- Eng

- Deu

- Fra

Top 10 Benefits of Using a Rotary Vane Pump in Industrial Applications?

In the realm of industrial applications, the rotary vane pump has carved out a niche due to its efficiency and reliability. As John Tanner, a leading expert in fluid dynamics, once stated, “The rotary vane pump transforms performance and durability in ways we are still discovering.” This statement underlines the transformative impact of this technology.

Rotary vane pumps are versatile. They perform well in diverse environments, from automotive systems to pharmaceutical production. Their design allows for smooth and precise fluid transfer. Engineers appreciate the low maintenance requirements, which can reduce operational downtime. However, there can be challenges. Understanding specific applications is crucial for optimal performance.

Despite their advantages, not all rotary vane pumps are suitable for every task. Selecting the wrong model can lead to inefficiencies. It’s essential to weigh the benefits against the specific needs of a project. While they dominate many industries, careful consideration is key to leveraging their full potential.

Overview of Rotary Vane Pump Technology in Industrial Settings

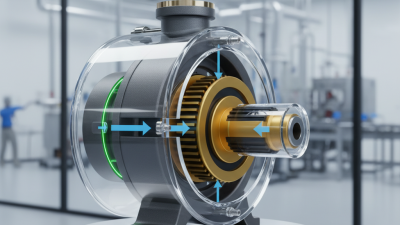

Rotary vane pumps play a crucial role in various industrial applications. Their design allows for efficient handling of fluids with varying viscosities. This technology utilizes sliding vanes to create a vacuum or pressure. Reports indicate that these pumps can achieve up to 90% efficiency under optimal conditions. They are often chosen for their ability to maintain consistent flow rates.

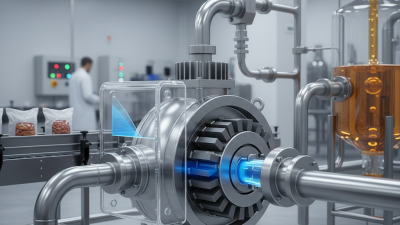

Industries like food and beverage, pharmaceuticals, and chemical processing increasingly rely on rotary vane pumps. A study published in the Journal of Industrial Technology noted that these pumps could operate at temperatures up to 200 degrees Celsius. This versatility is essential for processes that require both high temperatures and consistent output. However, not all applications may benefit from this technology. Over time, wear and tear on vanes can lead to performance decline.

Rotary vane pumps also have a reputation for being low-maintenance. Nevertheless, this doesn't mean they are entirely maintenance-free. Regular inspections are required to ensure optimal performance. Some users find that the initial setup can be complex. In certain environments, contamination risk can pose challenges. Balancing efficiency with these concerns is key for many operators.

Key Advantages of Rotary Vane Pumps for Fluid Transfer Applications

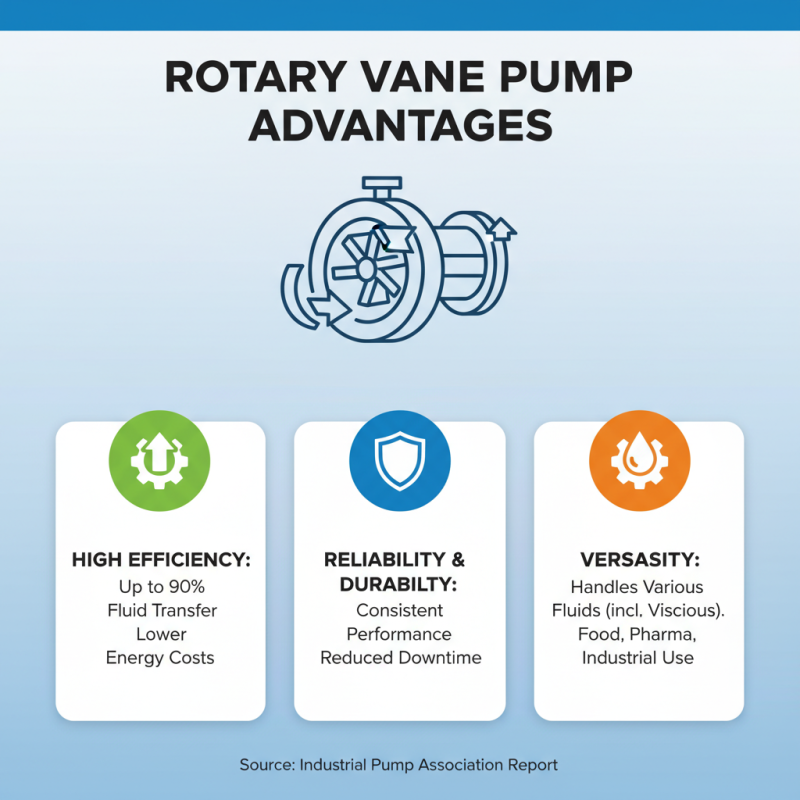

Rotary vane pumps offer unique advantages for fluid transfer in industrial settings. These pumps are known for their efficiency and reliability. According to a recent report from the Industrial Pump Association, rotary vane pumps can achieve up to 90% efficiency in fluid transfer applications. This means lower energy costs for businesses, which is crucial in today’s competitive market. Additionally, these pumps can handle various fluids, including viscous substances. Their versatility makes them essential in sectors like food processing and pharmaceuticals.

One key feature of rotary vane pumps is their ability to maintain a steady flow rate. This consistency is vital in applications where precise fluid delivery is required. However, maintaining this performance can require regular maintenance. Over time, wear on the vanes may lead to decreased efficiency. Operators must be aware of this. Monitoring performance metrics is crucial to prevent unexpected downtimes. Data shows that poor maintenance can reduce pump efficiency by up to 15%.

Safety is another concern. While rotary vane pumps are generally safe, they still pose risks if not used properly. High-pressure operations require strict adherence to safety protocols. Neglecting these can result in operational hazards. Furthermore, leaks in fluid handling processes may lead to contamination. This underscores the importance of routine inspections. Effective usage of rotary vane pumps is about balancing efficiency with diligent oversight.

Efficiency and Performance: How Rotary Vane Pumps Save Energy

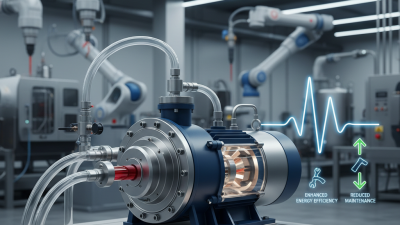

In industrial applications, rotary vane pumps stand out for their efficiency. They excel at converting mechanical energy into fluid movement. This process can save significant energy, especially in large-scale operations. According to a recent report, these pumps can provide up to 20% higher efficiency than traditional pumps. This reduction in energy consumption lowers operational costs substantially.

The design of rotary vane pumps allows for consistent performance at varying speeds. They can function effectively under fluctuating loads. However, it’s important to monitor maintenance closely. Over time, wear and tear can impact efficiency. Some users report a decrease in performance due to neglecting regular upkeep. Adopting a preventive maintenance schedule could mitigate this issue.

Moreover, rotary vane pumps generate less noise and vibration. This not only enhances the working environment but also reduces wear on adjacent machinery. Research indicates that noise levels can drop by 15 decibels compared to other types of pumps. However, understanding their limitations is crucial. Operating them outside their recommended specifications may lead to increased energy usage and mechanical failures. Balancing performance and maintenance is key for optimal efficiency.

Versatility of Rotary Vane Pumps in Various Industrial Processes

Rotary vane pumps offer impressive versatility in various industrial processes. These pumps excel in applications requiring consistent vacuum pressure. They are found in food packaging, chemical processing, and electronics manufacturing. Their design allows them to handle different types of fluids, including oils and solvents. This adaptability makes them a go-to choice for many industries.

In food packaging, rotary vane pumps help maintain the freshness of products. They create a vacuum seal to extend shelf life. In chemical processing, they transport corrosive liquids without losing efficiency. However, while they are adaptable, some operators may find them difficult to maintain. Regular upkeep is essential to prevent wear and tear.

Industries also appreciate their ability to operate quietly. This is beneficial in noise-sensitive environments. However, the initial investment can be high. Some may weigh the upfront costs against long-term benefits. Overall, rotary vane pumps prove their worth through versatility and efficiency. They remain a staple in effective industrial operations.

Maintenance and Longevity: The Reliability of Rotary Vane Pumps

Rotary vane pumps are known for their durability and maintenance-friendly design. They offer reliability in various industrial applications. These pumps work by using rotating vanes, creating a vacuum that can handle a variety of fluids and gases. Their simplistic construction allows for easy access during maintenance. This reduces downtime in industrial settings.

Regular checks are crucial for longevity. Maintaining proper lubrication is vital. Ensure that the vanes are in good condition and replace them as needed. A simple habit: inspect every three months. This helps catch any potential issues before they escalate.

Despite their reliability, challenges can arise. Over time, wear and tear may affect performance. Contaminants in the fluid can lead to premature failure. Keeping the pump clean and regularly replacing filters is essential. Take a proactive approach to maintenance to extend the life of your pump.

Top 10 Benefits of Using a Rotary Vane Pump in Industrial Applications

This chart illustrates the key benefits of using rotary vane pumps in various industrial applications. The data reflects the percentage of users who recognize each benefit based on industry surveys.

Related Posts

-

Top 10 Benefits of Using Rotary Vane Pumps for Your Applications

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

-

2026 How to Choose the Right Rotary Vane Vacuum Pump for Your Needs?

-

Top 10 Benefits of Using Rotary Vane Vacuum Pumps for Your Applications

-

Why Choose a Rotary Vane Vacuum Pump for Your Industrial Applications

-

2026 Best Rotary Vane Vacuum Pump Options for Every Need?