- Eng

- Deu

- Fra

Top 5 Best High Vacuum Pumps for Efficient Performance?

High vacuum pumps play a crucial role in various industries, from semiconductor manufacturing to scientific research. According to Dr. Emily Carter, a recognized expert in vacuum technology, “Choosing the right high vacuum pump can make or break your experiment.” Her insight underscores the importance of efficiency and reliability in pump selection.

The market offers a variety of high vacuum pumps, yet finding the best-performing models can be challenging. Many users encounter issues with pump longevity and operational efficiency. This often leads to frustration in achieving desired vacuum levels. It’s essential to understand each pump's specifications and how they align with your specific requirements.

Selecting a high vacuum pump should involve careful consideration. Each application is unique, and what works for one task may fail in another. Reflecting on experiences in the field can reveal gaps in understanding. Professionals must continuously evaluate both pump performance and their own processes to ensure optimized results.

Overview of High Vacuum Pumps and Their Importance

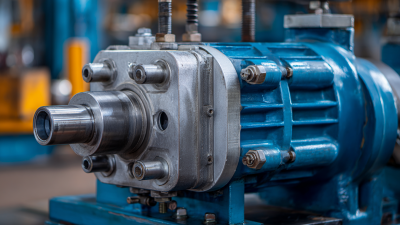

High vacuum pumps play a crucial role in various industries. They efficiently evacuate air and other gases from sealed systems. This process creates high purity environments for scientific experiments, semiconductor manufacturing, and even in the medical field. High vacuum pumps ensure that processes remain free from contaminants. Without these pumps, achieving the desired vacuum levels would be nearly impossible.

Using high vacuum pumps efficiently requires understanding their operation. Consider using proper maintenance practices. Regular checks can prevent wear and tear. Monitor pump performance consistently. Early detection of issues can save time and money. Be mindful of system compatibility, too. Not all pumps fit every application.

When selecting a high vacuum pump, do your homework. Assess specific needs and requirements first. Understand the environment where it will be used. If installation seems complicated, don't hesitate to seek expert advice. Proper installation affects overall performance significantly. A well-chosen pump ensures not only efficiency but also operational stability.

Key Features to Consider When Choosing a High Vacuum Pump

When choosing a high vacuum pump, several key features stand out. First, consider the pump's ultimate vacuum level. This specification indicates how low the pressure can go. A better ultimate vacuum level ensures more efficient performance in various applications. Check if it meets your specific requirements.

Next, look at the pumping speed. This measures how fast the pump can remove gas from a chamber. A higher pumping speed means quicker evacuation times. However, if it's too high for your application, it might create issues like backstreaming. Balance is crucial here.

Finally, evaluate the maintenance needs. Some pumps demand frequent upkeep, while others are more user-friendly. High-maintenance pumps can lead to downtime. Think about your working environment and how this factor fits in. Even the best pump can falter if not properly cared for. This can lead to inefficiency and lost productivity. Reflect on these aspects when making your choice.

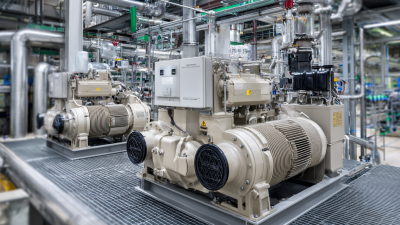

Top 5 High Vacuum Pumps for Industrial and Laboratory Use

When choosing high vacuum pumps for industrial and laboratory use, efficiency is crucial. These pumps help achieve low pressure environments necessary for various applications. Their design and functionality can greatly impact your projects. Quality vacuum pumps maintain a stable vacuum level. They minimize contamination risks and enhance experimental accuracy.

**Tip:** Always check the pump's ultimate vacuum rating. This number indicates how low the pump can go. Make sure it aligns with your specific requirements. A pump can fail to perform well if not paired correctly with your system.

Consider maintenance schedules for your high vacuum pumps. Routine checks can prevent unexpected downtime. Regular oil changes and filter replacements are essential. A neglected pump could lead to inaccuracies in processes.

**Tip:** Train your team on proper pump handling. Awareness of the pump’s limits is vital. This approach keeps your operations smooth and efficient. When everyone understands their equipment, the risk of errors decreases significantly.

Comparison of Performance Metrics for Selected High Vacuum Pumps

When selecting high vacuum pumps, performance metrics are crucial. These include pumping speed, ultimate pressure, and gas compatibility. A pump with high pumping speed quickly evacuates gas from a chamber. However, this can sometimes lead to increased noise, which might be a concern in sensitive environments. It's vital to find a balance.

Ultimate pressure is another key aspect. It indicates how low a pump can go. Some pumps might not reach the expected levels in real-world conditions. This gap can lead to inefficiencies. Users might also face challenges with gas types. Certain pumps work well with specific gases but struggle with others.

In practice, efficiency can vary. For some users, a pump may seem ideal in theory but underperform in specific setups. Maintenance cannot be overlooked. Regular checks are essential to keep performance consistent. Pumps can experience wear that affects their metrics. Balancing these factors often requires trial and error. This ongoing process is essential for optimizing performance.

Top 5 Best High Vacuum Pumps for Efficient Performance

| Pump Type | Ultimate Vacuum (torr) | Pumping Speed (L/s) | Power Consumption (W) | Weight (kg) |

|---|---|---|---|---|

| Rotary Vane Pump | 10^-3 | 40 | 350 | 25 |

| Scroll Pump | 10^-6 | 25 | 200 | 15 |

| Diaphragm Pump | 10^-4 | 10 | 150 | 5 |

| Turbomolecular Pump | 10^-10 | 200 | 500 | 30 |

| Cryogenic Pump | 10^-8 | 15 | 600 | 50 |

Maintenance Tips to Ensure Long-lasting Efficiency of Vacuum Pumps

Maintaining vacuum pumps is crucial for their efficient performance. Regular checks can extend the life of the pump significantly. One vital aspect is monitoring the oil level. If it’s low, the pump could overheat. Always ensure that the oil is clean. Contaminated oil can cause wear and tear on internal components. Replace oil according to the manufacturer’s recommendation to avoid unexpected breakdowns.

Cleaning filters and keeping vents clear is also essential. Dust and debris can clog the system, impacting efficiency. A thorough cleaning every few months can help. Listen for unusual noises. Strange sounds often signal that something is wrong. Addressing these issues early can save time and money.

Furthermore, inspect the seals regularly. Worn-out seals can lead to leaks, reducing performance. Regular inspections can help spot problems before they escalate. Noticing small issues now can prevent larger repairs later.

Related Posts

-

What is an Oil Vacuum Pump and How Does it Work for Efficient Operations

-

What is a Vacuum Blower Pump and How Does It Work in Industry

-

2026 How to Choose the Right Rotary Vane Vacuum Pump for Your Needs?

-

How to Choose the Best Heavy Duty Vacuum Pump for Your Needs?

-

How to Choose the Right Vacuum Blower Pump for Your Needs

-

Understanding the Efficiency and Applications of Rotary Vane Vacuum Pumps in Modern Industries