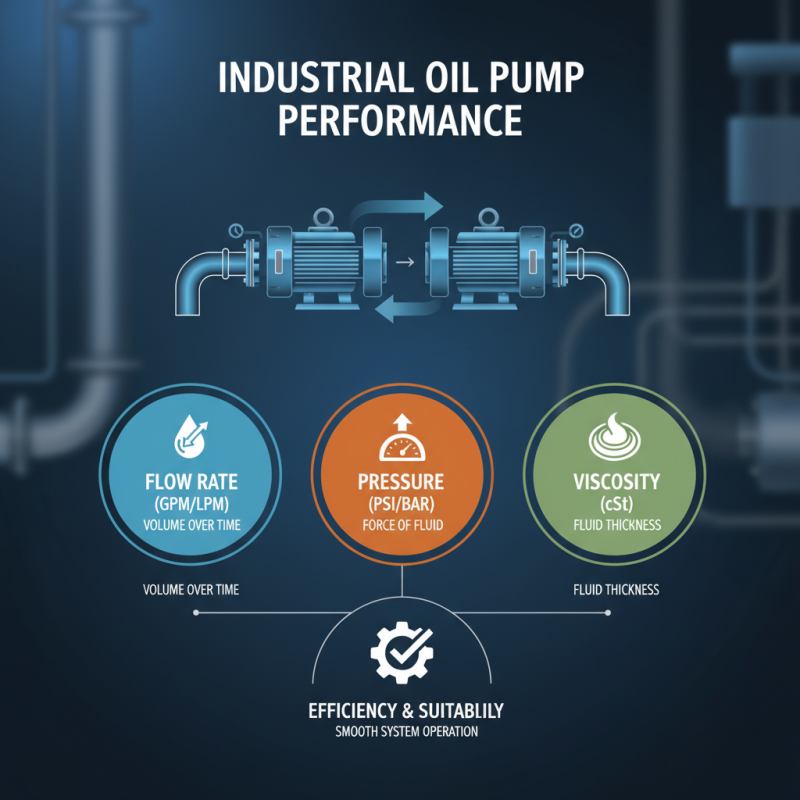

Evaluating Pump Performance: Flow Rate, Pressure, and Viscosity

When selecting oil pumps for industrial applications, evaluating pump performance is crucial. Key performance metrics to consider include flow rate, pressure, and viscosity, which collectively influence the pump's efficiency and suitability for specific tasks. The flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), indicates the volume of fluid that the pump can move within a given time frame. A suitable flow rate ensures that your system operates smoothly without bottlenecks, especially in high-demand applications.

Pressure is another essential factor, as it determines the pump's ability to overcome resistance within the system, ensuring fluid is delivered at the required force. Understanding the pressure needs of your operation helps in selecting a pump that can effectively maintain the desired output. Additionally, viscosity, the measure of a fluid’s thickness, greatly affects pump performance; thicker fluids may require specialized pump designs that can handle higher resistance without compromising efficiency.

Tips: Always consult with industry experts or reference performance charts when selecting pumps to get an accurate assessment of whether a pump meets your application needs. Consider conducting a flow study in your operational environment to gather real-time data on how different viscosities impact system performance. It’s essential to factor in not just the current requirements but also future changes in production demands to select a pump that remains effective over time.

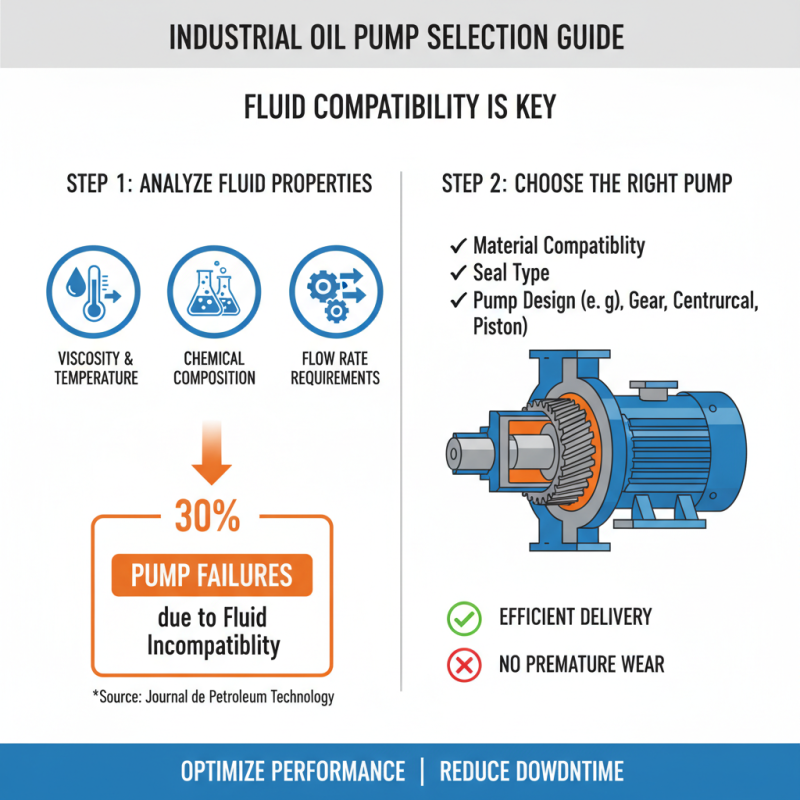

Assessing Compatibility with Your Industrial System and Fluids

When selecting the right oil pumps for industrial applications, compatibility with your existing systems and the fluids being handled is paramount. The first step is to analyze the specific properties of the fluids in use, such as viscosity, temperature, and chemical composition. According to a report by the Journal of Petroleum Technology, over 30% of industrial pump failures can be attributed to incompatibility with the pumped fluids. Therefore, understanding the fluid characteristics helps in selecting a pump that can efficiently deliver the required flow rates without degradation or premature wear.

Tips: Conduct thorough fluid tests to determine properties like viscosity index and corrosiveness. This can save time and costs in the long run by preventing equipment failures.

Moreover, it's essential to consider the existing industrial system's specifications, including pressure ratings and delivery methods. For instance, a compatibility assessment should also include the pump's material construction, as improper materials can lead to leaks or failures under pressure. The Hydraulic Institute emphasizes that pumps operating under untested conditions can face up to 40% increased operational costs due to inefficiencies. Thus, ensuring that the selected pump aligns with both the fluid and system requirements is crucial.

Tips: Ensure that the pump's material is suitable for both the fluid and the expected operational conditions to prolong the lifespan of your equipment.

Maintenance and Durability Considerations for Oil Pumps

When selecting oil pumps for industrial applications, maintenance and durability are critical aspects that should not be overlooked. An oil pump must be able to withstand harsh operating conditions while ensuring a consistent performance. Regular maintenance checks are essential to identify potential issues like wear and tear. Implementing a scheduled maintenance routine will help prolong the lifespan of the pumps and prevent unexpected breakdowns.

**Tips:** Always refer to the manufacturer’s guidelines for recommended maintenance intervals and procedures. Regularly inspect components for signs of wear, including seals and bearings, as these are often the first to experience degradation.

Durability considerations also extend to the environment in which the oil pumps operate. Factors such as temperature fluctuations, humidity, and exposure to corrosive substances can significantly impact the pump's performance. Selecting pumps made from durable materials designed to resist these environmental challenges can greatly enhance their service life.

**Tips:** Consider investing in protective coatings or enclosures that can shield the pump from harsh conditions. Conducting a thorough risk assessment of the operating environment will aid in making informed decisions about the right pump materials and designs for your specific needs.

Oil Pump Maintenance and Durability Analysis

Related Posts

-

Understanding the Future of Energy: How Oil Pumps Power the Transition to Renewable Resources

-

Why Oil Pumps Are Essential for Efficient Fluid Management in Industrial Applications

-

How to Effectively Pump Oil for Maximum Efficiency and Safety

-

Understanding Waste Pumps How They Work and Their Importance in Modern Waste Management

-

Top 10 Benefits of Using Rotary Vane Vacuum Pumps for Your Applications

-

The Essential Guide to Understanding Oil Vacuum Pumps and Their Applications in Industry