- Eng

- Deu

- Fra

2026 How to Choose the Right Liquid Vacuum Pump for Your Needs?

Choosing the right liquid vacuum pump is crucial for various applications. The market offers many options, each with unique features. Understanding your needs will help narrow down your choices.

Liquid vacuum pumps are vital for processes like distillation and filtration. They create suction by removing air and vapor. Different models have varying capacities and materials, impacting performance and durability. It's essential to consider your specific requirements.

Pay attention to details like pump size and maintenance needs. Some users overlook these factors, leading to issues down the line. Rushing this decision can result in inefficiency or increased costs. Reflect on your operational needs before making a choice.

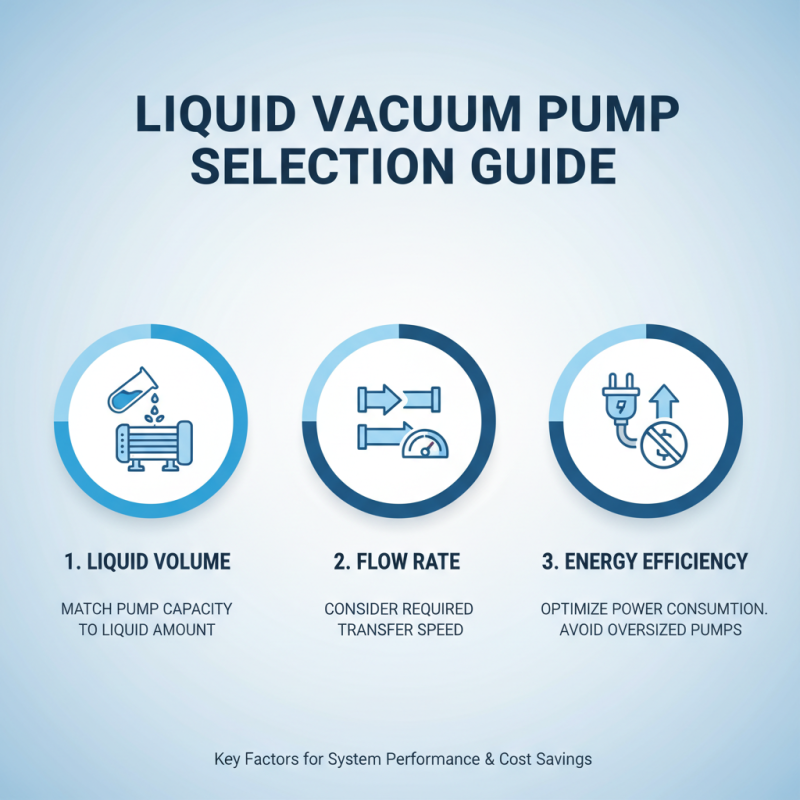

Factors to Consider When Selecting a Liquid Vacuum Pump

When selecting a liquid vacuum pump, several key factors come into play. Understanding your specific needs is crucial. Consider the volume of liquid you will be handling. Different pumps have varying capacities. A pump that is too small may struggle. Conversely, an oversized pump can waste energy.

The type of liquid also matters. Some pumps are better suited for certain liquids than others. Corrosive liquids might require specialized materials. Think about the temperature range as well. Some pumps cannot handle extreme temperatures, leading to issues down the line. A careful evaluation of these aspects will help you make an informed decision.

Lastly, maintenance is an important consideration. Some pumps demand extensive upkeep, while others are more forgiving. This factor can impact long-term performance. Reflect on your willingness to perform regular maintenance. A reliable pump can significantly reduce downtime, but only if it fits your operational style. Make a checklist before finalizing your choice. It will guide you through the selection process smoothly.

Types of Liquid Vacuum Pumps and Their Applications

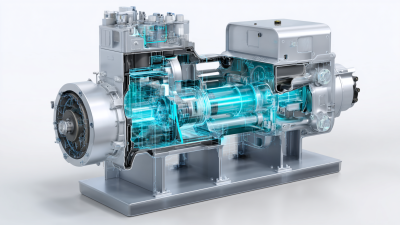

When selecting a liquid vacuum pump, understanding the types available is crucial. There are several types: diaphragm pumps, rotary vane pumps, and liquid ring pumps. Each type has unique features that cater to different applications. For instance, diaphragm pumps are ideal for handling corrosive liquids. They operate quietly and efficiently, making them suitable for laboratories.

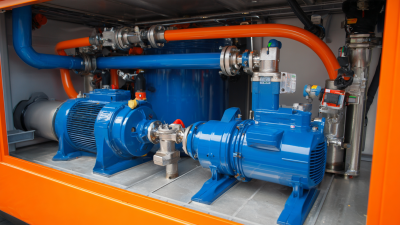

Rotary vane pumps find their use in industrial settings. They efficiently manage moderate vacuum levels. However, they may not be the best choice for all liquids. Consider the material compatibility to avoid any unforeseen issues. Liquid ring pumps excel in handling wet and vapor-heavy applications. They can operate silently and continuously, backing up their reliability in demanding environments.

**Tips**: Always assess the specific liquid you will be working with. Matching the pump material to the liquid type is vital. Regular maintenance keeps the pump running smoothly. Don't overlook the size and footprint of the pump; it should fit well within your workspace. Make sure to review the manufacturer’s specifications closely. This will guide you in choosing the most effective pump for your needs.

Understanding Pump Specifications and Performance Metrics

When selecting a liquid vacuum pump, understanding specifications is crucial. Start with the pump's capacity. This indicates how much liquid it can handle efficiently. A pump that is too small won’t meet your needs. A pump that is too large may waste energy and increase costs.

Next, focus on performance metrics. These details reveal the pump's efficiency under different conditions. Look at factors like maximum vacuum pressure and flow rate. These metrics determine how quickly the pump can remove liquid. Sometimes, advertised numbers can mislead. Always seek real-world test data where possible.

Consider the materials used in the pump's construction. Different liquids require specific materials. Inadequate compatibility can lead to corrosion and damage. Regular maintenance is vital. Even a durable pump may falter without proper care. Pay attention to user reviews for insights. They can help uncover hidden issues. Balancing your specific requirements with pump capabilities can be challenging.

Maintenance and Care for Liquid Vacuum Pumps

Maintaining a liquid vacuum pump is crucial for its efficiency and longevity. Regular checks are essential. Ensure the pump's exterior is clean and free of debris. Dust and grime can lead to overheating. A simple wipe can make a big difference.

Fluids inside the pump need attention too. Change them at recommended intervals. Old fluid can cause clogs or even damage components. Conduct visual inspections regularly. Look out for leaks or discoloration. These signs often mean it’s time for a maintenance review.

Noise can indicate issues. If the pump sounds different, investigate it promptly. Listen for unusual vibrations or rattling. They might suggest something is wrong. What's more, always refer to the manual. There might be specific care tips there. Ignoring maintenance can lead to costly repairs later on. Making a checklist can help keep track of necessary tasks. Reflect on your maintenance habits regularly; improvement is always possible.

Budgeting for Your Liquid Vacuum Pump Purchase and Operation Costs

When budgeting for a liquid vacuum pump, start by considering the initial purchase price. Quality designs may cost more upfront but can save on repairs later. Understand the specifications that match your tasks. A pump that’s too weak might lead to inefficiency. A powerful model could be unnecessary, driving costs higher.

Include operational costs in your budget. This includes energy consumption, maintenance, and potential upgrades. Some pumps consume more power than others. This can significantly impact your utility bills. Also, consider maintenance frequency. Pumps that require frequent servicing can rack up costs quickly.

Think beyond just the price tag. How often will the pump be used? If it’s only for occasional tasks, maybe a less expensive model suffices. Reflect on your needs and future plans. What is the expected growth of your operations? Be careful not to underestimate these factors, as they may lead to overspending. Always revisit your initial budget assumptions as the project develops.

Related Posts

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

2026 How to Choose the Right Rotary Vane Vacuum Pump for Your Needs?

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

How to Choose the Right Oil Vacuum Pump for Your Needs in 2025

-

Top 10 Vacuum Blower Pumps for Efficient Performance in Various Applications?

-

Top 5 Best High Vacuum Pumps for Efficient Performance?