- Eng

- Deu

- Fra

The Best Vacuum Blower Pump Solutions for Efficient Performance and Reliability

In today's industrial landscape, the demand for efficient and reliable machinery is at an all-time high. Amidst this pursuit for performance, vacuum blower pumps have emerged as crucial components in a variety of applications, ranging from material handling to environmental control. These devices are designed to create a vacuum by removing air and gases from a designated space, thus enabling various processes to operate smoothly and effectively.

The selection of the right vacuum blower pump is imperative to ensure optimal performance across applications. Factors such as operational efficiency, durability, and maintenance ease play significant roles in determining the suitability of these pumps for specific tasks. As industries increasingly recognize the importance of energy efficiency and cost-effectiveness, the vacuum blower pump stands out as a solution that addresses these needs while maintaining reliability.

In this article, we will explore the best vacuum blower pump solutions available, focusing on their performance characteristics and operational advantages. By understanding these key features, businesses can make informed decisions when it comes to investing in vacuum blower pumps that not only enhance productivity but also contribute to long-term operational success.

The Importance of Vacuum Blower Pumps in Industrial Applications

Vacuum blower pumps play a crucial role in various industrial applications due to their ability to create and maintain low-pressure environments. These pumps are widely used in processes such as material handling, pneumatic conveying, and vacuum packaging, where the removal of air or gases is essential. By efficiently evacuating air from a system, vacuum blower pumps optimize production efficiency, minimize contamination, and enhance product quality. Their reliability ensures that production lines operate smoothly without interruptions caused by equipment failures, thus maintaining operational effectiveness.

Furthermore, the importance of vacuum blower pumps extends to improving energy efficiency within industrial operations. By utilizing advanced designs that maximize airflow and minimize energy consumption, these pumps contribute to reducing operational costs. In industries like food packaging and pharmaceuticals, where maintaining sterility and product integrity is critical, the consistent performance of vacuum blower pumps becomes even more vital. As industries continue to evolve and seek sustainable practices, the role of these pumps in enhancing both performance and reliability cannot be overstated, making them an indispensable component of modern industrial processes.

The Best Vacuum Blower Pump Solutions for Efficient Performance and Reliability

| Feature | Importance | Efficiency Rating | Common Applications |

|---|---|---|---|

| High Flow Rate | Ensures rapid vacuum creation for processes | 95% | Packaging, Food Processing |

| Energy Efficiency | Reduces operational costs | 90% | HVAC Systems, Chemical Processing |

| Low Noise Levels | Improves workplace comfort | 85% | Laboratories, Pharmaceutical Manufacturing |

| Robust Construction | Increases lifespan and reliability | 92% | Mining, Waste Management |

| Variable Speed Control | Allows adaptation to different processes | 88% | Textile, Plastics |

Key Performance Metrics for Evaluating Vacuum Blower Pumps

When evaluating vacuum blower pumps, several key performance metrics are essential for determining efficiency and reliability. One of the primary factors is the pump's airflow rate, which directly impacts the effectiveness of the system's operation. A higher airflow rate typically indicates a pump's ability to handle larger volumes of air, making it suitable for various industrial applications. It's important to consider the specific requirements of an operation to ensure that the pump can meet or exceed those demands.

Another significant metric is the ultimate vacuum level that the pump can achieve. This measure reflects the lowest pressure that can be maintained in the system, influencing the performance in applications requiring deep vacuum conditions. Assessing this metric can help users understand the pump's capability to create and hold vacuums over extended periods. Additionally, factors such as energy efficiency, noise levels, and maintenance needs play critical roles in evaluating the overall performance of vacuum blower pumps, ensuring that operators can choose a solution that aligns with their operational goals while minimizing downtime and operational costs.

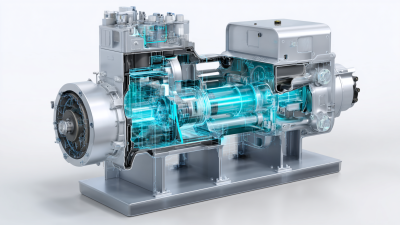

Comparative Analysis of Different Types of Vacuum Blower Pump Technologies

When evaluating vacuum blower pump technologies, it is essential to consider their operational efficiency and reliability across various applications. Recent industry reports suggest that rotary vane blowers offer a solid balance between performance and maintenance, often achieving efficiency levels exceeding 80%. In contrast, positive displacement blowers are favored in applications requiring high vacuum levels, delivering impressive reliability but sometimes at the cost of increased energy consumption. Thus, businesses must assess their specific needs carefully when choosing the right technology.

Tip: Regular maintenance checks, including monitoring seals and filtration systems, can significantly prolong the lifespan of your vacuum blower pump, ensuring consistent performance and reliability over time.

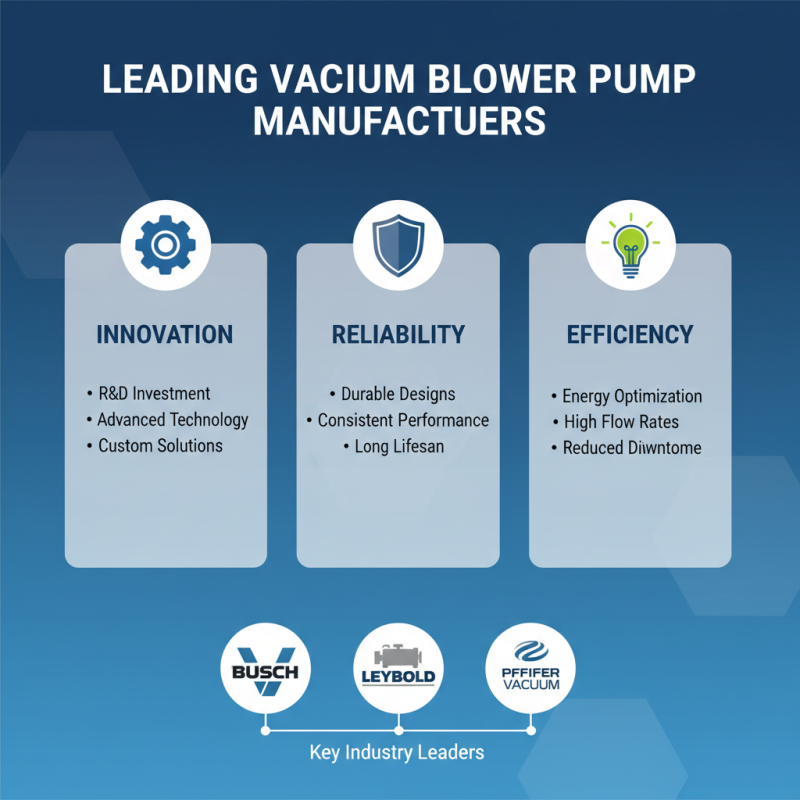

Top Manufacturers of Vacuum Blower Pumps and Their Market Share

When examining the landscape of vacuum blower pumps, it's essential to focus on the leading manufacturers that have consistently delivered high-quality solutions. These top manufacturers differentiate themselves through innovation, reliability, and efficiency, carving out substantial market shares in the vacuum technology sector. They invest heavily in research and development, ensuring that their products meet the evolving demands of various industrial applications.

Moreover, market share distribution among these manufacturers reveals a competitive environment where both established players and emerging companies strive to enhance their product offerings. Companies with a robust presence typically excel in providing comprehensive support and service options, factors that significantly contribute to customer loyalty. As industries increasingly prioritize energy efficiency and sustainability, manufacturers that align their products with these values tend to capture greater market segments, reinforcing their position in the global marketplace.

Future Trends and Innovations in Vacuum Blower Pump Solutions

As industries increasingly prioritize efficiency and sustainability, vacuum blower pump solutions are evolving to meet these demands. Future trends point to advancements in materials science, enabling the production of lighter and more durable components that enhance the performance and reliability of these systems. According to a recent market report, the global vacuum pump market is projected to reach $7.5 billion by 2026, with a significant portion attributed to innovations in blower technologies such as energy-efficient designs and smart control systems.

Another key innovation includes the integration of IoT (Internet of Things) technologies to provide real-time monitoring and predictive maintenance capabilities. This approach not only minimizes downtime but also improves long-term reliability by predicting failures before they occur, thereby ensuring optimal performance. An estimated 30% increase in efficiency has been observed in systems that implement such smart technologies, showcasing the competitive edge they provide in various application sectors.

Tips: When selecting a vacuum blower pump, consider systems equipped with smart sensors to monitor operational parameters. Additionally, evaluating the materials used in the pump can indicate its longevity and resilience. Lastly, consult with industry experts to stay updated on emerging technologies, ensuring that your investments are aligned with future trends.

The Best Vacuum Blower Pump Solutions for Efficient Performance and Reliability

This chart displays the performance metrics of vacuum blower pump solutions, indicating their efficiency, reliability, noise levels, and energy consumption. Monitoring these factors is crucial for evaluating the effectiveness and future trends in vacuum blower pump innovations.

Related Posts

-

Top 5 Vacuum Blowers for Efficient Industrial Applications in 2023

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

How to Choose the Right Oil Pumps for Your Industrial Needs

-

Understanding the Future of Energy: How Oil Pumps Power the Transition to Renewable Resources