- Eng

- Deu

- Fra

Best Septic Vacuum Pump for Efficient Waste Management?

Efficient waste management is crucial for maintaining public health and environmental safety. The septic vacuum pump plays a vital role in this process. According to industry reports, improper waste management leads to significant health hazards. Nearly 8% of the population relies on septic systems for wastewater treatment. Those systems require regular maintenance to function effectively.

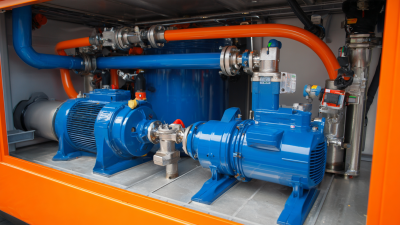

Septic vacuum pumps are essential tools for removing waste from septic tanks. They ensure that systems operate smoothly and prevent backups. A well-functioning septic vacuum pump can improve efficiency by 30%. However, choosing the right model is not always straightforward. Factors such as pump capacity, suction power, and durability must be considered.

Not all septic vacuum pumps meet performance expectations. Some models fail to provide adequate suction or durability. This highlights the need for careful research and selection. A well-informed choice can enhance waste management practices significantly.

Overview of Septic Vacuum Pumps and Their Importance in Waste Management

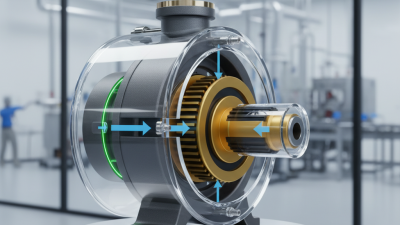

Septic vacuum pumps play a crucial role in waste management systems. These devices help efficiently remove and transport sewage and wastewater from septic tanks. Proper maintenance of septic systems is essential for public health. When a septic tank fills, a vacuum pump ensures the waste is evacuated promptly, reducing the risk of overflow or backflow.

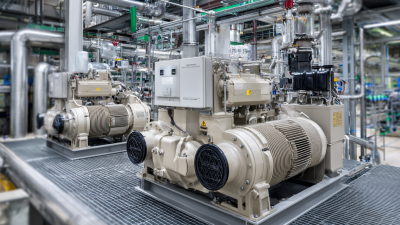

Selecting the right vacuum pump can be challenging. Factors like tank size and waste type matter greatly. Many users underestimate the importance of pump capacity. A pump that’s too small may not handle the workload effectively. Conversely, an overly powerful pump can damage tanks by creating excessive suction. Regular checks and assessments are important for performance and safety.

The operational efficiency of a septic vacuum pump depends on operator experience. Many face difficulties in learning the correct techniques. An inexperienced operator can lead to system failures. It’s vital to invest time in understanding the equipment and procedures. Each septic system is unique, and each pump requires different approaches. Observing and learning from each pumping session can enhance future operations.

Best Septic Vacuum Pump for Efficient Waste Management

| Feature | Description | Importance |

|---|---|---|

| Pump Capacity | Ranging from 500 to 3000 gallons per hour | Ensures timely waste removal and service efficiency |

| Design | Compact, portable designs available | Facilitates easier transportation and maneuverability |

| Power Source | Electric or gas-powered options | Flexibility based on site requirements |

| Vacuum Level | High vacuum levels from 15 to 27 inches of mercury | Efficient removal of solid and liquid waste |

| Durability | Constructed from heavy-duty materials | Longer lifespan and lower maintenance costs |

| Safety Features | Overload protection and automatic shut-off | Ensures operator safety and prevents accidents |

Key Features to Consider When Selecting a Septic Vacuum Pump

When selecting a septic vacuum pump, consider several key features. The pump’s capacity is critical. Look for units that can handle a minimum of 500 gallons per minute (GPM). This rating ensures efficiency in waste removal. A higher capacity can reduce pump operation time, leading to lower labor costs and increased productivity.

Moreover, pump design matters significantly. A self-priming design can enhance performance, especially in challenging environments. Research indicates that self-priming pumps can save up to 30% on energy costs. Make sure the pump is easy to maintain. Frequent servicing can lead to downtime, impacting overall operations.

Check the suction lift capability, which typically ranges from 20 to 30 feet. This range is essential for effective waste collection. Additionally, consider the material quality of the pump. Materials like stainless steel can offer durability and resist corrosion. Many industry standards suggest that proper material choice can extend pump life by up to 50%. Keep these factors in mind to ensure efficient waste management.

Best Septic Vacuum Pump for Efficient Waste Management

Different Types of Septic Vacuum Pumps: Pros and Cons

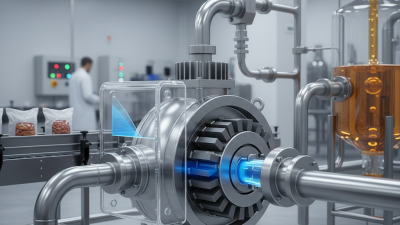

When it comes to efficient waste management, choosing the right septic vacuum pump is crucial. Various types exist, each with distinct pros and cons. The two primary types include positive displacement pumps and centrifugal pumps.

Positive displacement pumps excel in high-viscosity environments. They efficiently handle thick waste, ensuring minimal clogging. However, they can be more expensive and may require more maintenance.

Centrifugal pumps are more affordable and commonly used. They are great for liquid waste, providing good flow rates. Yet, they struggle with solids and thick sludge. A report by the Environmental Protection Agency noted that improper septic system maintenance can lead to significant environmental issues. So, understanding these differences is vital for effective waste management.

Tips: Regularly inspect your pump system for signs of wear. Schedule maintenance to prevent costly repairs. Choose pumps based on the specific waste type in your system. Balancing efficiency and cost is essential for long-term success. Remember, investing in quality equipment can save money in the long run.

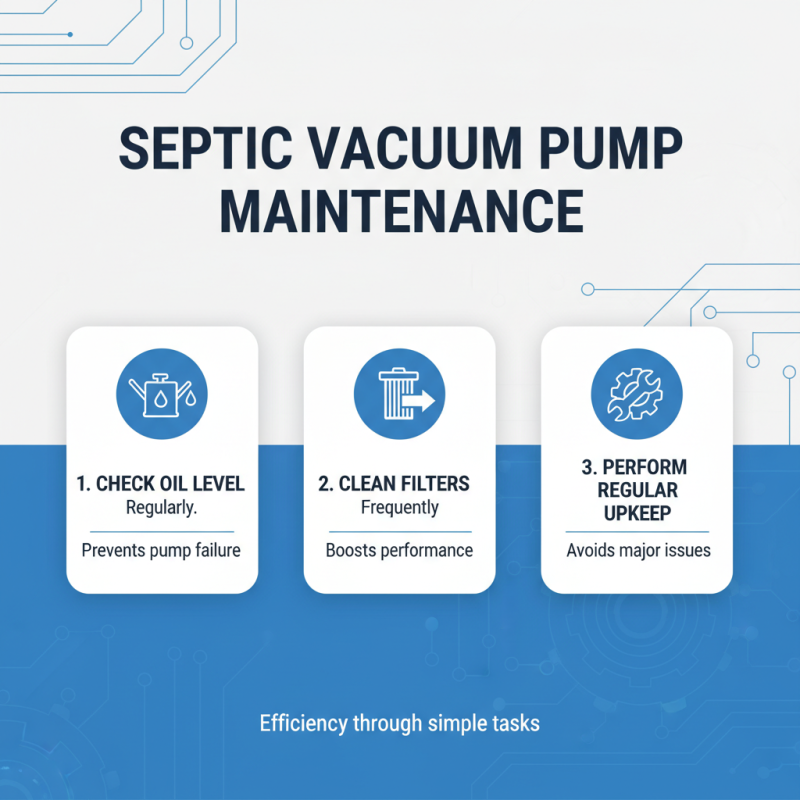

Maintenance Tips for Ensuring Optimal Performance of Septic Vacuum Pumps

When it comes to septic vacuum pumps, regular maintenance is crucial for efficiency. Often overlooked, simple tasks can prevent larger issues. Check the oil level regularly. Low oil can lead to pump failure. Clean filters frequently; dirty filters reduce performance and can cause damage.

Monitor the pump's performance. Listen for unusual sounds. Strange noises may indicate a problem. Inspect hoses for leaks; leaks can be costly and harmful. If you notice a decrease in suction, it might be time for deeper inspection. Keeping an eye on these details ensures the pump operates at its best.

Sometimes, operators might neglect certain signs. For example, a vibrating pump often suggests air leaks. Address these signs promptly. Regular servicing can make all the difference. Ensure you’re taking notes on each maintenance action. This record can help track recurring issues. Overall, a proactive approach can prevent unexpected breakdowns.

Top Brands and Models of Septic Vacuum Pumps in the Market Today

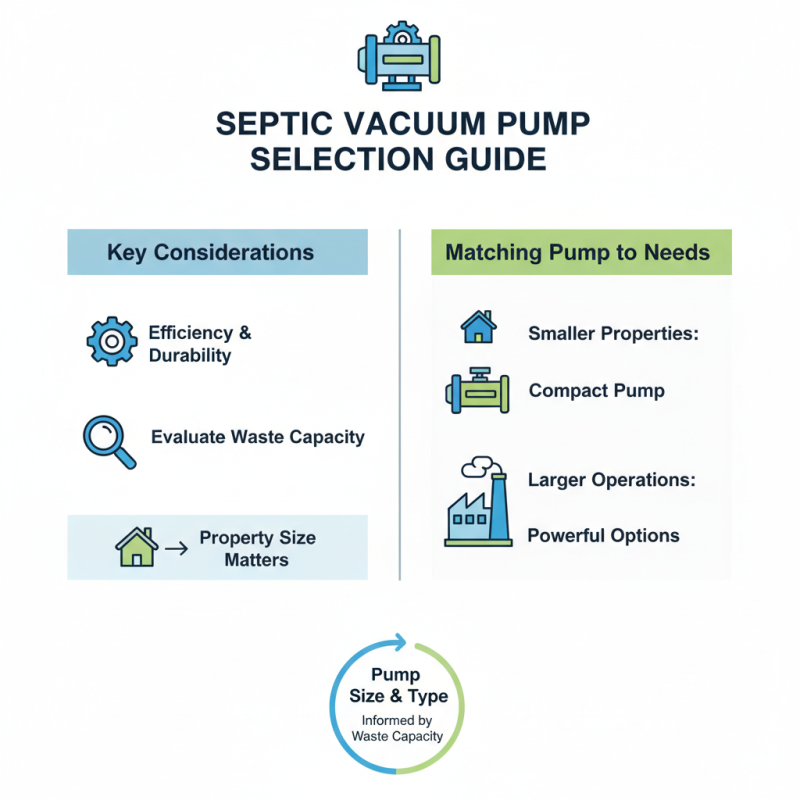

When choosing a septic vacuum pump, consider the efficiency and durability of the equipment. Different models cater to various needs. For smaller properties, a compact pump might be sufficient. Larger operations require more powerful options. Evaluating your waste capacity is crucial. It informs the pump size and type you will need.

Tips: Always check for user reviews. They provide real-life experiences. Researching models can save you from future frustrations. Maintenance is also key. Regularly inspect your pump to ensure it functions well. Look for signs of wear and tear.

Several brands offer a range of features. Some models have advanced filtration systems. Others focus on energy efficiency. This diversity helps match your specific needs. It’s essential to find a model that fits your budget and requirements. Don’t rush your decision. Take the time to weigh the pros and cons of each model to ensure optimal performance.

Related Posts

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

What is an Oil Vacuum Pump and How Does it Work for Efficient Operations

-

Top 10 Benefits of Using Rotary Vane Vacuum Pumps for Your Applications

-

Why Choose a Rotary Vane Vacuum Pump for Your Industrial Applications