- Eng

- Deu

- Fra

How to Choose the Right Vacuum Blower Pump for Your Needs?

Choosing the right vacuum blower pump is crucial for various industries. These pumps are essential in applications ranging from food processing to packaging. According to a report by MarketsandMarkets, the vacuum pump market is projected to reach $4.9 billion by 2025, reflecting the increasing demand for efficient equipment.

Expert Mark Thompson, a well-known figure in the vacuum design industry, once stated, "Selecting the appropriate vacuum blower pump can significantly enhance operational efficiency." This highlights the importance of making the right choice. Users often struggle with specifications and configurations. A mismatch can lead to performance issues or energy inefficiency.

Different industries have unique requirements. For example, a laboratory may need precise suction, whereas a factory demands high volume. Understanding your specific needs is vital. A pump that works well in one scenario might underperform in another. Therefore, careful consideration is necessary when evaluating options.

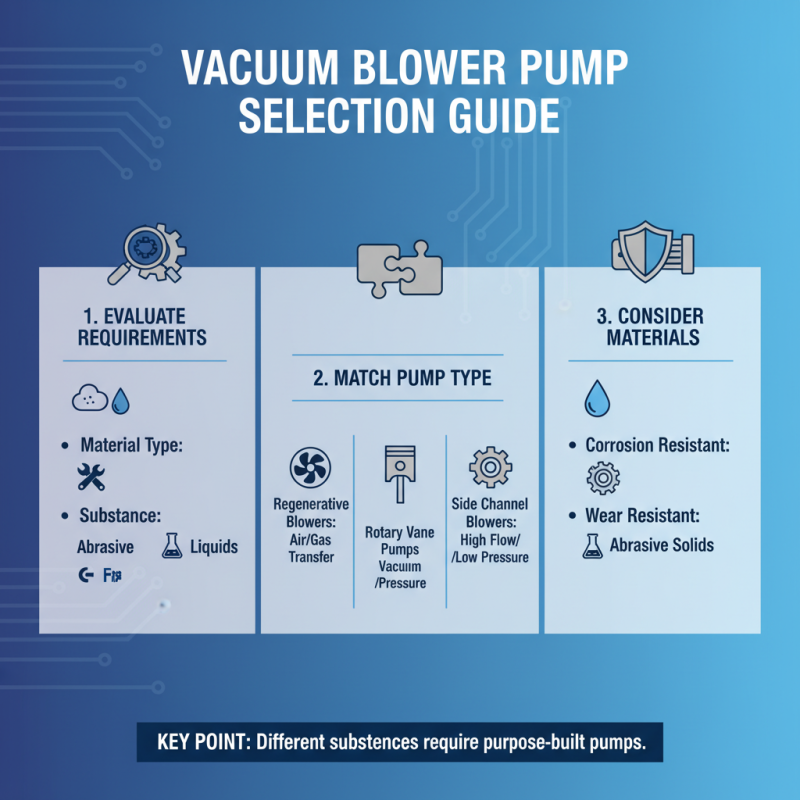

Understanding the Different Types of Vacuum Blower Pumps Available

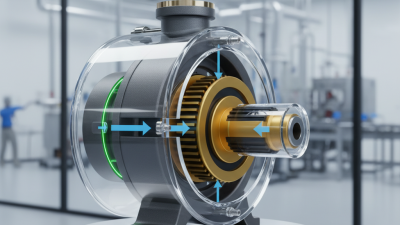

When selecting a vacuum blower pump, understanding the different types available is crucial. There are positive displacement pumps and regenerative blowers. Each type functions differently and serves specific needs. Positive displacement pumps are known for their ability to create high vacuum levels. They are typically used in industrial applications where precision is key.

On the other hand, regenerative blowers are designed for low vacuum applications. They work by circulating air continuously and are often quieter. This makes them suitable for environments where noise levels are a concern. However, they may not achieve the same vacuum levels as positive displacement pumps. Not every application requires the utmost power. It’s essential to match the equipment to your specific tasks.

Consideration of power source is vital too. Some pumps are electric, while others may run on compressed air. This decision impacts energy costs and efficiency. Reflecting on your goals can help determine the best choice. Balancing performance with your unique requirements may take time. It’s worth experimenting with different types to find the right fit for your needs.

Evaluating Your Specific Application Requirements for Pump Selection

When selecting a vacuum blower pump, start by evaluating your specific application requirements. Think about the materials you will handle. Consider whether you need to extract dust, fumes, or liquids. Each substance has different behavior and requires a pump designed for that purpose. For example, certain pumps can handle abrasive materials better than others.

Next, assess the capacity and flow rate you need. How much air or liquid do you need to move? The pump’s efficiency can vary significantly. A small pump might not keep up with larger operations, causing delays. Conversely, a pump that is too powerful could waste energy and may not fit the space available.

Don’t overlook noise levels. Some applications require quieter operations, especially in closed environments. Finally, consider if regular maintenance is manageable. Complex pumps might require expert care, while simpler models could suit less experienced users. Balancing these factors can lead to a more effective and efficient pumping solution tailored to your needs.

Key Features and Specifications to Consider in a Vacuum Blower Pump

When choosing a vacuum blower pump, several key features and specifications should be carefully considered. The pump's airflow capacity is crucial. It determines how efficiently it can move air. Make sure to check the CFM rating, as it indicates the volume of air processed. A higher CFM is generally better for larger jobs.

Another important specification is the vacuum pressure. Look for units with good pressure ratings to ensure effective vacuuming. Understand the application as well. Different tasks require different pressure levels. Some jobs may not need high vacuum levels, which can lead to wasted energy.

Material and build quality also matter. Durable construction ensures longevity, but it also affects performance. A lightweight pump may be easier to handle, yet it might be less durable. Noise levels can be a concern as well. A quieter unit can make working conditions more pleasant. It’s a balance. Reflect on your specific needs before making a choice.

Vacuum Blower Pump Performance Comparison

Assessing the Performance and Efficiency of Vacuum Blower Pumps

Choosing the right vacuum blower pump hinges on understanding its performance and efficiency. These metrics are vital for various applications, from industrial processes to home needs. A vacuum pump's efficiency can often be measured by its CFM (cubic feet per minute) rate, which indicates the volume of air a pump can evacuate. A report from the Vacuum Technology Association states that efficient pumps can achieve over 90% CFM under optimal conditions.

Tips: Ensure you assess the pump’s CFM at different altitudes and temperatures. Performance can vary significantly based on environmental factors.

The pump's energy consumption is also critical. According to a study by the Energy Efficiency Office, selecting an energy-efficient model can reduce operating costs by 30%. However, not all pumps perform well under various conditions. Some may lose efficiency when faced with unexpected loads or maintenance issues. It’s prudent to analyze specifications thoroughly and consider user reviews or case studies as part of your assessment.

Tips: Check for maintenance recommendations. A reliable pump should have clear guidance on upkeep. Neglect can lead to performance drops.

How to Choose the Right Vacuum Blower Pump for Your Needs?

| Pump Type | Max Vacuum (inHg) | Flow Rate (CFM) | Power Consumption (HP) | Noise Level (dB) | Weight (lbs) |

|---|---|---|---|---|---|

| Positive Displacement Pump | 28 | 5 | 2 | 70 | 50 |

| Regenerative Blower | 25 | 10 | 3 | 65 | 45 |

| Side Channel Blower | 20 | 20 | 5 | 62 | 60 |

| Diaphragm Pump | 26 | 8 | 1.5 | 68 | 40 |

Maintenance and Service Considerations for Long-Term Use

When it comes to vacuum blower pump maintenance, regular checks are essential. Many pumps require oil changes every 500 operating hours, according to industry standards. Neglecting this can lead to reduced efficiency and potential breakdowns. Ensure you monitor the pump's performance regularly. Listen for unusual noises and check for leaks.

Tips: Create a maintenance schedule. It helps you track oil changes and inspections. Keep a log to note issues over time.

Dust and debris can clog filters, impacting airflow. Cleaning or replacing filters should happen every month. Industry reports indicate that clean filters can boost efficiency by up to 20%. However, some users forget this step. This is a critical oversight that can lead to costly repairs.

Tips: Inspect filters during routine checks. A clean pump operates smoother and lasts longer.

Some pumps may show wear after years of use. Regular inspection can help catch small problems before they escalate. Keeping an eye on gasket conditions is equally important. A small leak can lead to significant performance issues. Consistent attention here will yield better long-term results.

Related Posts

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

What is an Oil Vacuum Pump and How Does it Work for Efficient Operations

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

Top 5 Vacuum Blowers for Efficient Industrial Applications in 2023

-

Top 10 Benefits of Using Rotary Vane Vacuum Pumps for Your Applications