- Eng

- Deu

- Fra

2026 Best Rotary Vane Vacuum Pump Options for Every Need?

In the domain of vacuum technology, rotary vane vacuum pumps hold a prominent place. Known for their reliability and efficient performance, these pumps cater to diverse applications. Dr. Emily Carter, a leading expert in vacuum systems, has noted, “Choosing the right rotary vane vacuum pump can significantly impact operational success.”

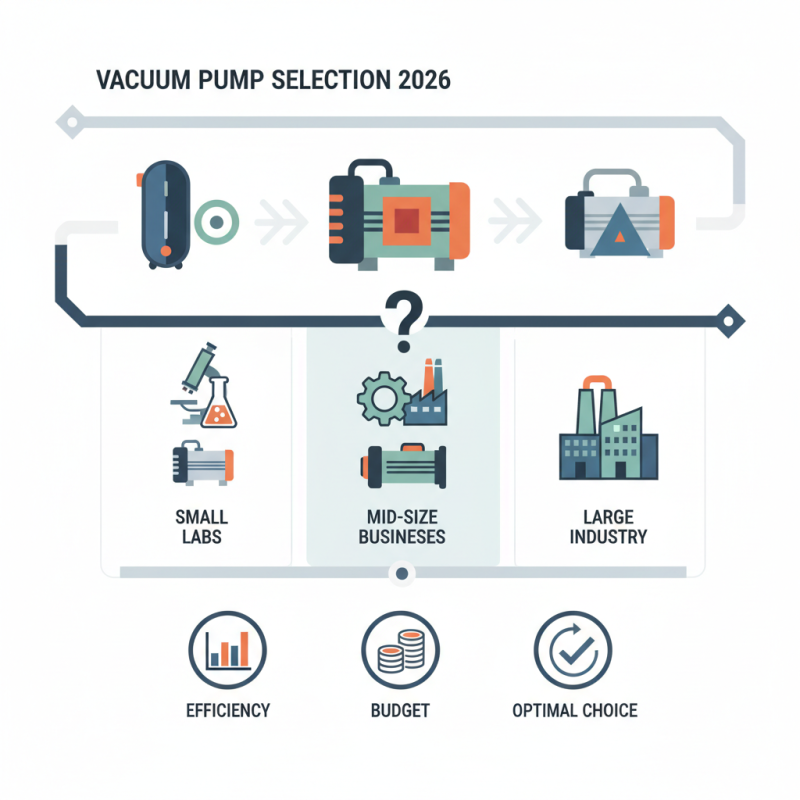

For many businesses, selecting a vacuum pump is not just about power; it involves understanding specific needs. The variety of options can be overwhelming. Should one choose a quiet model or a heavy-duty version? Each choice comes with distinct advantages and trade-offs. Some small labs may find basic models sufficient, while large-scale industries require robust systems.

Understanding this landscape is essential. Users must reflect on their requirements carefully. Often, the most effective rotary vane vacuum pump is not the most expensive. It is the one that aligns with the precise needs of the application at hand. As we explore the best options for 2026, considerations such as efficiency, budget, and pump longevity will shape the decision-making process.

2026 Overview of Rotary Vane Vacuum Pumps and Their Applications

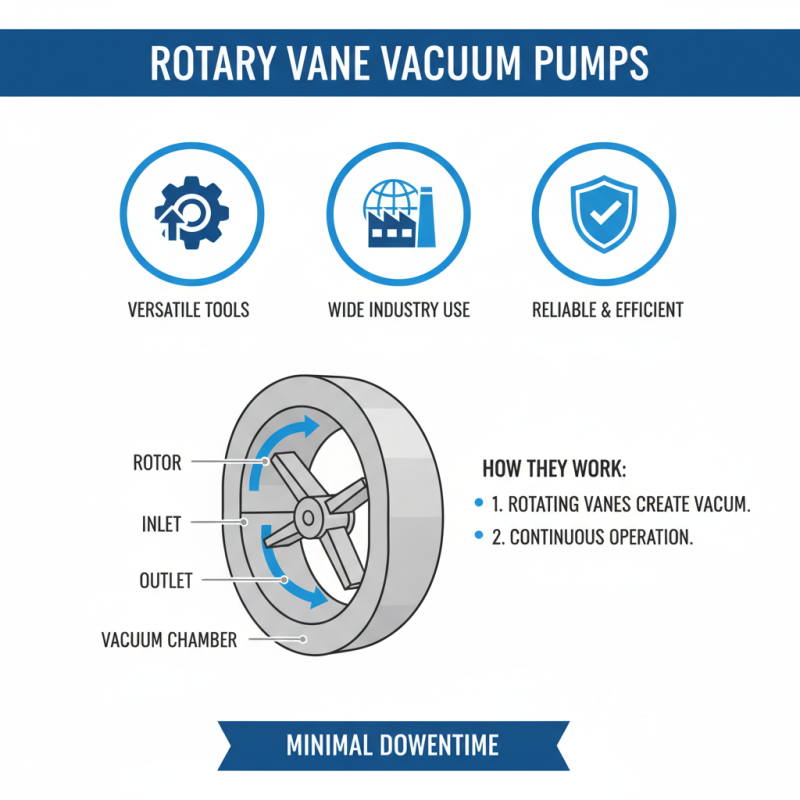

Rotary vane vacuum pumps are versatile tools. They are widely used in various industries. These pumps are known for their reliability and efficiency. They work by using rotating vanes to create a vacuum. This design allows for continuous operation with minimal downtime.

Applications for rotary vane vacuum pumps vary significantly. They are essential in laboratory environments. In these settings, they help in filtration and drying processes. They also play a crucial role in medical equipment, ensuring proper functioning. In packaging, these pumps assist in maintaining product freshness. It's worth noting that while effective, they can sometimes require maintenance due to wear and tear.

However, choosing the right pump can be tricky. Not all models perform equally well across different tasks. Users should consider specific needs before making a decision. Understanding the requirements of your application is vital. Sometimes, a pump may not deliver the expected performance. This can lead to inefficiencies in operations. Being aware of these limitations ensures better outcomes. Investing time in research pays off in the long run.

Key Factors to Consider When Selecting a Rotary Vane Vacuum Pump

When selecting a rotary vane vacuum pump, several key factors come into play. Consider the application you have in mind. Different tasks require varying vacuum levels. Some processes may need a deep vacuum, while others work well with a medium vacuum. Understanding your specific needs will guide you toward the right model.

The size and power of the pump are crucial as well. A more powerful pump can extract air faster. However, too much power may waste energy. Think about the power source available to you. Some pumps rely on electricity, while others may use compressed air. Evaluate what suits your workspace best.

Noise levels are another important consideration. Some rotary vane pumps produce significant noise during operation. If noise is a concern, research quieter options. Maintenance needs also vary between models. Some require regular oil changes, while others need minimal upkeep. This can impact your choice, especially if you prefer low-maintenance solutions.

Top Brands Dominating the Rotary Vane Vacuum Pump Market in 2026

The rotary vane vacuum pump market in 2026 is seeing significant growth. Various brands are making their mark with innovative designs and efficient technology. Users are now facing challenges when choosing the right pump. Preferences depend on specific needs, including pump size and suction capacity.

Leading brands stand out through reliability and performance. Many offer models suitable for industrial and commercial applications. However, some users report dissatisfaction due to noise levels or maintenance frequency. This factor prompts deeper consideration of options available.

Investing in a rotary vane vacuum pump is no small decision. Prospective buyers should analyze their requirements carefully. Functionality is critical, yet price cannot be overlooked. Listening to user feedback can help bridge the gap between expectation and reality. While choices abound, informed decisions can lead to long-term satisfaction.

Performance Metrics: Comparing Efficiency and Reliability of Different Models

When selecting a rotary vane vacuum pump, performance metrics are crucial. Efficiency often comes down to how quickly and effectively a model completes tasks. A well-performing pump achieves higher vacuum levels while consuming less energy. Many users overlook energy efficiency. This oversight can lead to higher operational costs over time.

Reliability is another vital aspect. It involves the lifespan of the pump and its consistent performance under varying conditions. Data from user experiences often highlight how certain models fail after extensive use. These failures can lead to costly downtimes. Users should consider maintenance needs, as complex systems can be tedious to service.

In addition, noise levels can affect user experience. Some pumps operate quietly, while others create disruptions in work environments. Buyers often undervalue the importance of minimal noise. This can impact productivity and comfort. Evaluating these metrics helps potential buyers avoid frustration later and choose wisely.

2026 Best Rotary Vane Vacuum Pump Options for Every Need

| Model | Max Vacuum (inHg) | Flow Rate (CFM) | Motor Power (HP) | Noise Level (dB) | Weight (lbs) | Price (USD) |

|---|---|---|---|---|---|---|

| Model A | 28 | 5 | 1.5 | 75 | 50 | 450 |

| Model B | 27 | 6 | 2.0 | 70 | 55 | 500 |

| Model C | 29 | 4.5 | 1.0 | 80 | 45 | 400 |

| Model D | 30 | 7 | 3.0 | 72 | 65 | 600 |

| Model E | 26 | 5.5 | 1.75 | 68 | 52 | 480 |

Future Trends in Rotary Vane Vacuum Pump Technology and Innovation

The future of rotary vane vacuum pumps is exciting. Innovations are reshaping the industry, making these pumps more efficient and versatile. One trend is the shift towards energy-efficient designs. Manufacturers are focusing on ways to reduce power consumption while maintaining high performance. This change not only helps the environment but also lowers operational costs for users.

Another area of advancement is in materials. New composite materials are being developed. These materials can withstand higher pressures and temperatures, improving pump durability. However, they might also raise the cost of production. Users should weigh the benefits against potential price increases.

Tip: Always evaluate the total cost of ownership. Sometimes cheaper models may lead to higher expenses over time.

Digital integration is also on the rise. Smart technology can monitor pump performance in real time. This allows for predictive maintenance, which minimizes downtime. Users can address issues before they escalate. But adopting new technology requires investment and training.

Tip: Stay updated on new technologies. Consider training sessions for staff to ensure smooth adaptation.

In this rapidly changing landscape, being informed is crucial. The best choices depend on current needs and future trends. It’s essential to reflect on how advancements can either help or hinder your operations.

Related Posts

-

2026 How to Choose the Right Rotary Vane Vacuum Pump for Your Needs?

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

2025 Top 5 Vacuum Blower Pumps to Boost Your Industrial Efficiency