- Eng

- Deu

- Fra

How to Choose the Right High Vacuum Pump for Your Industrial Needs

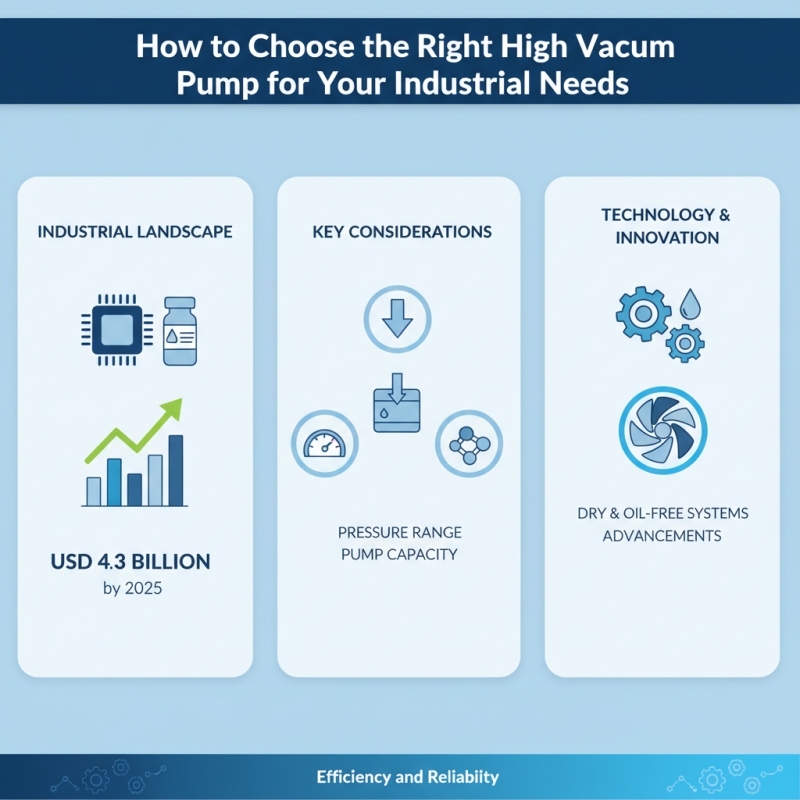

In today's industrial landscape, the importance of choosing the right high vacuum pump cannot be overstated. With applications spanning across semiconductor manufacturing, pharmaceuticals, and research laboratories, the demand for high-performance vacuum solutions is projected to grow significantly. According to a report by MarketsandMarkets, the global vacuum pump market is expected to reach USD 4.3 billion by 2025, with a substantial portion attributed to the rising need for high vacuum systems. The efficiency and reliability of high vacuum pumps play a critical role in ensuring optimal production processes and high-quality outputs, making it essential for industries to understand their specific requirements.

Selecting the appropriate high vacuum pump involves considering factors such as the required pressure range, pump capacity, and the nature of the gases being evacuated. A comprehensive understanding of these specifications can enable industries to enhance operational efficiency and reduce downtime. Furthermore, advancements in pump technology, including the development of dry and oil-free systems, have broadened the options available to manufacturers in various sectors. As such, it is crucial for industrial stakeholders to be informed about the latest innovations and industry standards to ensure they invest in the most suitable high vacuum pump for their unique applications.

Understanding High Vacuum Pump Types and Their Applications

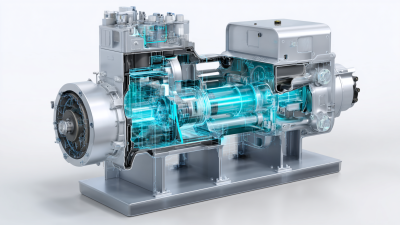

When selecting a high vacuum pump for industrial applications, it is crucial to understand the various types available and their specific applications. High vacuum pumps can be categorized into two primary types: positive displacement pumps and momentum transfer pumps. Positive displacement pumps, such as rotary vane and diaphragm pumps, operate by capturing and compressing gas for evacuation. They are often favored in applications requiring lower vacuum levels and can achieve vacuum levels of around 10-3 to 10-5 torr. In contrast, momentum transfer pumps, like turbomolecular and diffusion pumps, excel at reaching ultra-high vacuum levels, often achieving pressures as low as 10-9 torr. These pumps are ideal for semiconductor manufacturing and scientific research that demands extremely clean environments.

According to a report by Allied Market Research, the global high vacuum pump market was valued at approximately $2.1 billion in 2021 and is expected to reach $3.5 billion by 2031, growing at a compound annual growth rate (CAGR) of around 5.3%. This growth is largely driven by advancements in technologies within the semiconductor, aerospace, and medical industries, where high-performance vacuum systems are essential. Understanding the specific requirements of your application—such as the required vacuum level and process compatibility—will guide you in selecting the most suitable pump type, ensuring optimal performance and efficiency in your industrial processes.

Evaluating Pump Specifications: Flow Rate, Pressure, and Compatibility

When selecting a high vacuum pump for industrial applications, it’s crucial to evaluate specific pump specifications such as flow rate, pressure, and compatibility with the materials and processes involved. The flow rate refers to the volume of gas the pump can move in a given time frame, which directly influences the efficiency and speed of your operations. A pump with a higher flow rate can evacuate the system quickly, making it particularly suitable for processes requiring rapid vacuum creation.

Pressure specifications also play a significant role in pump selection. Different applications may require varying levels of vacuum, so it's essential to choose a pump that can achieve the desired low-pressure levels reliably. Consider the ultimate pressure the pump can achieve and ensure it aligns with your operational requirements. Additionally, understanding the pump's operating range, such as backing pressure and dynamic performance under load, is vital for maintaining optimal efficiency.

Tips: Before making a purchase, evaluate the compatibility of the pump with the gases and vapors it will handle. Ensure that the pump materials are resistant to corrosion and suitable for the chemical nature of the substances processed. It's also advisable to consider maintenance requirements, as some pumps may demand more frequent servicing or parts replacement, affecting long-term operational efficiency and costs.

Assessing Material and Design for Chemical Resistance and Durability

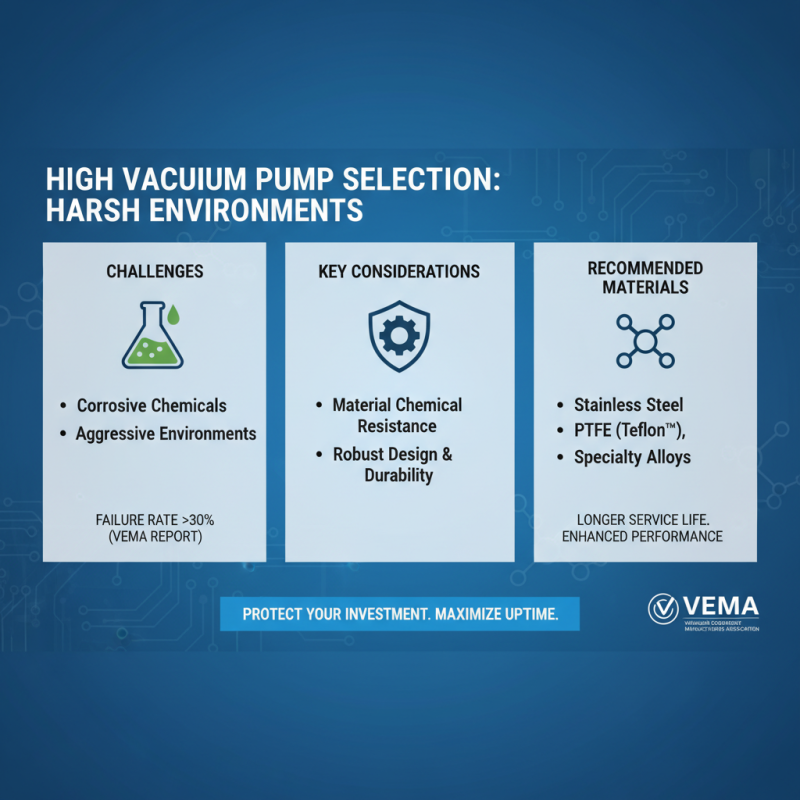

When selecting a high vacuum pump, especially for industrial applications involving corrosive chemicals or harsh environments, assessing material and design for chemical resistance and durability is of paramount importance. According to a report by the Vacuum Equipment Manufacturers Association (VEMA), improper material selection can lead to pump failure rates exceeding 30% within the first year of operation, highlighting the significance of using suitable materials that can withstand aggressive chemicals. Materials such as stainless steel, PTFE, and certain alloys have shown superior resistance to a wide array of corrosive substances, ensuring a longer service life and enhanced performance efficiency.

In addition to material selection, the design of the vacuum pump plays a crucial role in its durability. Pumps designed with features that minimize wear and tear, such as advanced sealing mechanisms and low-friction components, can provide significant advantages. The American Vacuum Society (AVS) indicates that high-quality designs that incorporate robust engineering can reduce maintenance frequency by up to 50% and improve overall reliability. Therefore, manufacturers that invest in advanced materials and thoughtful designs not only enhance chemical resistance but also minimize long-term costs associated with downtime and repairs. Taking into account these factors is essential for ensuring that high vacuum pumps can meet industrial demands effectively and sustainably.

Analyzing Energy Efficiency and Operating Costs of High Vacuum Pumps

When selecting the right high vacuum pump, one of the critical considerations is its energy efficiency and operating costs. According to a report by the International Energy Agency (IEA), vacuum pumps account for approximately 5-10% of energy consumption in industrial applications. Therefore, choosing a pump with a high energy efficiency rating can lead to significant savings on operational costs over time. For instance, pumps that utilize advanced motor technologies and variable frequency drives can reduce energy consumption by as much as 30%, making them an attractive option for industries looking to minimize their carbon footprint and operating expenses.

Moreover, understanding the total cost of ownership (TCO) is essential in making an informed decision. A comprehensive study published by the Vacuum Technology Group indicates that besides the initial purchase price, operational costs—including maintenance, electricity, and downtime—can substantially affect the overall investment. For example, a well-maintained high vacuum system can have a service life extending beyond ten years, whereas neglecting maintenance could lead to a significant drop in efficiency and an increase in failure rates, ultimately resulting in higher costs. Evaluating these factors helps ensure that the chosen pump not only fits the technical requirements but also aligns with the long-term financial goals of the operation.

Energy Efficiency and Operating Costs of High Vacuum Pumps

Determining Maintenance Requirements for Optimal Pump Performance

When selecting a high vacuum pump for industrial applications, understanding and determining maintenance requirements is critical to ensure optimal pump performance. Regular maintenance not only enhances reliability but also prolongs the life of the pump. According to the 2022 Vacuum Technology Report, routine maintenance practices including regular inspections and prompt servicing can reduce downtime by up to 30%. This ensures that any wear and tear is identified early, particularly in components such as seals and bearings, which are vital for maintaining vacuum integrity.

The maintenance frequency is often dictated by the operational environment and the specific application. For instance, a high vacuum pump operating in a dusty or corrosive environment may require more frequent servicing compared to one in a controlled environment. The Vacuum Industry Association suggests implementing a predictive maintenance strategy that uses data analytics to monitor pump performance continuously. Such strategies can lead to early detection of potential issues, minimizing interruptive repairs and allowing for maintenance to be scheduled during non-peak hours. Utilizing performance metrics can also help in understanding the necessary intervals for fluid changes, which is crucial for maintaining efficient operation and preventing overheating and other complications.

How to Choose the Right High Vacuum Pump for Your Industrial Needs - Determining Maintenance Requirements for Optimal Pump Performance

| Pump Type | Ideal Applications | Maintenance Frequency | Common Issues | Performance Tips |

|---|---|---|---|---|

| Rotary Vane Pump | Laboratories, Food Packaging | Monthly | Oil leaks, Vane wear | Regular oil checks and replacements |

| Diffusion Pump | Semiconductor Manufacturing | Quarterly | Overheating, Contamination | Ensure proper cooling is maintained |

| Scroll Pump | Vacuum Packaging, Pharmaceutical | Biannual | Loss of suction, Noise increase | Maintain clean environment, regular checks |

| Piston Pump | Aerospace, Automotive | Annually | Piston wear, Seal failures | Regularly inspect seals and pistons |

Related Posts

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

The Essential Guide to Understanding Oil Vacuum Pumps and Their Applications in Industry

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

Maximizing Efficiency: The Impact of Industrial Vacuum Blowers on Energy Consumption in Manufacturing