- Eng

- Deu

- Fra

How to Choose the Best Heavy Duty Vacuum Pump for Your Needs?

Choosing the right heavy duty vacuum pump can be challenging. There are many options on the market. Each option has its own strengths and weaknesses.

When selecting a heavy duty vacuum pump, consider your specific needs. Think about the tasks you will perform. Some pumps excel in certain conditions, while others may not. You might need a pump for industrial use or for home projects.

Look closely at features such as capacity and durability. These details are crucial for effective operation. Not all heavy duty vacuum pumps will suit your needs perfectly. It’s important to reflect on what you truly require. Doing this will lead you to a more informed choice.

Understanding the Different Types of Heavy Duty Vacuum Pumps

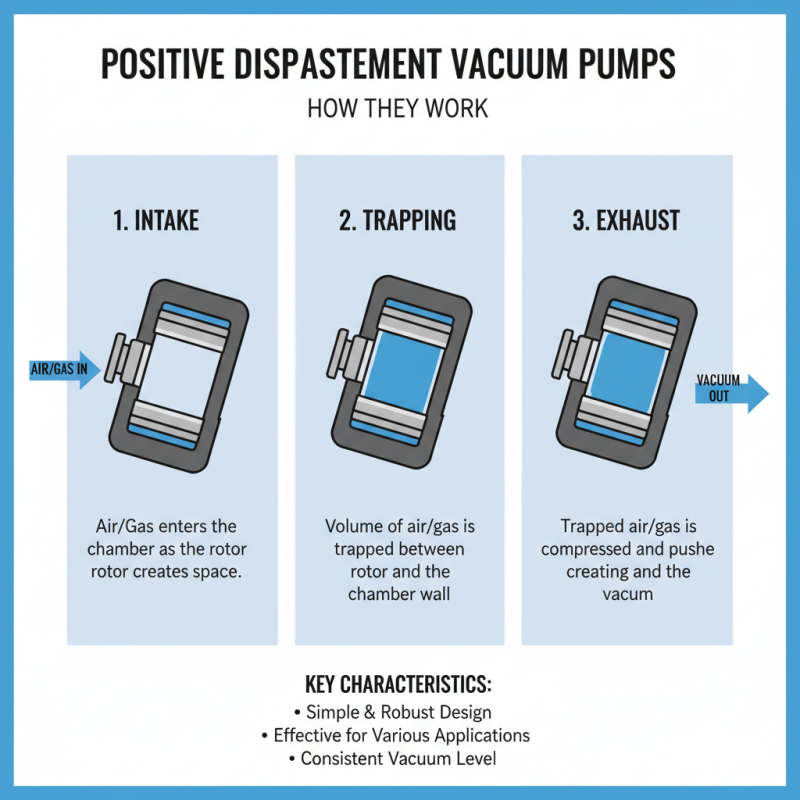

When choosing a heavy duty vacuum pump, understanding the types available is crucial. There are positive displacement pumps, which trap air in a chamber. As it fills, the air is pushed out, creating a vacuum. These are straightforward and effective for many tasks.

Another option is the ejector pump. It uses a high-pressure fluid to move air out of a chamber. This type is flexible and can handle different applications. You might also encounter rotary vane pumps. They operate using a rotating mechanism, making them efficient for continuous use. Yet, maintenance is key; without it, performance can drop.

Consider your specific needs. Are you dealing with larger volumes of air? A positive displacement pump might be the best fit. But if you need versatility, an ejector pump could be beneficial. Each type has its strengths and weaknesses. It’s essential to weigh these aspects to find the right one. Don’t overlook the importance of proper maintenance, either. Neglecting this can lead to operational issues down the line.

Key Features to Consider When Selecting a Vacuum Pump

When selecting a heavy-duty vacuum pump, several key features need consideration. The pump's capacity is crucial. Determine the required flow rate, typically measured in cubic feet per minute (CFM). Industry reports show that most heavy-duty pumps range from 2 to 20 CFM. A higher flow rate means faster work completion. Yet, oversizing can lead to inefficiencies.

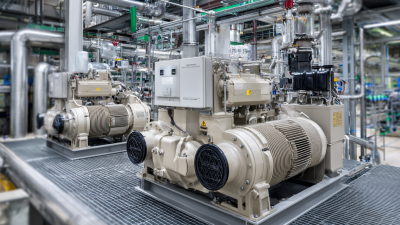

Next, consider the pump's application. Are you using it for industrial, automotive, or laboratory tasks? Each application has specific needs. The material construction matters too. Look for durable options like stainless steel or heavy-duty aluminum. These materials resist wear over time and ensure longevity.

Noise levels should not be overlooked. Heavy-duty pumps can be loud, often exceeding 80 dB. That can impact the work environment. Decide if you need a quieter model. Lastly, examine maintenance requirements. Some models require frequent oil changes or filter replacements. Frequent upkeep can disrupt workflows. The right choice balances power, durability, and practical maintenance needs.

Comparison of Key Features in Heavy Duty Vacuum Pumps

Assessing Your Specific Needs and Applications

When choosing a heavy-duty vacuum pump, clarity about your needs is crucial. Consider what you plan to use it for. Are you handling liquids, gases, or both? Each application demands different specifications. For example, pumps for transferring corrosive liquids require specific materials, which can impact durability and performance. Think about the environment too. Will the pump operate in harsh conditions? Addressing these factors is vital.

Next, evaluate the required pressure levels. Different tasks will have different vacuum strength needs. It’s common to underestimate this aspect. A pump may struggle if it lacks sufficient power. Noise level is another often-overlooked detail. A quieter model might be beneficial for certain settings. Size and weight also play roles in practicality. If space is limited, a compact design could be essential. Reflect on these details to avoid frustration later.

Evaluating Vacuum Pump Performance Metrics

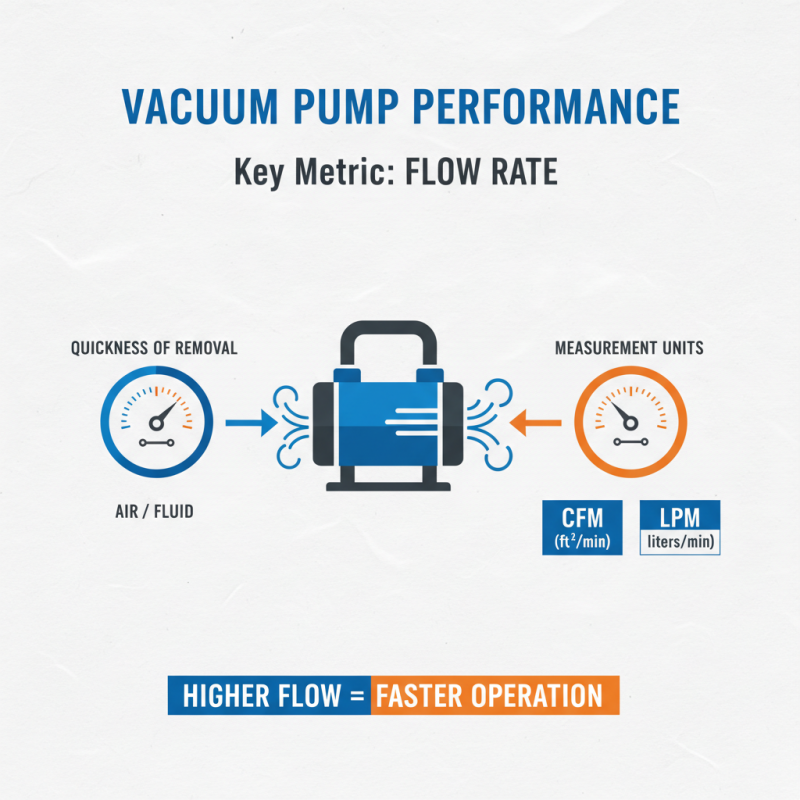

When evaluating vacuum pump performance metrics, focus on the key specifications. The flow rate is crucial. It indicates how quickly the pump can remove air or fluid. Measure it in cubic feet per minute (CFM) or liters per minute (LPM). Higher flow rates reduce the time needed for operation.

Pressure level matters too. Look for models with a low ultimate vacuum. This number shows the pump's ability to reach deep vacuum levels. A lower measurement means better performance. Also, consider the noise level. Too much sound can be distracting in a workspace.

**Tip:** Always check the warranty. A longer warranty often reflects better quality.

Another aspect to think about is energy consumption. Some pumps can be inefficient, leading to high electricity bills. Ensure the model is energy-efficient. This saves money long-term.

**Tip:** Read user reviews for real-world insights. Users often highlight issues and benefits you might miss.

Comparing Brands and Models for Quality and Reliability

When it comes to selecting a heavy-duty vacuum pump, brand reputation plays a significant role. According to the Vacuum Technology Association, reliability is paramount; 78% of professionals prefer brands recognized for quality. A strong brand often indicates higher durability and performance over time. However, it's crucial not to overlook lesser-known brands that may offer comparable quality at a lower cost. Sometimes, a smaller manufacturer can provide specialized options tailored to unique needs.

Exploring models requires careful consideration of specifications. Pumps with higher CFM (Cubic Feet per Minute) ratings are essential for large-scale applications. Research shows that a 20% increase in CFM can lead to 15% better efficiency. Noise levels are another factor. Many users find that models above 70 dB are undesirable, especially in noise-sensitive environments. Yet, high-performing pumps can sacrifice noise for power, creating a trade-off scenario.

Even with detailed comparisons, imperfections exist in every model. Customer reviews often highlight issues like maintenance difficulties or part replacements that could affect long-term performance. Investing time in researching user feedback may unveil these hidden concerns. Selecting the right vacuum pump is a balance of understanding features, evaluating real user experiences, and knowing what you can compromise on.

Related Posts

-

What is a Vacuum Blower Pump and How Does It Work in Industry

-

Maximizing Efficiency: The Impact of Industrial Vacuum Blowers on Energy Consumption in Manufacturing

-

What is an Oil Vacuum Pump and How Does it Work for Efficient Operations

-

How to Choose the Right High Vacuum Pump for Your Industrial Needs

-

2026 How to Choose the Right Rotary Vane Vacuum Pump for Your Needs?

-

Why Are Septic Pumps Essential for Your Home System?