- Eng

- Deu

- Fra

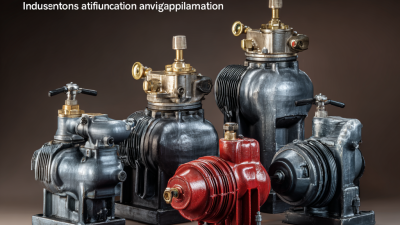

Top 10 Benefits of Using Rotary Vane Pumps for Your Applications

In the realm of fluid transfer technologies, rotary vane pumps have emerged as a cornerstone for diverse applications, offering a unique blend of efficiency and versatility. As noted by industry expert Dr. Samantha Greene, a leading authority in fluid dynamics, "The ability of rotary vane pumps to maintain a steady flow under varying conditions makes them indispensable in many sectors." This statement highlights the fundamental advantages of rotary vane pumps, from automotive to manufacturing processes, where reliability and performance are paramount.

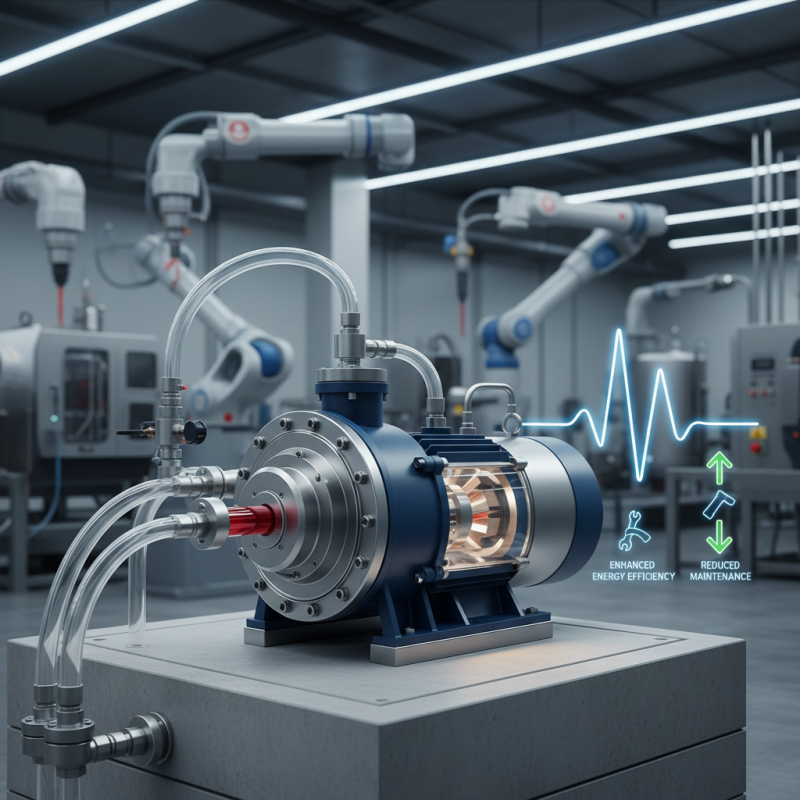

The benefits of utilizing rotary vane pumps extend beyond mere functionality; they encapsulate cost-effectiveness, reduced maintenance requirements, and enhanced energy efficiency. Their design allows for smooth operation, which minimizes pulsation and vibration, ultimately contributing to the longevity of both the pump and the system it serves. Moreover, the adaptability of rotary vane pumps to handle a wide range of fluids, including those with varying viscosities, showcases their versatility across multiple industries.

As we delve into the top ten benefits of using rotary vane pumps, it becomes evident that these devices not only meet operational demands but also stand as pivotal components in optimizing performance across diverse applications. Understanding these advantages can aid businesses in making informed decisions that enhance efficiency and productivity in their operations.

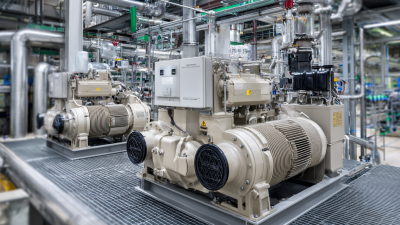

Key Advantages of Rotary Vane Pumps in Various Industries

Rotary vane pumps have emerged as essential equipment across various industries, owing to their unique design and operational efficiency. One of the key advantages of these pumps is their ability to provide a consistent flow rate, which is crucial in applications ranging from HVAC systems to food processing. Their simplicity in construction allows for easy maintenance and reduced downtime, making them a preferred choice for manufacturers aiming for maximum productivity.

In the automotive industry, rotary vane pumps are valued for their capacity to handle both liquids and gases, making them versatile for different applications, including fuel transfer and air conditioning systems. Their robust design allows them to withstand harsh conditions, ensuring longevity and reliability. Additionally, the low noise level during operation makes them suitable for environments where sound pollution is a concern.

Tips: When selecting a rotary vane pump, consider the specific requirements of your application, such as pressure and temperature ranges. Proper installation and regular maintenance can significantly enhance the pump's performance and lifespan. Moreover, consulting with industry experts can provide insights into optimizing the pump’s capabilities for your unique needs, ensuring you maximize the benefits these pumps offer.

Improved Efficiency of Fluid Transfer with Rotary Vane Pumps

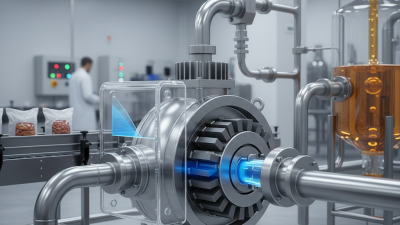

Rotary vane pumps are increasingly recognized for their efficiency in fluid transfer applications. Their design enables consistent fluid movement with minimal pulsation, which is a significant advantage when precision is paramount. The rotor's rotation creates a vacuum that effectively draws in the fluid, leading to smoother and more effective transfer processes. This not only improves operational efficiency but also reduces wear and tear on the system components, ultimately lowering maintenance costs.

**Tips:** When selecting a rotary vane pump, consider the viscosity and nature of the fluid being transferred. This is crucial because different fluids can impact the pump's performance and lifespan. Additionally, ensure proper installation and regular maintenance checks, as these steps are vital for maintaining optimal efficiency and minimizing any potential downtime in your operations.

Another advantage of rotary vane pumps is their versatility in handling a variety of fluids, including those that require gentle handling like food products or delicate chemicals. The ability to operate at different pressures also makes these pumps suitable for a wide range of applications, from industrial processing to laboratory use. By understanding the unique features of rotary vane pumps, users can significantly enhance their fluid transfer processes while ensuring energy efficiency and reliability.

**Tips:** Always operate within the pump's specified pressure range to avoid any unexpected issues. Monitoring the performance and making adjustments as needed can further enhance efficiency, allowing your operations to run smoothly and effectively.

Top 10 Benefits of Using Rotary Vane Pumps for Your Applications

| Benefit | Description | Application Areas |

|---|---|---|

| High Efficiency | Rotary vane pumps provide improved efficiency in fluid transfer, reducing energy consumption. | Hydraulics, Tank Systems |

| Versatility | Suitable for a wide range of fluids, including viscous liquids and gases. | Food Processing, Chemical Industry |

| Compact Design | Space-efficient design allows easy installation in limited spaces. | Laboratories, Mobile Applications |

| Low Maintenance | Requires less frequent maintenance compared to other pump types. | Industrial Processes, Water Treatment |

| Pulsation-Free Flow | Ensures a smooth and consistent flow, beneficial for sensitive applications. | Pharmaceuticals, Cosmetics |

| Durability | Built to withstand harsh environments, ensuring long operational life. | Mining, Oil and Gas |

| Cost-Effective | Lower operational costs through energy savings and reduced downtime. | Construction, Automotive |

| Wide Range of Flow Rates | Able to handle varying flow rates, which enhances versatility in applications. | Chemical Processing, Agricultural |

| Noise Reduction | Quieter operation compared to other pump types, improving working conditions. | HVAC Systems, Residential |

| Customizable Solutions | Can be tailored to meet specific operational requirements and fluid characteristics. | Specialty Manufacturing, R&D |

Versatility of Rotary Vane Pumps for Multiple Applications

Rotary vane pumps are known for their versatility, making them ideal for a wide range of applications across various industries. From food processing and automotive to pharmaceuticals and chemical engineering, these pumps excel in situations requiring precise monitoring of flow rates and pressure. According to a report by the Pumps and Systems Association, the global positive displacement pump market, including rotary vane technology, is projected to reach $15 billion by 2026. This growth indicates a rising recognition of the advantages provided by these pumps in different operational scenarios.

One notable benefit of rotary vane pumps is their ability to handle not just liquids but also gases, making them suitable for applications in vacuum systems and air handling. Their simple design allows for easy maintenance and longevity, which is a crucial consideration in industries where downtime can be costly. A study published in the Journal of Mechanical Engineering highlights that rotary vane pumps can achieve efficiency rates exceeding 90%, ensuring minimal energy losses during operation.

**Tip:** When selecting a rotary vane pump, consider the specific requirements of your application, including viscosity, flow rate, and operating temperature. This will help in choosing the right model that maximizes efficiency and longevity.

Another advantage lies in their compact size. Rotary vane pumps can be easily integrated into existing systems without occupying substantial space, making them suitable for constrained environments. Additionally, they operate quietly, thereby reducing noise pollution in workplaces that demand a quieter operational background. As technology advances, the adaptability of rotary vane pumps continues to be enhanced, paving the way for innovative applications across various industries.

**Tip:** Regular maintenance checks, such as inspecting the vanes for wear and tear, will not only prolong the lifespan of the pump but also maintain optimal performance levels in your applications.

Lower Maintenance Costs Associated with Rotary Vane Pumps

Rotary vane pumps are increasingly popular in various industrial applications, primarily due to their efficiency and reliability. One of the standout advantages of using rotary vane pumps is the significantly lower maintenance costs associated with their operation. Unlike other pump types, rotary vane pumps have fewer moving parts, which translates to less wear and tear over time. This simplicity in design reduces the frequency of breakdowns, leading to less downtime and lower repair expenses.

Furthermore, the materials used in rotary vane pumps are often chosen for their durability and resistance to corrosion. This resilience not only extends the lifespan of the pumps but also minimizes the need for regular replacement of components. Maintenance can often be performed with simple inspections and occasional lubrication, rather than extensive overhauls typically required by more complex pumping systems. As a result, companies can allocate resources more efficiently, focusing on productivity rather than ongoing repair costs, which ultimately enhances overall operational efficiency.

Top 10 Benefits of Using Rotary Vane Pumps

This chart illustrates the top 10 benefits of using rotary vane pumps, with a focus on their lower maintenance costs and other advantages that enhance their application in various industries.

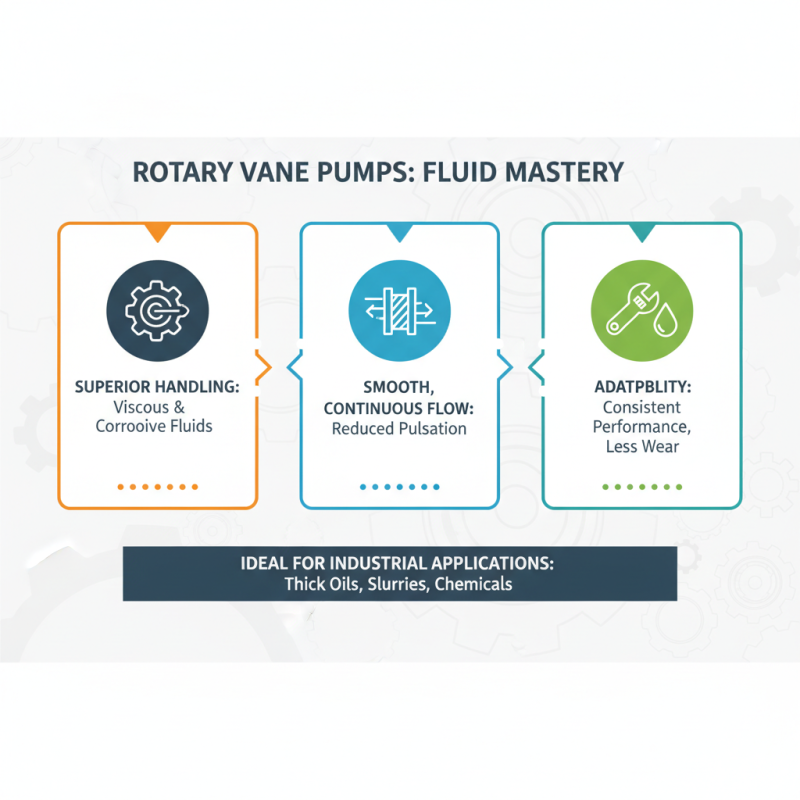

Enhanced Performance in Handling Viscous and Corrosive Fluids

Rotary vane pumps are increasingly recognized for their superior capabilities in handling viscous and corrosive fluids, making them an ideal choice for various industrial applications. Their design allows for a smooth, continuous flow, significantly reducing pulsation and enhancing overall performance when working with dense materials. The vanes within the pump adjust to the fluid’s viscosity, ensuring consistent operation under varying conditions, which is crucial for industries dealing with thick oils, slurries, or other high-viscosity substances. This adaptability translates into less wear and tear, promoting longer service life and lower maintenance costs.

Furthermore, rotary vane pumps can also efficiently manage corrosive fluids, thanks to their robust construction and the availability of materials that resist chemical degradation. This quality is particularly important in sectors such as chemical processing, wastewater treatment, and food production, where the ability to handle aggressive substances without compromising pump performance is essential. By utilizing these pumps, businesses can ensure operational efficiency while maintaining safety and reliability, ultimately enhancing productivity and reducing downtime. The versatility and durability of rotary vane pumps position them as a reliable solution for fluid transfer in challenging environments.

Related Posts

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

-

Why Choose a Rotary Vane Vacuum Pump for Your Industrial Applications

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

Why Oil Pumps Are Essential for Efficient Fluid Management in Industrial Applications

-

What is an Oil Vacuum Pump and How Does it Work for Efficient Operations

-

10 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs