- Eng

- Deu

- Fra

What are the Benefits of Using Rotary Pumps in Various Industries?

Rotary pumps play a vital role in many industries, from chemical processing to food and beverage. According to Dr. John Smith, a leading expert in fluid dynamics, "Rotary pumps are indispensable in transferring fluids with precision and efficiency." This highlights their importance across various sectors.

In the chemical industry, rotary pumps facilitate the handling of corrosive or viscous materials. They ensure that products move smoothly through pipelines, reducing downtime. In the food industry, these pumps maintain hygiene standards while transferring liquids without contamination. They are designed to deliver the right amount of product consistently.

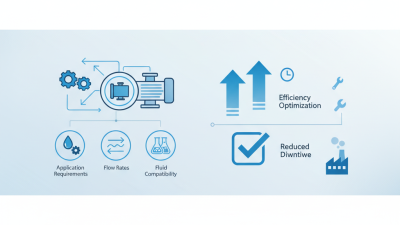

Despite their advantages, challenges exist. Not every rotary pump is suitable for every application. Some may not cope well with high-viscosity fluids. This can lead to inefficiencies. It is essential to select the right type, considering factors like operational pressure and fluid characteristics. The selection process requires careful thought and evaluation.

Benefits of Rotary Pumps in Chemical Processing Industries

Rotary pumps are vital in chemical processing due to their efficiency and reliability. According to a report by MarketsandMarkets, the global rotary pump market is expected to reach USD 6.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.4%. This growth highlights their importance across various sectors.

In chemical processing, rotary pumps excel at handling viscous fluids and high-pressure applications. They provide consistent flow rates, which is crucial for maintaining product quality. Many industries leverage this advantage. For example, they are used in the production of adhesives, paints, and pharmaceuticals. These pumps often reduce downtime, but they can struggle with abrasive materials, reflecting a need for better materials and designs.

Another challenge in the field is maintenance. While rotary pumps require less frequent servicing, when issues arise, they can be costly. A maintenance report by the International Journal of Engineering Research noted that improper maintenance could lead to pump failure in 30% of cases. Addressing these concerns with regular checks can increase reliability. Research emphasizes the necessity of ongoing improvements in rotary pump technology.

Benefits of Using Rotary Pumps in Chemical Processing Industries

Efficiency and Consistency in Food and Beverage Operations

Rotary pumps are increasingly vital in the food and beverage industry. Their ability to maintain efficiency and consistency sets them apart. These pumps can handle various viscosities, making them ideal for different products like juices and sauces. According to industry reports, rotary pumps can improve production rates by up to 30%. This efficiency reduces waste and saves time.

When using rotary pumps, it’s essential to choose the right material. Stainless steel is commonly preferred due to its durability and resistance to corrosion. Some minor imperfections in pump design can impact flow consistency. Regular maintenance checks are necessary to identify wear and tear early. Keeping your equipment in optimal condition ensures smooth operations.

Tips: Always test your pump with the actual product before full-scale use. This helps identify potential issues, such as clogging. Remember to train staff on proper operating procedures. Inadequate training can lead to operational inefficiencies. Ultimately, investing time in understanding rotary pumps can yield significant benefits in your operations.

What are the Benefits of Using Rotary Pumps in Various Industries? - Efficiency and Consistency in Food and Beverage Operations

| Industry | Key Benefits | Application Examples |

|---|---|---|

| Food Processing | Consistent flow, minimal shear, enhanced product integrity | Pumping viscous sauces, purees, and dairy products |

| Beverage Industry | Accurate dosing, prevention of air incorporation | Handling juices, syrups, and carbonated drinks |

| Pharmaceuticals | High precision, contamination control, compliance with regulations | Pumping active ingredients and sterile solutions |

| Cosmetics | Gentle handling of shear-sensitive formulations | Pumping lotions, creams, and gels |

| Chemical Processing | Robust design, ability to handle various viscosities | Pumping adhesives, paints, and viscous chemicals |

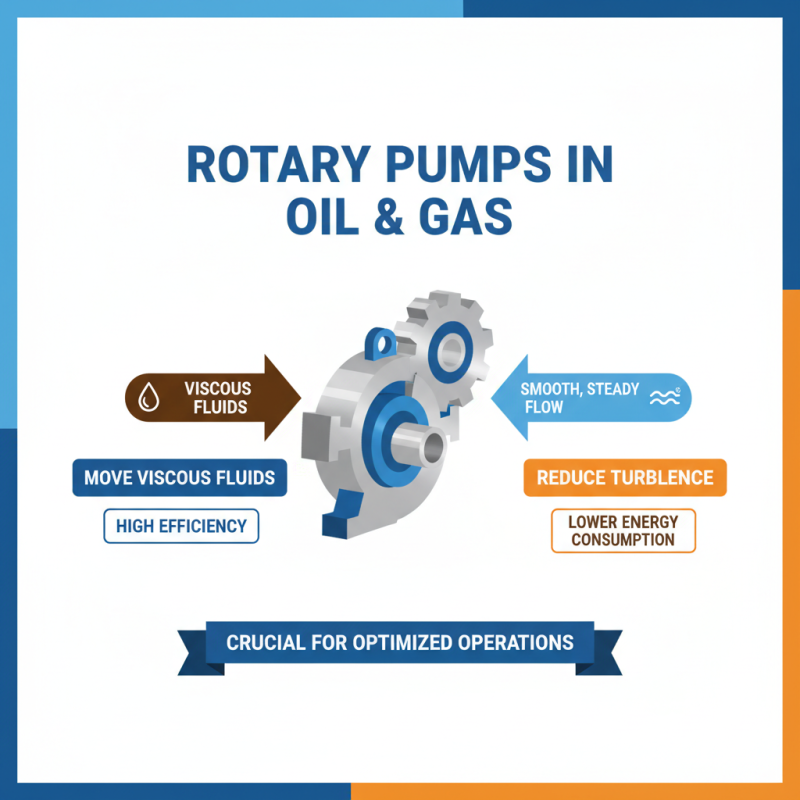

Cost-Effectiveness of Rotary Pumps in Oil and Gas Applications

Rotary pumps play a crucial role in the oil and gas industry. They excel at moving viscous fluids, which are common in this field. This capability makes them highly efficient. Their design allows for smooth and steady flow, reducing turbulence. This can lead to lower energy consumption.

Cost-effectiveness is a significant advantage of rotary pumps. Maintenance costs are generally lower than other pump types. Their simple design requires fewer parts, which reduces the chances of failure. However, users often overlook that not all rotary pumps suit every fluid. Careful selection is essential.

Another point to consider is the sheer variety of rotary pumps available. Each type offers unique benefits, but choosing the wrong one can lead to inefficiencies. Sometimes, users might prioritize price over performance. This can backfire if the pump fails prematurely. Ultimately, understanding specific application needs is vital for maximizing cost-effectiveness.

Enhanced Accuracy in Pharmaceutical Manufacturing with Rotary Pumps

Rotary pumps play a crucial role in the pharmaceutical industry. They ensure precise measurements of fluids, which is vital for consistency in drug production. With the ability to handle various viscosities, these pumps maintain uniform flow rates. This control reduces the risks of errors during manufacturing.

Accurate dosing is necessary for patient safety. Small fluctuations in measurements can lead to significant issues. Rotary pumps minimize these risks with their advanced designs. They often feature adjustable speeds, allowing for customization based on the product being handled.

However, not all rotary pumps operate seamlessly. Regular maintenance is required to avoid wear and tear. Sometimes, operators encounter difficulties in calibration, which can impact performance. Ensuring that all components are in top condition takes time and attention. Investing in training for staff is essential to maximize efficiency.

Durability and Longevity of Rotary Pumps in Water Treatment Facilities

Rotary pumps are a key asset in water treatment facilities. Their durability ensures a long lifespan, even in harsh environments. A report from the Water Environment Federation reveals that rotary pumps can operate effectively for over 15,000 hours with minimal maintenance. This is significant, especially when compared to traditional pumps.

In water treatment, the ability to handle varying fluid characteristics is crucial. Rotary pumps excel in this regard. They can manage high-viscosity fluids and maintain a steady flow rate. This capability is vital for processes like chemical dosing and sludge transfer. Yet, there are challenges. Wear and tear can occur with abrasive materials, demanding regular inspections.

Data suggests that facilities using rotary pumps can achieve energy efficiency gains of up to 30%. This not only reduces operational costs but also lessens environmental impact. Still, facilities must be vigilant about pump selection and maintenance schedules to maximize these benefits. Minor oversights can lead to performance dips. Understanding these intricacies is essential for optimized water treatment operations.

Related Posts

-

What is Vacuum Pump Oil? Understanding Its Types, Uses, and Importance in Industrial Applications

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

7 Essential Tips for Choosing the Best Suction Pump for Your Needs

-

Maximizing Efficiency: The Impact of Industrial Vacuum Blowers on Energy Consumption in Manufacturing

-

How to Choose the Right Oil Pumps for Your Needs?

-

How to Choose the Right Oil Pumps for Your Industrial Needs